بريد إلكتروني: [email protected]

ما هو حجم الحجر المسحوق للبلاط الخرساني الذي يوفر أقصى قوة?

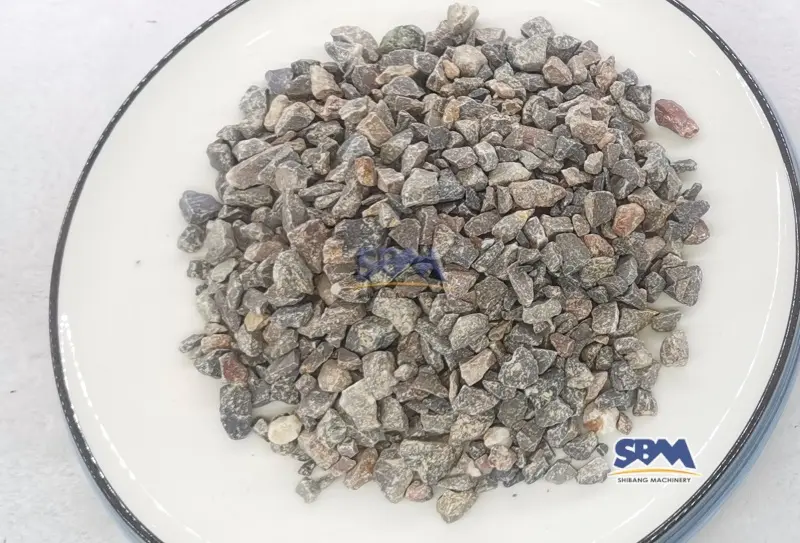

What size crushed stone for concrete slab delivers maximum strength? حجم الحجر المسمار الأنسب للألواح الخرسانية مثل الممرات, الباحات, الأرضيات, إلخ. يكون 19 مم (3/4 بوصة). This is because this size of crushed stone provides the best balance between structural strength and workability. Finer aggregates (على سبيل المثال. 10 mm/3/8 inch) increase density but reduce permeability. Coarser aggregates (على سبيل المثال. 40 mm/1.5 inch) increase permeability but affect surface finish.

Why Crushed Stone Size Matters for Concrete Slabs?

The size of the crushed stone can directly affect the load-bearing capacity, crack resistance, and lifespan of the concrete slab. For concrete slabs that bear heavy loads, such as driveways or industrial floors, mixing 3/4-بوصة من الحجر المسحوق with smaller sizes can increase density by up to 15% compared to a single-size crushed stone.

Optimizing Concrete Performance: Crushed Stone Sizes and Applications

Selecting the right crushed stone size prevents slab sinking and surface spalling. If you want to know more about crushed stone sizes, you can check out the مخطط حجم الحجر المسحوق. Here’s how sizes align with applications:

- 3/8-بوصة (10مم): Ideal for thin decorative slabs (<4 inches thick). Provides smooth finishes but limits drainage.

- 3/4-بوصة (19مم): The universal choice for slabs 4–6 inches thick (الباحات, sidewalks). Balances strength and workability.

- 1.5-بوصة (40مم): Used in deep foundations or roads. Too coarse for most slabs—causes surface unevenness.

طاولة: Crushed Stone Sizes for Concrete Applications

| Stone Size | Slab Thickness | الأفضل ل | Compaction Difficulty |

|---|---|---|---|

| 3/8-بوصة (10مم) | <4 بوصة | Decorative concrete | قليل |

| 3/4-بوصة (19مم) | 4–6 inches | الباحات, الممرات, الأرضيات | معتدل |

| 1.5-بوصة (40مم) | >6 بوصة | Roads, industrial bases | عالي |

Why 3/4-Inch Stone Dominates Slab Construction?

زيادة 70% of residential and commercial slabs use 3/4-بوصة من الحجر المسحوق2. Its angular edges create friction bonds that resist shifting, while its size allows cement paste to coat particles fully. Projects using this size show 20% higher compressive strength than those with larger stones.

From Quarry to Slab: The Journey of 3/4-Inch Stone

- السحق الأساسي: الكسارات الفكية break blasted rock into 6–8-inch chunks.

- سحق ثانوي: Cone crushers reduce chunks to 1–3 inches.

- Tertiary Screening: Vibrating screens separate 3/4-inch particles, with oversize material recirculated.

Modern plants like SBM’s mobile crushers integrate these steps, producing 200–500 tons/hour of perfectly graded stone.

Beyond Size: 4 Critical Factors When Using Crushed Stone in Slabs

- Wash It! Dust or clay coating particles reduces paste adhesion. Opt for stone with <1% silt content.

- Angularity > Smoothness: Jagged edges (from granite/limestone) interlock better than rounded gravel.

- Layer Thickness: للألواح, limit compacted stone base to 6 بوصة. Thicker layers invite settling.

- Moisture Control: Stone should be damp before pouring—bone-dry stone steals water from the mix, weakening hydration.

Matching Crushers to Stone Size: Your Equipment Guide

- كسارات الفك: Create initial 6–8-inch rubble. Use for large-volume primary crushing.

- كسارات مخروطية: Precision reduction to 3/4-inch. Ideal for high-hardness stone like basalt.

- كسارات تصادمية: Produce smaller stones (3/8-بوصة) with cubical shapes for smooth finishes.

طاولة: Crusher Selection by Output Size and Application

| نوع الكسارة | Output Size Range | Best Stone Types | القدرة الإنتاجية |

|---|---|---|---|

| كسارة الفك | 4–8 inches | جرانيت, بازلت حجر بركاني | 100–800 tons/hour |

| مخروط محطم | 3/8-3 بوصات | حجر الكلس, الكوارتزيت | 50–500 tons/hour |

| تأثير محطم | 3/8-1 بوصة | Softer stone, إعادة التدوير | 30–300 tons/hour |

Crushing Your Own Stone: 5 Unbeatable Advantages

- Cost Slashed: On-site crushing cuts transport costs by 40%—no middlemen.

- Tailored Gradations: Blend exact sizes (على سبيل المثال, 3/4-inch mixed with 3/8-inch filler) for optimal slab density.

- Recycle Waste: Crush concrete debris into new aggregate—eco-friendly and ASTM-compliant.

- Consistency Control: Adjust crusher settings daily to maintain size uniformity (±3mm).

- إدارة الغبار: Modern crushers like SBM’s include spray systems, reducing silica dust by 90%.

Crushed Stone vs. الحصى: The Concrete Showdown

- صخرة محطمة (3/4-بوصة): Angular surfaces boost mechanical bonding. Slabs show 30% higher flexural strength than gravel-based concrete.

- الحصى: Rounded edges reduce water demand (good for workability) but decrease crack resistance. Reserve for non-structural slabs.

I’ve seen slabs fail first-hand where contractors substituted river gravel for crushed stone—within a year, cracks spiderwebbed across the surface. Don’t compromise on angular aggregate for load-bearing concrete.

Choosing Your Stone Crusher: 3 Make-or-Break Considerations

- احتياجات الإنتاجية: For slabs under 1,000 sq ft, mobile jaw/cone combos (like SBM’s K Series) handle 150 طن/ساعة.

- Stone Hardness: Granite/basalt demand كسارات مخروطية; softer limestone works with impact crushers.

- Size Flexibility: Look for hydraulic adjustment—change from 3/4-inch to 3/8-inch output in minutes.

Mastering crushed stone size transforms concrete slabs from adequate to exceptional. By locking 3/4-inch stone into your specs, precisely controlling gradation, and leveraging modern crushers, you’ll build slabs that endure decades of use. Every crushing plant I’ve audited that adopted multi-stage screening saw a dramatic drop in slab callbacks—proof that size intelligence pays.

المكتب الرئيسي

واتس اب:+8615225176731

بريد إلكتروني: [email protected]

عنوان: لا. 1688, طريق جاوك الشرقي, حي بودونغ الجديد, شنغهاي, الصين.

موقع إلكتروني: https://www.mill-sbm.com/