E-mail: [email protected]

Scories

Contenu principal

Walk by any old steel mill, and you’ll spot them: giant grey-black piles shining in the sunlight. For years, we saw this scories as nothing but trash – an ugly reminder of industry’s mess. I’ve stood on these heaps in Dortmund and Pittsburgh, crushing glassy bits under my boots. What struck me wasn’t the smell or dust; it was how wrong this was. Here was stuff tougher than natural rock, steadier than mined calcaire, yet we were dumping it underground. That old story’s now falling apart faster than bad concrete. Après 20 years working with crushed materials, I’ve watched slag’s comeback myself – from landfill junk to vital construction material. This isn’t just reuse; it’s industry magic.

Slag Demystified: What Mills Don’t Tell You

Slag isn’t ‘waste.’ It’s the natural result of cleaning metals. When raw ore meets super-high heat (over 1,500°C in furnaces), unwanted stuff melts together into a hot liquid mix of silicates, calcium oxides, et l'aluminium. This lava-like flow gets removed from pure metal – like skimming fat from soup. But here’s what factories won’t tell you: slag’s makeup is unique. German slag differs from Indian slag because of:

- Where the ore comes from

- Materials added during melting

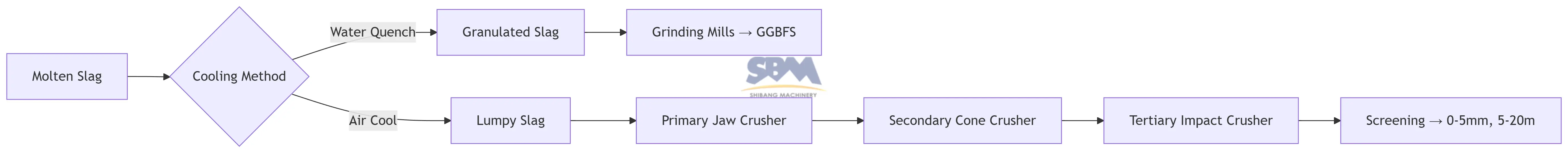

- How it’s cooled (water spray vs. air cooling)

I’ve tested slag with 40% silica against types full of calcium compounds. This difference isn’t bad – it’s useful. Dutch road builders specifically order electric furnace slag for seaside roads because its extra iron fights salt damage better than regular stone.

Slag Types: A Field Guide for Engineers

Blast Furnace Slag (BFS): The Cement Saviour

Formation: Molten slag water-quenched at 1,000°C → glassy granules (GBFS).

Pour la pointe: GBFS reactivity depends onglass content. Aim for >90% vitreous material – check mill certificates. Lower grades cause slow strength gain.

Steel Slag: The Road Warrior

The Expansion Myth: Oui, fresh BOF slags expands like baking dough. Pourquoi? Free lime (CaO) hydration. But here’s the fix:

- Hot-stage processing: Inject CO2 during cooling → forms stable calcite

- Weathering: Minimum 6-month outdoor exposure (monitor pH < 10.5)

- Accelerated aging: Steam curing at 80°C for 48 heures

Field Observation: Japan’s Tohoku Expressway uses 100% aged steel slag aggregate. After the 2011 quake, sections with slag base showed 70% less cracking than gravel-based stretches.

The Underdogs

- Copper Slag: Blasting abrasive so aggressive it strips hull paint in half the time of garnet sand. Requires dust suppression systems.

- Ferronickel Slag: Indonesia ships this to Dubai as road base – its high MgO content prevents bitumen stripping in heat.

Processing Breakdown: Where Profit is Made

Crushing Circuits – The Heartbeat

Crusher Selection Truths:

- Concasseurs à mâchoires: Best for >800mm lumpy slag. Wear cost: $0.18-0.30/tonne

- Rupture de cône: Ideal for 50-250mm feed. Produce 60% cubical aggregate

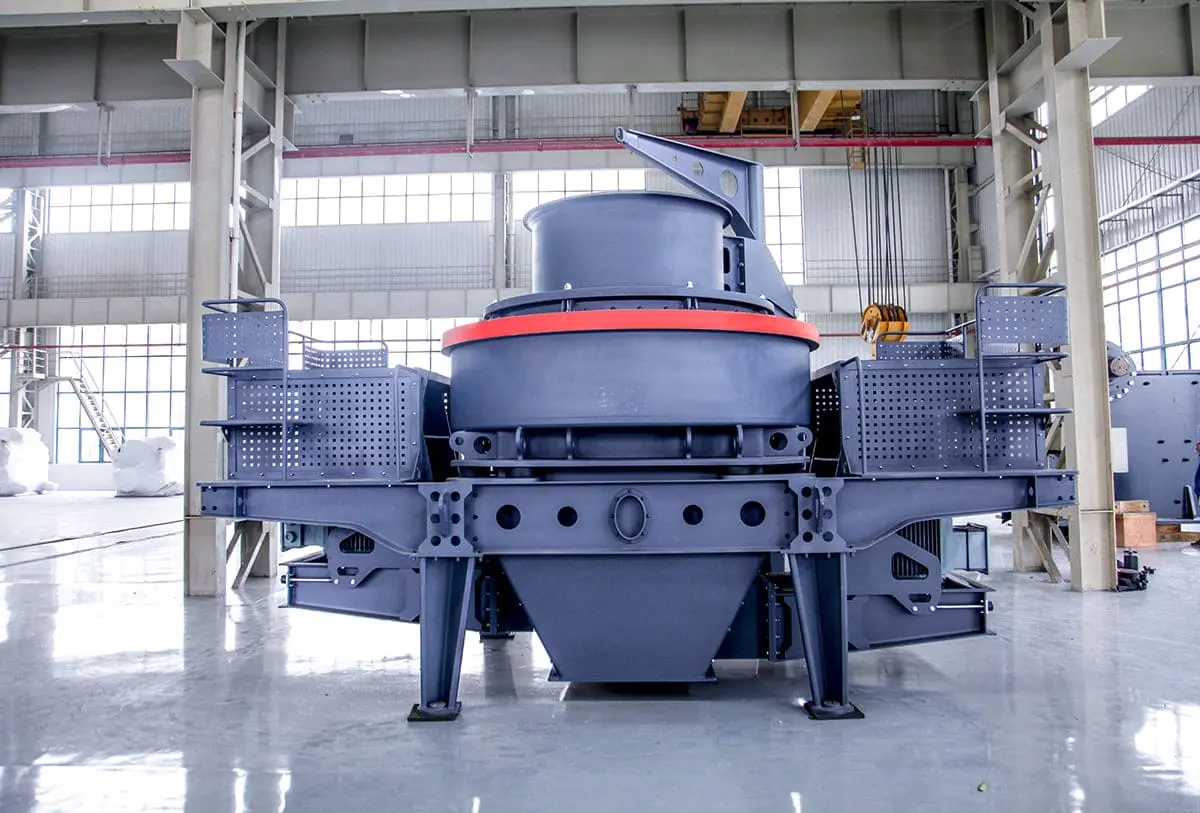

- Concasseurs VSI: Essential for road aggregates. Enhances particle shape but costs 40% more in wear parts

Operator Hack: Run slags through electromagnetavant concassage secondaire. Recovered metal scrap offsets 15-30% of processing costs.

The Weathering Yard Dilemma

Steel slag stockpiles aren’t just sitting – they’re chemically evolving. Smart plants:

- Install drainage layers under piles

- Monitor pile temperatures (target <70° C)

- Test expansion monthly (EN 1744-1 test)

Coût: Weathering adds $1.50-4.00/ton but prevents $20+/ton in liability claims.

Slag Cement: The Carbon Killer

Why GGBFS Beats Fly Ash

| Propriété | GGBFS (50% blend) | Class F Fly Ash | Portland Cement |

|---|---|---|---|

| 28-day Strength | 42 MPa | 38 MPa | 48 MPa |

| Chloride Resistance | 90% reduction | 70% reduction | Base de base |

| CO2 Emissions | 380 kg/ton | 410 kg/ton | 830 kg/ton |

| Heat Hydration | Low | Modéré | Haut |

The Grinding Reality

Producing high-reactivity GGBFS requires:

- Vertical roller mills (not ball mills)

- 4,500-5,000 Blaine fineness

- Moisture control <0.5%

Energy Penalty: Grinding consumes 35-50 kWh/ton – still 60% less than OPC production.

Aggregates That Outperform Nature

Roads That Bite Back

Steel slag’s PSV (Polished Stone Value) de 68-72 beats granit (50-55). UK’s Highways Agency mandates slags on M25 curves after wet-season skid crashes dropped 45%.

Concrete’s Secret Weapon

Air-cooled BFS aggregate:

- Low thermal expansion (9 μm/m°C vs limestone’s 12)

- Alkali-silica reaction neutralization

Étude de cas: Dubai’s Burj Khalifa used 340,000 m³ of BFS concrete to combat 50°C setting temperatures.

Beyond Construction: Unusual Profit Streams

Farming’s pH Fixer

Steel slag’s 8.5-11.5 pH makes it perfect for acidic soils. Malaysia’s palm oil plantations apply 2 tons/hectare:

- Raises soil pH from 4.2 → 6.0 in 6 mois

- Adds soluble silicon for stalk strength

Caution: Test for heavy metals – Cd < 2 mg/kg, Cr < 80 mg/kg.

Mineral Wool’s Dirty Secret

70% of stone wool is actually slag wool. Production energy:

- basalt: 2,800 Kwh / tonne

- Slag-based: 1,100 Kwh / tonne

Conseil: Use slags with 38-42% CaO for optimal fiberization.

Equipment Deep Dive: Making Crushers Last

Slag’s Wear Mechanisms

- Abrasion: SiO2 content >18% accelerates wear

- Impact: Uncrushed metal “tramp” damages rotors

- Corrosion: Sulfides attack manganese steel

SBM China’s Edge (https://www.mill-sbm.com)

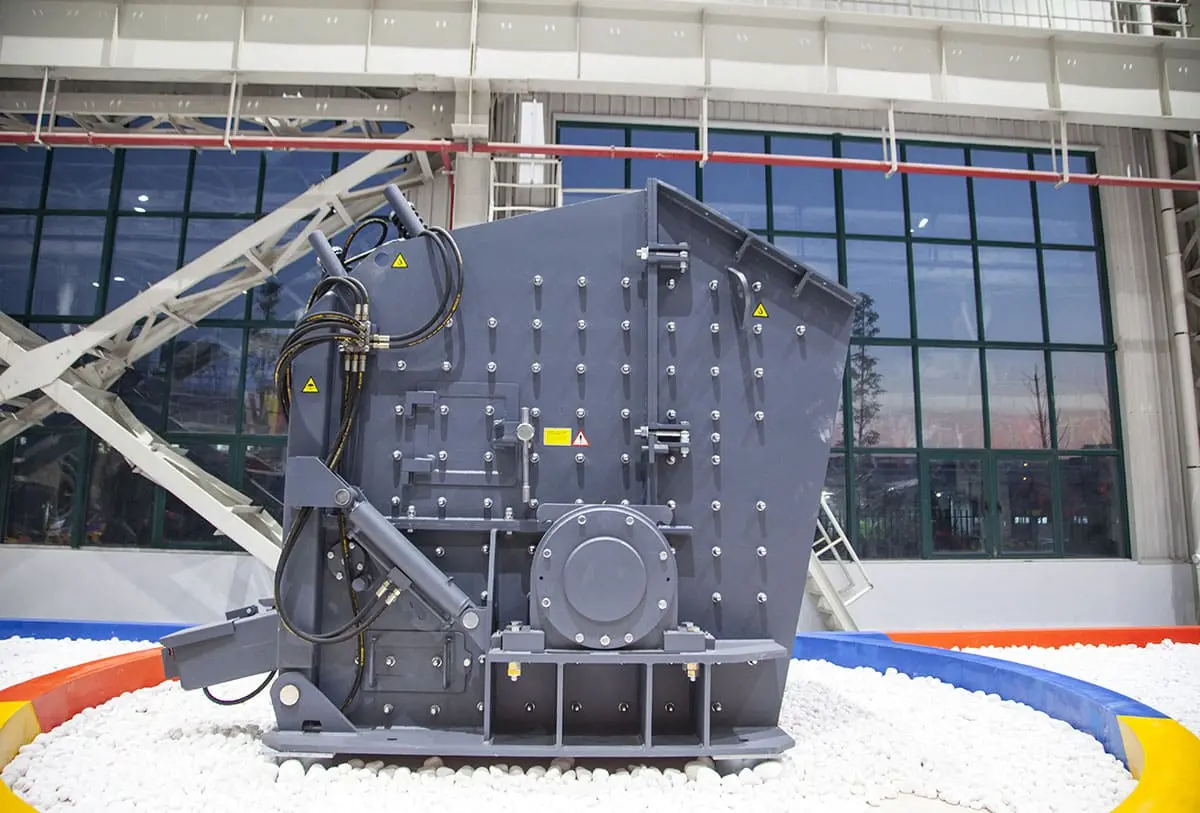

Le concasseurs à percussion handle slags better because:

- Hybrid breaker plates (ceramic inserts + manganese)

- Rotor impact tips welded with Hardox 500

- Vibration sensors trigger metal detection shutdown

Hack de maintenance: Schedule hammer rotation every 250 hours – extends life by 3x.

The Real Economics of Slag

Pricing Power

| Product | Price (USD/ton) | vs Material |

|---|---|---|

| GGBFS | $55-75 | 15% below OPC |

| Steel Slag Aggregate | $12-18 | 20% below granite |

| Copper Slag Abrasive | $80-110 | 30% below garnet |

Hidden Revenue Streams

- Carbon credits: 1 ton GGBFS = 0.65 carbon credits

- Récupération des métaux: $15-40/ton from ferrous scrap

- Landfill avoidance fees: $7-20/tonne

The Future Is Pre-Activated

Leading research (Fraunhofer Institute, 2023) showsmechanochemical activation could revolutionize slag:

- High-pressure grinding to nano-particles

- Chemical activators (Na2SO4 or KOH)

- Résultat: 7-day strength equal to OPC

This eliminates grinding costs – the final barrier to 100% slag cements.

Waste is Just Resource in Disguise

Last year, I visited a Tokyo data center made with 92% slag concrete – cool inside, no cracks, standing strong through earthquakes. Nearby, rice fields fed with slag glowed bright green. This isn’t just for show; it’s practical resourcefulness. Le 2.5 billion tons of old slag piles worldwide aren’t problems – they’re unused resource banks. With modern crushers and processing, we’re not just recycling slags; we’re reusing our own industrial leftovers. Le “déchets” era is finished. Welcome to the age of valuable materials.