بريد إلكتروني: [email protected]

حجر الجرانيت المسحوق

بيت » صخرة محطمة » حجر الجرانيت المسحوق

المحتويات الرئيسية

Crushed Granite Stone is a durable, eco-friendly aggregate for driveways, المناظر الطبيعية, والبناء. Offers superior drainage, 100–250 MPa compressive strength, and versatile sizing for cost-effective, stable surfaces.

If you’re looking for a durable, versatile, and eco-friendly material for your next project, crushed granite stone might just be the way to go. I’ve heard it from my clients time and again. Trust me—it makes a real difference! This guide will go into detail on everything you need to know: from applications and benefits to sizing tips. Let’s get started.

What Exactly Is Crushed Granite Stone?

Crushed granite is a natural aggregate made by mechanically breaking solid granite into angular pieces. Unlike rounded river gravel, its jagged edges snap together to create a stable surface. Crushed granite ranges in size from a fine powder (“weathered granite”) to coarse chunks. Interesting fact: The mineral components of الجرانيت (such as quartz and feldspar) give it its signature mottled appearance and exceptional durability.

قمة 5 Uses for Granite Aggregate

- الممرات & Roads: Its compactibility makes it ideal for base layers.

- المناظر الطبيعية: Perfect for garden paths, الباحات, or decorative ground cover.

- بناء: Used in concrete mixes and drainage systems.

- Erosion Control: Stabilizes slopes and shorelines.

- صابورة السكك الحديدية: Supports tracks due to its weight and drainage properties.

I once replaced my muddy backyard trail withgranite aggregate—zero weeds and all-weather usability!

Why Choose Crushed Granite? Key Benefits

- متانة: Resists weathering and heavy loads (compressive strength: 100–250 MPa).

- صديقة للبيئة: 100% natural and recyclable.

- تصريف المياه: Gaps between particles prevent water pooling.

- Aesthetic Appeal: Rustic charm with color variations (رمادي, لون القرنفل, or gold).

- فعاله من حيث التكلفه: Cheaper than pavers or solid slabs.

Popular Sizes of Granite Gravel and Their Uses

Here’s a quick reference table to matchgranite stone aggregate sizes to your project:

| مقاس (مم) | Common Name | الأفضل ل |

|---|---|---|

| 0–5 | Decomposed Granite | Paths, playgrounds, soil amendment |

| 5-10 | Fine Granite Chips | الممرات, decorative mulch |

| 10–20 | Medium Granite Gravel | قاعدة الطريق, drainage layers |

| 20–40 | Coarse Granite Rock | Landscaping accents, erosion control |

نصيحة: For driveways, pair a 20–40mm base with a 5–10mm top layer for smoothness!

How to Source Quality Crushed Granite Stone?

Not allcrushed granite is created equal! When buying:

- Check Gradation: Ensure uniform particle sizes (ask for sieve analysis reports).

- Verify Hardness: Opt for granite with >6 صلابة موس (like SBM China’s quarries).

- Consider Color: Match your project’s aesthetic—e.g., gray for modern gardens, pink for warm tones.

Apart from this, we can also use manual crushing or jaw crushers (for coarse aggregates) وكسارات المطرقة (for fine aggregates) to crush granite or other ores.

Why Crushers Deliver Superior Crushed Granite Stone?

Unlike hand-crushing, mechanical crushers ensure:

✅Consistent particle size (critical for compaction and drainage).

✅Angular fragments (interlocking stability).

✅Minimal dust/debris (via built-in screens or air filters).

✅Scalable output (from decomposed granite powder to 40mm road base).

3 Crusher Types for Every Project Scale

| يكتب | مقياس المشروع | Input | الإخراج | الأفضل ل | Tip/Hack | يكلف |

|---|---|---|---|---|---|---|

| Portable Jaw Crushers | Small-Medium Projects | Raw granite boulders (≤500mm) | Coarse aggregate (10–40mm) | On-site recycling of demolition waste or quarry leftovers | Add vibrating screen to separate fines (0-5 مم) for pathways | Rent for ~$200/day (ideal for driveways/landscaping) |

| كسارات مخروطية | Medium-Large Production | Pre-crushed chunks (≤150mm) | Uniform medium gravel (5-20 مم) | High-volume projects requiring precise gradation (على سبيل المثال, railroad ballast) | Pair with dust suppression system to reduce silica exposure | – |

| كسارات تصادمية | Fine Aggregate & Specialty Shapes | Medium granite pieces (≤100mm) | Cubic-shaped chips (3–10mm) or decomposed granite (0-5 مم) | Decorative gravel or concrete mixes needing smooth edges | – | – |

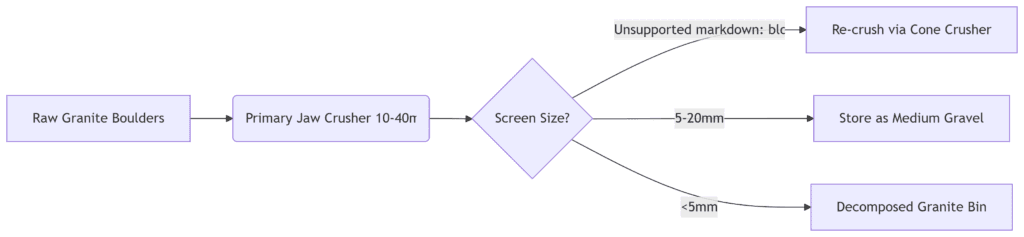

Crusher Workflow: From Raw Rock to Premium Aggregate

Follow this sequence for optimal quality:

ملحوظة: Always test output with a sieve kit—adjust crusher settings if >15% particles deviate from target size.