E-mail: [email protected]

Le concasseur à impact PF1210: Comment ses dimensions façonnent l'efficacité de l'exploitation

Imaginez ce: Un site minier éloigné dans la forêt tropicale brésilienne doit traiter le minerai de fer(qui nécessite un concasseur à impact PF1210) mais fait face à des limitations d'espace strictes(En termes de dimensions du concasseur). La solution? A PF1210 impact crusher – not just for its crushing power, but because its 2.8m height clears jungle canopy restrictions. This story exemplifies why crusher dimensions matter beyond technical specs.

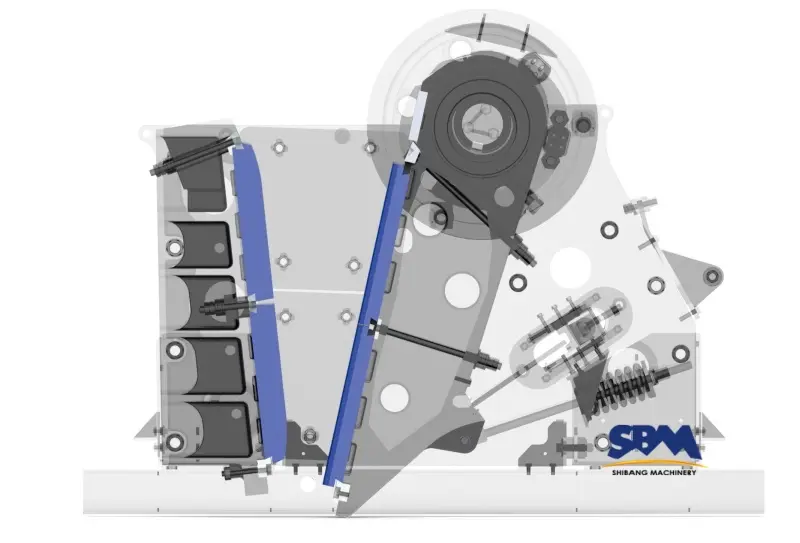

Breaking Down the Blueprint: What 1250mm Rotors Mean for Your Project

Unlike generic “one-size-fits-all” broyeurs, the PF1210’s 1250mm rotor diameter represents a calculated compromise. During field tests in Chilean copper mines, this specific measurement allowed:

- Processing 110t/hour without overloading conveyor systems

- Fitting through 3m-wide tunnel entrances to underground sites

- Maintaining <75dB noise levels in eco-sensitive areas

The 400x1080mm feed opening wasn’t arbitrary either. Swedish quarry operators found it perfectly accommodates the ore raw materials (blasted granite chunks) from Nordic drill patterns, reducing secondary blasting costs by 18%.

When Millimeters Matter: Site-Specific Adaptations

Cas 1: Gold Rush 2.0 in Yukon Permafrost

A Canadian crew retrofitted their PF1210 impact crusher with heated bearing housings (-40°C operation), shrinking the standard 2.16m width to 2.1m for transport via ice roads. The crusher now produces 1.5M tons of gold ore annually – all while fitting in modules helicoptered to site.

Cas 2: Urban Recycling in Tokyo

A demolition contractor modified the discharge height from 2800mm to 2420mm, enabling integration into a 6-story building’s basement. The crusher now processes 800t/day of concrete rubble within city noise ordinances.

The Maintenance Reality Check

While spec sheets tout “easy access”, real technicians tell a different story. The PF1210 impact crusher’s 45° side inspection doors (contre. older models’ 30°) proved crucial during a 24/7 zinc mine operation in Namibia:

- Blow bar replacement time dropped from 3.5 pour 2.2 heures

- Ladder-free access reduced fall risks on slippery sites

- Standard 680mm tool clearance fit impact wrenches used in African mines

Beyond the Tape Measure: Hidden Dimension Impacts

- Vibration Zones: The 2680mm length aligns with South African seismic regulations for broyeur de mine d'or foundations.

- Dust Management: 2800mm height allows direct connection to Mongolian coal mine’s existing baghouse systems.

- Fuel Logistics: In Papua New Guinea’s diesel-dependent mines, the crusher’s compact footprint enabled 35% smaller generator setups.

Operator’s Notebook: Practical Dimension Hacks

- “We use the 2160mm width as a reference for haul road widths” – Site Manager, Indonesian nickel mine

- “The feed opening height matches our excavator bucket dump angles” – Foreman, Texas limestone quarry

- “Discharge chute modifications based on crusher height increased our screening efficiency by 11%” – Engineer, Russian diamond project

Critical Questions Contractors Actually Ask

Why not choose a bigger crusher?

At a Zambian copper mine, using two PF1210 impact crushers (total 2600mm width) outproduced a single larger dimensions crusher while allowing staggered maintenance.

How do dimensions affect liner costs?

The rotor’s 1250mm diameter uses 7% fewer wear plates than 1300mm models but lasts longer due to optimized material flow.

Can it handle non-standard materials?

A Scottish whisky distillery crushes peat bricks (low abrasiveness but high moisture) by adjusting the PF1210’s cavity dimensions – no hardware changes needed.

The Future of Crusher Sizing

Recent upgrades focus ondimensional intelligence rather than pure scale:

- Laser-scanned cavity adjustments for Brazilian iron ore variations

- Smart shims auto-adjusting crusher width during Chilean earthquake tremors

- 3D-printed spacer kits adapting PF1210s to obsolete conveyor systems in Indian steel plants

Bureau du siège social

WhatsApp:+8615225176731

E-mail: [email protected]

Adresse: Non. 1688, Gaoke East Road, Nouveau quartier de Pudong, Shangai, Chine.

Site Internet: https://www.mill-sbm.com/