E-mail: [email protected]

Como funciona o britador de mandíbula?

Before we understand “how does jaw crusher work?”, we need to understand what is a jaw crusher and the basic components of a jaw crusher. Then let’s take a look at the types of jaw breakers.

What is a jaw crusher?

Jaw crusher is a commonly used mining machinery and equipment, which crushes larger stones or ores through the mutual extrusion of fixed jaws and movable jaws. Its main function is to reduce the size of mined ore for processing or transportation. Trituradores da mandíbula (for sale) are used to great effect in mines and quarries as well as in recycling processes where the reduction of bulky materials is required. The crushing equipment is widely used in mining, metalurgia, materiais de construção, construction and other industries.

Basic components of jaw crusher

- Fixed jaw and movable jaw

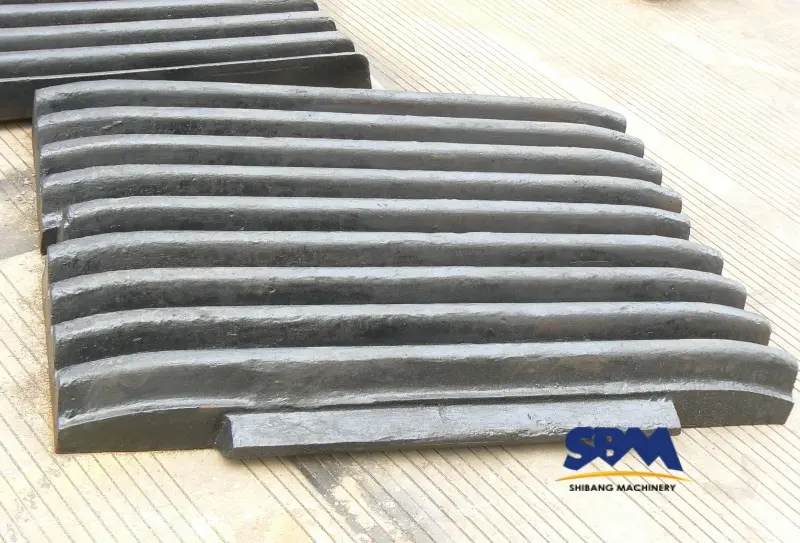

- Jaw liner

- Eccentric shaft

- Drive pulley

- Bracket

How does a jaw crusher work?

After having a basic understanding of the jaw crusher machine, let’s see how the jaw crusher works.

Feeding stage

The ore or rock to be crushed enters the crushing chamber (the volume or cavity between the two jaws) through the vibrating grid feeder. The power provided by the motor rotates the eccentric shaft. As the eccentric shaft rotates, the movable jaw reciprocates.

Crushing stage

At this time, the ore or rock enters the crushing chamber. The movable jaw begins to exert pressure on the rock in the crushing chamber. The ore is squeezed into smaller pieces and gradually flows down to the lower discharge port.

Discharging stage

After the ore is crushed to a set size, it is discharged from the crushing chamber through the lower discharge port. The size of the final product can be pre-set.

How to adjust the discharge size?

Use wedges or hydraulic systems to adjust the gap between the two jaws.

SBM jaw crushers include safety features such as toggle plates. It protects the crusher from overload or uncrushable materials. Jaw crushers are heavy machines, so regular maintenance ensures that the jaw crusher operates efficiently. Maintenance operations include lubricating bearings, checking jaw wear, and tightening or replacing any loose or worn parts.

Types of Jaw Crusher

Triturador de mandíbula PE

Como britador primário clássico com desempenho estável, O britador de mandíbula PE é amplamente utilizado para triturar minérios metálicos e não metálicos, bem como agregados de construção ou para fazer areia artificial.

Triturador de mandíbula PEW

PEW Jaw Crusher é uma nova máquina de britagem desenvolvida pela SBM, o fabricante do britador de mandíbula, após o lançamento do britador de mandíbula tradicional. Além do mais, this jaw crusher is a perfect combination of modern science and technology and the production practice, which can better satisfy the automatic production demands of vast customers.

Britador de mandíbulas C6X

Todos os índices do britador de mandíbula C6X em estrutura e eficiência de produção apresentam tecnologias modernas avançadas. Então, SBM’s C6X Jaw Crusher can solve such problems of the existing universal jaw crushers as low production efficiency, difícil instalação e manutenção. Atualmente, C6X Jaw Crusher is the ideal coarse crushing machine at domestic market.

Sede Escritório

Whatsapp:+8615225176731

E-mail: [email protected]

Endereço: Não. 1688, Gaoke East Road, Novo distrito de Pudong, Xangai, China.

Local na rede Internet: https://www.mill-sbm.com/