Correo electrónico: [email protected]

Cómo reciclar mejor los desechos industriales?

¿Qué es el desperdicio industrial?? No es basura: es efectivo enterrado bajo procesos perezosos. Montones de escoria que le cuestan tarifas de vertedero? Estanques de relaves tragando bienes raíces? Scrap metal hauled off for pennies? Enough.Here’s how to better recycle industrial waste and turn liability into cold, hard profit.

What’s Really in Your Industrial Waste Mountain?

- Escoria: That rock-hard leftover from smelting? It’s loaded with trapped metal and minerals begging for liberation.

- Relaves: El “worthless” sludge after extraction? Bull. Residual metals hide there – we just crush and grind finer.

- do&D Rubble: Concrete chunks, rebar spaghetti. Stop paying to dump it. Crush onsite and sell it back to construction.

- Sloppy Sludges: Oily gunk from machining or chemicals. Nasty? Sí. Untreatable? Hell no.

- Scrap Graveyards: Dead machines, circuit boards, shredded metal. That’s not scrap – that’s urban ore.

Why should we recycle industrial waste better?

“Better recycling” means fatter margins. Período.

- Landfill Fees? Gone. Dumping costs $50-$150+/ton. Crushing waste onsite? Pennies.

- Sell What Was “Trash”. Slag aggregate replaces gravel. Reprocessed tailings yield copper or cobalt.

- Regulators Off Your Back. Tightening laws = rising fines. Get ahead or get fined.

- Customers Actually Pay More para “verde” steel made with your recycled slag.

- Mine Your Own Dump. Why beg for volatile raw materials when your waste pile is a resource?

Your Secret Weapon for Industrial Waste Recycling: Crushers and Mills

Talk’s cheap. Let’s break rock. Size reduction isn’t science – it’s brute force with precision.

- trituradoras de quijada: The pitbulls. Chomps concrete, escoria, scrap metal whole. Need to eat a 24-inch slag boulder? Este. (See real-world beasts: SBM Jaw Crushers)

- Trituradoras de Impacto: The ninjas. Perfect for mixed C&D debris. Smashes, shapes, and separates in one pass. Faster setup.Ideal for demo crews. (SBM Impact Crushers)

- trituradoras de cono: The surgeons. por duro, abrasive tailings or granito. Gives precise control over final size.No wasted product.

Molienda? Where Profit Gets Liberated:

- Fábrica de bolas: Old-school tanks. Tumbles steel balls to pulverize slag or tailings. Difícil, simple, eficaz.

- Molinos de rodillos verticales (VRM): Cambiadores de juego. Slams material between rollers and table. Usos30% menos poder than ball mills. Turns slag into premium cement additive (GGBS). Your ROI workhorse. (SBM VRM Grinders)

- Ultra-Fine Grinders: For tailings that laugh at ball mills. Unlocks microns of gold, cobalt, lithium.High capex, higher payback.

Match Your Waste to the Weapon

| Waste Type | Kill Chain | Crush With | Grind With | Sell As |

|---|---|---|---|---|

| Escoria (Alto horno) | Reduce size, free metals | Jaw Crusher → Cone | VRM | GGBS ($60-$120/tonelada), base de la carretera |

| Relaves (Hard Ore) | Crush → Liberate minerals | Trituradora de cono | Ball Mill → Stirred Mill | Copper concentrate, rellenar |

| Relaves (Fine Sludge) | Skip crushing → Classify | —— | Stirred Mill | Critical minerals concentrate |

| do&D Concrete | Crush → Remove rebar | trituradora de impacto | —— | RCA ($15-$30/tonelada) |

| E-Waste (Circuit Boards) | Shred → Separate metals | Molino de martillo | Ultra-Fine Mill | Gold slurry, copper flakes |

Más allá de la trituradora: The Full Profit Pipeline

Crushing/grinding is step one. Here’s your full assault plan:

- Conoce a tu enemigo: Sample waste. Test it.What metals? What minerals? What crap?

- Pre-Sort Ruthlessly: Magnets pull steel. Eddy currents kick out aluminum. Screens scalp oversize.Do this BEFORE crushing – saves hammers.

- Crush Smart: Match crusher to material hardness. Jaw for big slag. Impact for concrete.Wrong tool = downtime + dead bearings.

- Grind to Value: Ball mill for cheap bulk. VRM for high-value powders. Ultra-fine for “impossible” tailings.

- Separate Like a Boss:

- Magnets: Steel recovery (obvious).

- Gravity Tables: Gold/copper from e-waste.

- Froth Flotation: Trick minerals into floating off.

- Sell Aggressively:

- Slag powder → Cement plants

- Crushed concrete → Road builders

- Metal concentrates → Smelters

Lock contracts BEFORE you process.

Charla real: Crushing the Hurdles

Sí, it’s work. Beat these, you win:

- “Machinery Costs Too Much!”

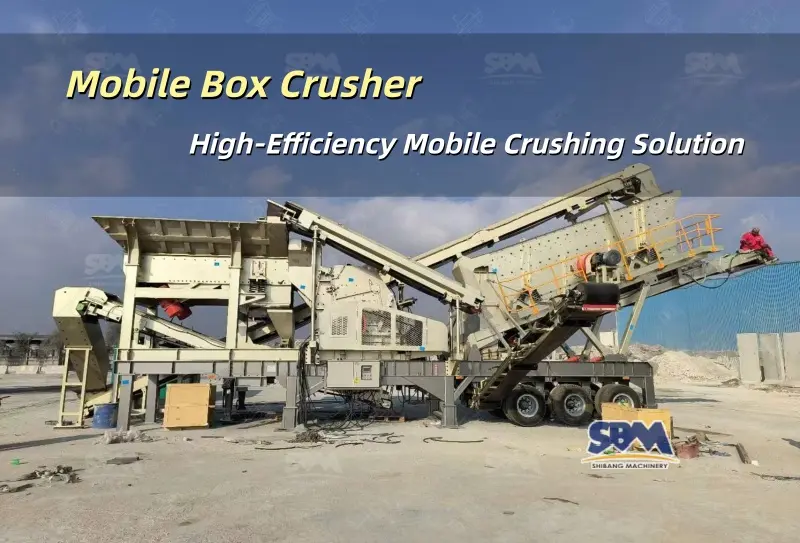

*→ Mobile crushers range in price from $100,000 a $800,000. On-site processing → significantly reduces transportation costs → payback period of less than 12 months.*

→ Phased rollout: Attack highest-value waste first (P.EJ., slag before sludge). - “Our Waste is Too Messy!”

*→ Pre-sort! 80% of recycling fails start here.*

→ Test samples with equipment vendors (SBM does this – Contact Them). - “Who Buys This Stuff?”

→ Cement producers NEED slag (GGBS).

→ Construction craves cheap recycled aggregate.

→ Smelters pay premiums for clean metal concentrates.

Stop Bleeding, Start Earning

Eso “desperdiciar” montón? It’s your next profit center.

- Audit NOW: What waste costs you most?

- Test Samples: What’sen realidad in it?

- Crunch Numbers: Landfill savings + product sales – capex = ?

- Start Small: Buy a mobile crusher (SBM Mobiles). Proceso 500 tons of concrete rubble. Sell RCA. Prove the model.

- Scale Ruthlessly: Reinvest profits into VRM for slag → sell GGBS → dominate.

This isn’t greenwashing. This is margin expansion hiding in plain sight. Your crushers aren’t just machines – they’re profit engines disguised as iron. Feed them waste. Spit out cash.

Ready to mine your dump?