E-mail: [email protected]

Guia de seleção de placas da mandíbula: Otimize o desempenho para sua operação de esmagamento

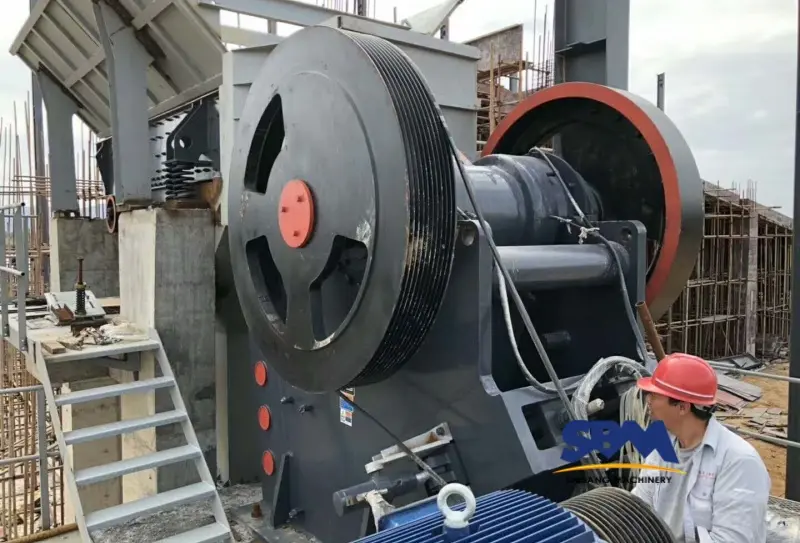

Escolher as placas da mandíbula certa pode aumentar seueficiência de esmagamento por 25-40% enquanto reduz os custos de reposição. Isso abrangenteGuia de seleção de placas da mandíbula explica como a composição material, Projeto do perfil de dente, e as condições operacionais determinam a longevidade da placa. Se você está operando um triturador de mandíbula C6X ou modelos mais antigos, Essas idéias ajudarão você a tomar decisões informadas.

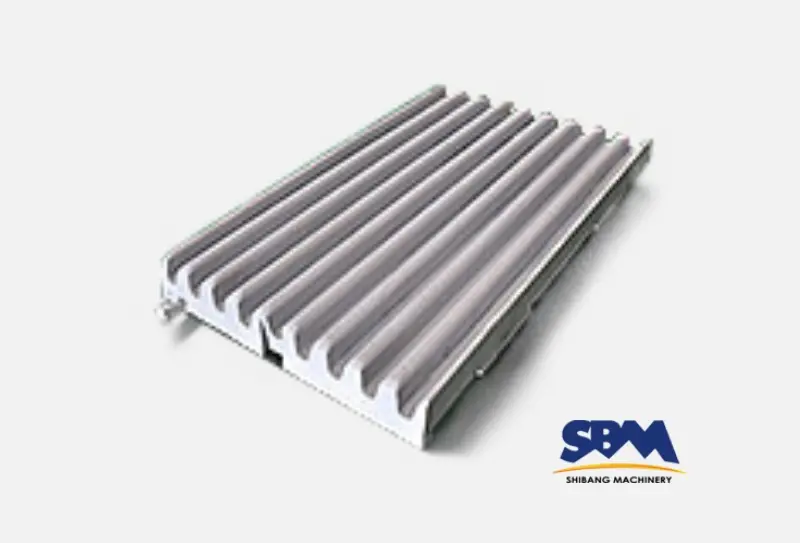

Fatores -chave na seleção de placas da mandíbula

Escolhas de composição do material

As placas de mandíbulas modernas usam três materiais primários:

- Aço de Manganês (14-18%): Ideal para uso geralAplicações de pedreira, suporta 50-70k toneladas antes da substituição

- Liga de ferro cromo: 30% Vida por vida útil mais longa em materiais abrasivos como granito

- Aprimorado em cerâmica: Reduz o desgaste por 45% em operações de conteúdo de alta sílica

Considerações sobre Projeto de Dente Projeto

A configuração do dente da placa afeta diretamente seuMecanismo de trabalho do triturador:

| Tipo de perfil | Melhor para | Faixa de tamanho de saída |

|---|---|---|

| Direto | Esmagamento primário | 150-300 milímetros |

| Acenou | Redução secundária | 50-120 milímetros |

| Híbrido | Alimentos de material misto | 30-150 milímetros |

4-Processo de seleção de etapas

- Analise o material de alimentação: Teste a dureza (escala de Mohs) e abrasividade

- Determine o tipo de triturador: Crusher da mandíbula da série C6X requer sistemas específicos de travamento de placas

- Calcule a vida econômica: Balance custo inicial vs toneladas esmagadas/$

- Verifique a compatibilidade: Verifique as dimensões do sistema de montagem (± 2 mm de tolerância)

Sinergia de manutenção: Pratos e saúde do triturador

ApropriadoManutenção do triturador da mandíbula estende a vida útil da placa por 60%:

- Gire as placas a cada 200-300 horário de funcionamento

- Mantenha as configurações corretas do CSS (afeta os padrões de desgaste)

- Use ferramentas de alinhamento a laser para instalação precisa

Estudo de caso: Otimização de pedreira em granito

Uma operação brasileira alcançada 32% redução de custo por:

- Mudança das placas padrão MN14 para MN18CR2

- Implementando medições de desgaste quinzenais

- Sincronização de substituições com tempo de inatividade de manutenção programado

Técnicas de monitoramento avançado

- 3D Vesquisamento de desgaste para análise de espessura restante precisa

- Modelos de previsão de taxa de desgaste movidos a IA

- Teste de dureza ultrassônica para verificação de material

Erros de seleção comuns

- Escolhendo placas baratas que precisam de 3x de substituição mais frequente

- Ignorando a compatibilidade do material (Por exemplo, Contaminação por zinco)

- Com vista para os impactos do peso da placa na cinemática do triturador

A seleção estratégica paga dividendos

MasterizaçãoSeleção da placa da mandíbula Requer entender seu material, Tipo de máquina (como modelos C6X), e metas operacionais. Combina este guia com manutenção preventiva regular para alcançar 18-24 Mês prateleira vida útil mesmo em condições exigentes. Lembrar: A placa ideal hoje pode diferir amanhã – reavaliar as seleções com grandes mudanças materiais.

Sede Escritório

Whatsapp:+8615225176731

E-mail: [email protected]

Endereço: Não. 1688, Gaoke East Road, Novo distrito de Pudong, Xangai, China.

Local na rede Internet: https://www.mill-sbm.com/