E-pos: [email protected]

Wat is die noodsaaklike ertsverpkingsproses?? Eenvoudige deel van inligting

Stel jou voor dat jy 'n skatkis ontdek, Maar dit is gemaak van soliede rots. Bo alles, Dit is in wese rou erts! Dieerts breek proses is die kragtige, noodsaaklike eerste stap in die bevryding van die waardevolle minerale wat daarin vasgevang is. Dit gaan nie net oor brute krag nie; dit is 'n versigtig georkestreerdemineraalvermindering volgorde wat massiewe rotse omskep in hanteerbare, meul-gereed deeltjies. Om hierdie stadium reg te kry, beïnvloed alles stroomaf – doeltreffendheid, koste, en finale herstel. Kom ons breek dit af!

Waarom die ertsbreekproses werklik fundamenteel is?

Eenvoudig gestel, sonder effektiefRots verplettering, die ontginning van waardevolle metale en minerale sal ekonomies onuitvoerbaar of onmoontlik ondoeltreffend wees. Dieverpletteringsproses dien kritieke doeleindes:

- Grootte verkleining: Afbreek groot, onhanteerbare gesteentes in kleiner fragmente.

- Bevryding: Bevryding van teikenmineraalkorrels uit die afvalrots (bende) hulle is binne toegesluit.

- Voorbereiding vir slyp: Die skep van 'n gepaste grootte voer vir maalmeulens, wat die ultra-fyn deeltjies wat nodig is vir skeiding bereik. Maalwerk is energiehonger; doeltreffendprimêre verplettering ensekondêre verplettering verminder die las op hierdie meulens aansienlik.

- Hantering & Vervoer: Kleiner materiaal is baie makliker en veiliger om via vervoerbande te beweeg, vragmotors, of voerders.

Die sleutelstadia van die ertsbreekkring

Dievermindering van ertsgrootte reis vind gewoonlik in verskillende fases plaas:

1. Primêre verplettering: Die eerste magtige slag

- Doelwit: Neem run-of-myn (ROM) erts, wat meter in deursnee kan wees, tot ongeveer 150-250 mm.

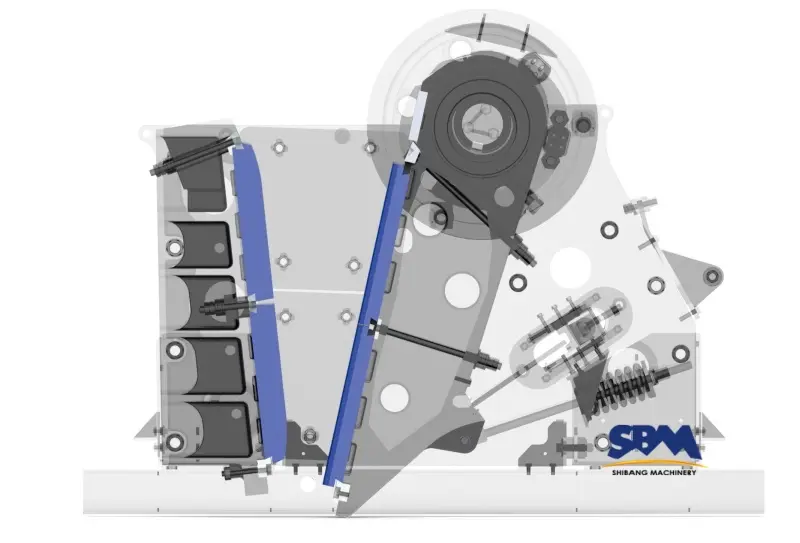

- Die werkpaard: SwaardiensKaakbrekers is die onbetwiste kampioene hier. Dink aan hulle as reuse-neutkrakers, gebruik geweldige drukkrag. SBM China se robuuste PO en PEW reeks kakebeenbrekers is bekend vir hoë kapasiteit en betroubaarheid in hierdie moeilikste aanvanklike stadium.

- Ligging: Word dikwels naby die mynput uitgevoer om vervoerkoste vir oormaat materiaal te verminder.

2. Sekondêre verplettering: Verfyning van die produk

- Doelwit: Neem die primêre gebreekte erts en verminder dit verder, tipies tot 20-50 mm.

- Die Precision Tool: Kegelbrekers uitblink hier. Hulle werk deur rots tussen 'n eksentriese mantel en 'n konkawe bakvoering te druk. Dit maak voorsiening vir beter beheer oor die finale produkgrootte en -vorm. SBM se HPT en HST veelsilinder hidrouliese kegelbrekers bied hoë doeltreffendheid en outomatisering vir optimalesekondêre ertsverwerking.

- Hoekom dit saak maak: Produseer 'n meer eenvormige voer vir tersiêre druk of maal, algehele stroombaandoeltreffendheid te verbeter.

3. Tersiêre/Kwaternêre Verplettering: Die Afronding (Wanneer nodig)

- Doelwit: Bereik selfs fyner groottes (dikwels <10-20mm), veral vir harder ertse of spesifieke maalmeul vereistes. Hierdie stadium is nie altyd nodig vir elke operasie nie.

- Die Spesialiste: FynkopKegelbrekers ofVertikale Shaft Impaktors (VSI's) word algemeen gebruik. VSI's presteer daarin om goed gevormde te produseer, kubiese deeltjies deur klip-op-rots of rots-op-staal vergruising.

Sifting regdeur die breekproses

Jy kan eenvoudig nie oor praat nieerts breek proses effektief sonder om sifting te noem! Ons plaas vibrerende skerms strategies tussen drukstadia (en soms binne 'n verpletterende stadium as 'n geslote lus).

- Doel: Om die gebreekte materiaal volgens grootte te skei.

- Hoe dit werk: Groot materiaal word teruggestuur vir verderverpletterend (skep 'n 'geslote kring'), terwyl korrekte grootte materiaal vorentoe beweeg. Ondermaatse materiaal ('boetes') kan die volgende brekerstadium omseil.

- Die SBM-voordeel: Doeltreffende sifting verseker dat brekers nie energieverwerkingsmateriaal reeds by die teikengrootte mors nie, optimalisering van deurset en vermindering van slytasie. SBM bied 'n reeks van hoë-kapasiteit vibrerende skerms perfek pas by hul brekers.

Die keuse van die regte toerusting: Dit is Vital!

Kies die beste brekers en skerms vir jou spesifiekerts breek proses is uiters belangrik. Oorweeg:

- Ertseienskappe: Hardheid, skuurvermoë, voginhoud, voergrootte, vereiste produkgrootte.

- Kapasiteitsvereistes: Ton per uur benodig.

- Plant Uitleg & Beweeglikheid: Vaste aanleg vs. modulêre/mobiele oplossings.

- Bedryfskoste: Energieverbruik, dra deel lang lewe, onderhoud gemak.

SBM China: Jou vennoot in die optimalisering van die verpletterende reis

SBM Machinery se uitgebreide globale leierskap oor dekades posisioneer dit as 'n topbron vir robuuste, doeltreffend minerale vergruising oplossings. In detail, ontwerp vir hoë uitset en verlaagde bedryfskoste, hul volledige reeks sluit robuuste primêre kakebeenbrekers in, Hidrouliese keëlbrekers, en top-vlak skerms. Buitendien, dit word bereik deur energiedoeltreffendheid en duursame slytonderdele, gekombineer met inherente veiligheid en onderhoudsvriendelike ontwerpe. Om te sien hoe die regte tegnologie verwerkte waarde uit rou ertspotensiaal ontsluit, is werklik dwingend.

Meer as net om klippe te breek

Die erts breek proses is 'n gesofistikeerde, multi-stadium ingenieurswese feat. Spesifiek, dit is die kritieke brug tussen die ontginning van rou erts en die doeltreffende herwinning van waardevolle minerale. Daarom, die primêre te begryp, sekondêr, en tersiêre stadiums – saam met sifting se deurslaggewende rol – bemagtig bedrywighede om opbrengs en kostedoeltreffendheid te maksimeer. Gebruik betroubare, hoë-prestasie toerusting, soos oplossings van SBM China, stel myne in staat om 'n betroubare te vestig verpletterende kring as die hoeksteen van algehele verwerkingsukses. Mens kan nie help om te verwonder oor hoe hierdie formidabele masjiene die Aarde se latente hulpbronne in toeganklike waarde omskep nie. Volgende keer sien jy 'n stuk metaal, onthou die kompleks Rots verplettering reis waarmee dit begin het!