Имэйл: [email protected]

Нөлөөллийн бутлаг, шийдлийн нийтлэг дутагдал

Impact crushers play a key role in today’s mining and quarry jobs, turning large stones and ores into materials that can actually be used. But even though these machines are tough, they sometimes run into issues that can stop work and cut into profits. Knowing what typical impact crusher problems are, and how to fix them, helps reduce downtime, save on repairs, and make these machines last longer.

Why Impact Crushers Faults Matter?

If an impact crusher fails, production halts, costs rise, and site safety can be compromised. Quick troubleshooting and regular maintenance are essential for keeping operations efficient.

Common Faults of Impact Crushers

Нөхцөл “impact crusher faults” covers everything from abnormal vibrations and overheating bearings, to jammed chambers and excess wear. Let’s break down each fault, its causes, and the best solutions to keep crushers running smoothly.

Irregular Vibration

Abnormal vibration is a frequent issue. It usually points to uneven feed size, blow bar wear, rotor imbalance, or a loose foundation.

Хэт халах

Hot bearings are a classic crusher problem. Most often, the culprits are insufficient lubrication, broken bearings, or debris in the lubrication system.

Product Size Variation

When the final product from an impact crusher becomes too large or too inconsistent, worn blow bars or too-wide gap settings may be the root cause.

V-belt Issues

V-belt problems cause loss of power or sudden stops. This usually results from worn or incorrectly installed belts.

- Common causes: Belt wear, poor alignment during installation.

- Шийгэлэл: Replace V-belts, ensure belts and pulleys are in the same plane during setup.

Crushing Cavity Blockage

Material blockages reduce throughput and can potentially damage the machine. Чийг, наалдамхай, or large particles often trigger blockages.

- Common causes: Wet or sticky material, excessive feed size, high feed rate.

- Шийгэлэл: Pre-dry material, crush oversized feed, regulate feed rate/speed.

Noise and Slapping in the Cavity

Sudden, loud noises or ‘slapping’ sounds inside the crusher typically mean something’s entered that shouldn’t, like metal debris, or the impact plate has come loose.

Common Faults and Solutions Table of Impact Crushers

| Гэмтэл | Common Causes | Practical Solutions |

|---|---|---|

| Abnormal vibration | Oversize feed, worn blow bars | Screen material, replace bars, rebalance |

| Bearing overheating | Insufficient oil, broken bearing | Add/change oil, replace bearing |

| Product size variation | Gap too wide, worn bars | Adjust gap, repair/replace bars |

| V-belt overturn | Worn belt, poor installation | Install correctly, replace belt |

| Crushing cavity blockage | Sticky/large feed, high feed rate | Pre-process material, regulate feed |

| Loud cavity slaps | Debris, loose impact plate | Clean cavity, secure plate |

| Crusher won’t start | Blockage, цахилгаан, rotor stuck | Remove blockage, fix wires, free rotor |

Selecting an Impact Crusher: Бүтээгдэхүүний параметрүүд

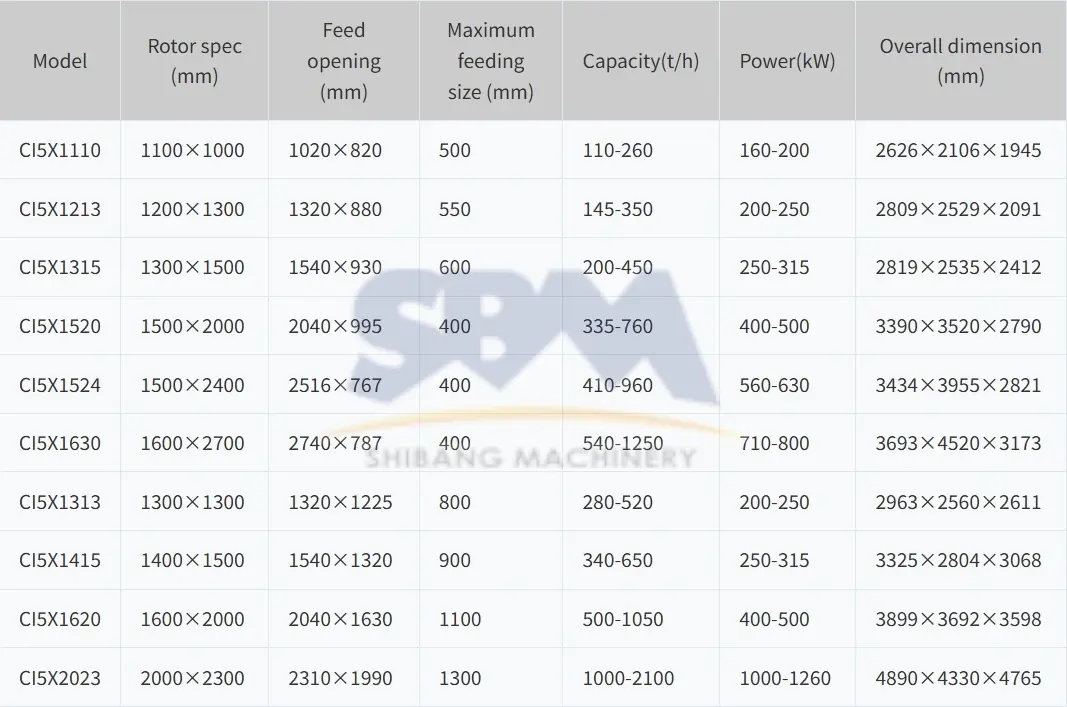

Understanding machine specifications helps users select the right impact crusher for their site. Here are key parameters, using models from SBM for reference:

| Загвар | Ротор хар (мм) | Оролтын хэмжээ (мм) | Input Size Max (мм) | Хүчин чадал (т/ц) | Хүч (kw) |

|---|---|---|---|---|---|

| Ci5x1315 | 1300 × 1500 | 1540 × 930 | 600 (≤300 санал болгож байна) | 250-350 | 250-315 |

| Ci5x1415 | 1400 × 1500 | 1540 × 1320 | 900 (≤600 санал болгосон) | 350-550 | 250-315 |

Product Parameter Chart

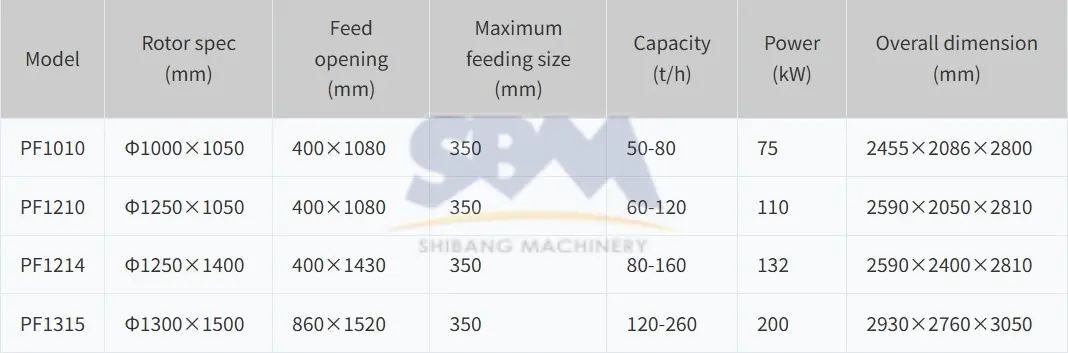

Pf нөлөөллийн crusher Параметрүүд

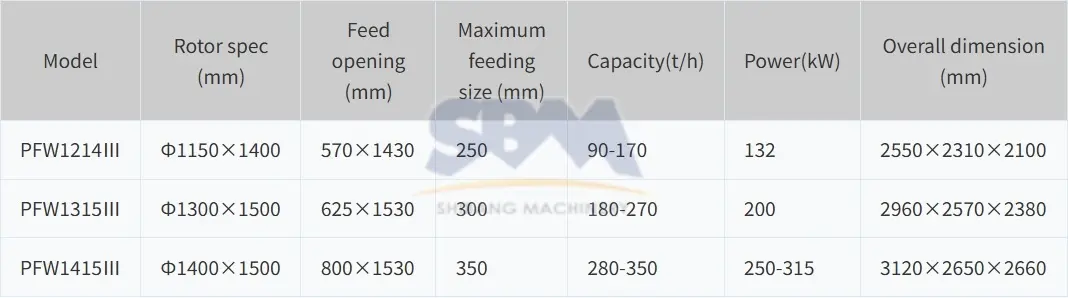

PFW цохилтот бутлуур Параметрүүд

CI5X цохилтот бутлуур Параметрүүд

Preventive Maintenance Tips

Regular checks keep crushers performing and reduce costly failures:

- Inspect blow bars weekly for wear and replace before they become thin.

- Monitor bearing temperature: sustained heat means underlying issues.

- Tighten all bolts at least once per week.

- Screen feed material to prevent oversized pieces entering.

- Use oil recommended by manufacturer, replacing at intervals.

- Keep electrical inputs stable; use surge protectors if available.

Real-world Troubleshooting Scenarios

Operators often deal with blockages or stoppages during wet weather because the material being fed in is too damp, and many sites have more downtime in busy seasons due to parts wearing out. Fixing the real problem right away—such as changing worn parts or adjusting how material is fed—helps avoid long delays and keeps the crusher working.

How Faults Impact Operational Efficiency

Every hour the crusher is down can lead to money loss. Checking the machine often, acting quickly when there’s a problem, and planning repairs for less busy times can save a lot over the year. Teams that look after the equipment before issues get serious get better results and happier customers.

Advanced Solutions and Upgrades

Some problems can almost be avoided with smart improvements:

- Choose blow bars made with strong chrome—they hold up better when working with tough materials.

- Use automatic systems to add oil, so staff don’t have to check by hand.

- Try digital control panels that give warnings about shaking, heat, or electrical problems right away.

Мөн, ask the maker about any service plans or warranties that could help in the long run.

Faqs

Worn blow bars and bearing temperature issues top the list.

Weekly inspection is standard—more often for hard rock sites.

Тиймээ; automated monitoring lets staff spot issues before they become expensive faults.

Most downtime can be shortened or avoided with regular checks and quick troubleshooting.

Дүгнэлт

Impact crushers are super useful in mining and quarry jobs, but only if they are working well. Knowing the usual problems, how to spot them, and how to fix them fast is key for getting more done and making better profits. Operators who learn these basic skills can keep machines working with little stoppage and get the most out of every job.