E-mail: [email protected]

Análise de vibração do triturador de mandíbula fixo: Aumentando o desempenho e a longevidade

A análise de vibração é uma ferramenta crítica para garantir a confiabilidade e a eficiência do triturador de mandíbula fixa nas indústrias de mineração e construção. Monitorando e interpretando padrões de vibração, operators can detect issues early, reduce unplanned downtime, and extend equipment lifespan. This article explores practical techniques, global case studies, and actionable insights for integrating vibration analysis into your maintenance strategy.

Why Vibration Analysis Matters for Fixed Jaw Crushers

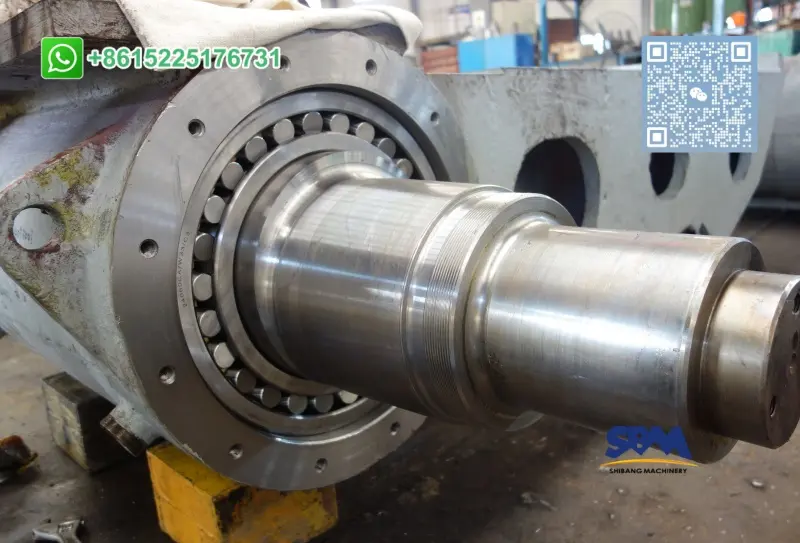

Fixed jaw crushers are robust machines designed to crush hard materials like granite, basalto, e concrete into gravel or aggregates. No entanto, their heavy-duty operation generates significant mechanical stress, leading to wear on components like the fixed jaw plate, eixo excêntrico, e rolamentos. Excessive vibration can accelerate component degradation, causing:

- Premature failure of bearings or liners

- Misalignment of the crushing chamber

- Reduced crushing efficiency and uneven output

Por exemplo, a quarry in Australia reported a 30% increase in maintenance costs due to undetected bearing wear in their fixed jaw crusher. Implementing vibration analysis helped them identify imbalances early, saving $120,000 annually in repairs.

Key Techniques for Effective Vibration Analysis

1. Time-Synchronous Averaging for Rotational Component Monitoring

Fixed jaw crushers rely on rotating parts like the eccentric shaft and flywheel. Time-synchronous averaging (TSA) isolates vibration signals synchronized with shaft rotation, enabling precise detection of irregularities such as:

- Imbalanced flywheels

- Eccentric shaft misalignment

- Worn toggle plates

A study in Brazil used TSA to diagnose a cracked eccentric shaft in a PEX-250×1000 jaw crusher, preventing catastrophic failure.

2. Envelope Spectrum Analysis for Bearing Health

Bearings in fixed jaw crushers are prone to fatigue due to high loads. Envelope spectrum analysis identifies high-frequency vibrations caused by bearing defects, como:

- Spalling or pitting on raceways

- Cage damage

- Lubrication failures

In a Canadian mining operation, this method detected early-stage bearing wear in a PE-600×900 crusher, reducing replacement costs by 45%.

3. Modal Analysis for Structural Integrity

Fixed jaw crusher frames and jaw plates must withstand intense forces. Modal analysis evaluates natural frequencies and damping ratios to prevent resonance, which can lead to structural cracks. Por exemplo, a German cement plant used modal testing to optimize the design of a PE-1200×1500 crusher, achieving a 20% longer service life.

Estudos de caso globais: Lessons from the Field

Caso 1: Reducing Downtime in a U.S. Pedreira de Granito

A granite processing facility in Texas experienced frequent breakdowns in their fixed jaw crusher due to uneven material feed. Vibration analysis revealed excessive torsional vibrations in the eccentric shaft. By adjusting the feed rate and replacing worn jaw plates, downtime decreased by 60%.

Caso 2: Optimizing a Fixed Crusher in South Africa

A gold mine in Johannesburg used vibration diagnostics to address premature wear in their PE-900×1200 crusher. Analysis identified misaligned toggle plates and imbalanced flywheels. Realigning components and upgrading to high-manganese steel jaw plates improved throughput by 25%.

Practical Tips for Implementing Vibration Analysis

- Integrate Sensors Strategically

Mount accelerometers on critical components like the bearing housings, quadro, and moving jaw. Wireless sensors offer flexibility for real-time monitoring in harsh environments. - Baseline Data Collection

Establish baseline vibration levels during normal operation. Compare future readings to detect anomalies early. - Combine with Preventive Maintenance

Schedule inspections alongside vibration checks. Por exemplo, inspect the fixed jaw plate and toggle plates every 500 horário de funcionamento. - Train Operators in Diagnostics

Equip your team with tools like frequency spectrum analyzers and training on interpreting vibration trends.

Linking Vibration Analysis to Broader Crusher Management

To maximize the benefits of vibration analysis, pair it with:

- Proper Installation (See: Installing a Jaw Crusher for guidelines)

- Regular Lubrication Protocols

- Material Feed Optimization

Adicionalmente, consider whether a mobile jaw crusher ou fixed jaw crusher better suits your project (Compare: Crushers de mandíbula móvel vs fixo). For cost-conscious operations, evaluate Usado vs novos trituradores de queixo to balance upfront investment and long-term reliability.

Análise de vibração do triturador de mandíbula fixo

Vibration analysis is not just a technical exercise—it’s a cost-saving strategy that enhances the performance of fixed jaw crushers. By adopting advanced diagnostic techniques and learning from global case studies, operators can minimize downtime, extend component life, and maintain consistent output quality. Start small: implement basic vibration monitoring today, and gradually scale to predictive maintenance models for long-term success.

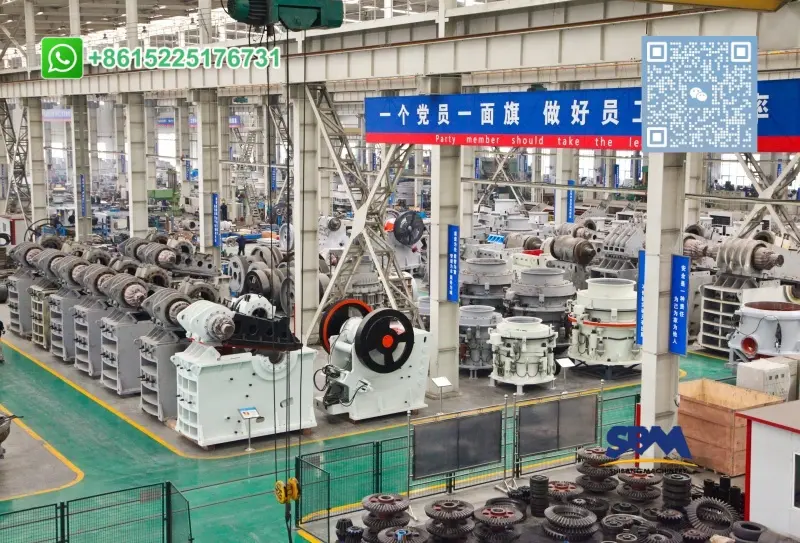

Sede Escritório

Whatsapp:+8615225176731

E-mail: [email protected]

Endereço: Não. 1688, Gaoke East Road, Novo distrito de Pudong, Xangai, China.

Local na rede Internet: https://www.mill-sbm.com/