Электронная почта: [email protected]

Зачем правильное обслуживание дробилки имеет значение?

Знаешь что? Я видел все это - от дробик, которые проходят как часовые на протяжении десятилетий до тех, кто ломается каждые несколько месяцев. Разница? It always comes down to maintenance. Proper jaw crusher maintenance isn’t just about keeping your machine running; it’s about maximizing your return on investment and ensuring your operation stays profitable. Jaw crushers are the workhorses of the mining and construction industry, handling everything from granite and basalt to concrete and asphalt. These powerful machines endure tremendous stress, crushing thousands of tons of material daily. Without proper care, even the most robust jaw crusher will suffer premature wear, unexpected breakdowns, and costly downtime.

Let me share what I’ve learned over the years about keeping these machines running at peak performance. Whether you’re managing a small quarry or a large mining operation, these maintenance practices will save you time, деньги, and headaches down the road.

Understanding Your Jaw Crusher Components

Before diving into maintenance procedures, it’s crucial to understand the key components that require regular attention. Your jaw crusher consists of several critical parts, each with its own maintenance requirements and replacement schedules.

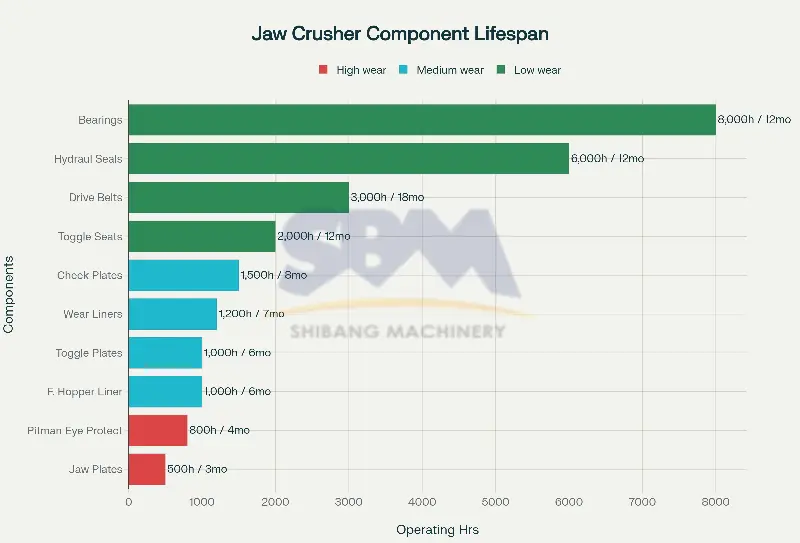

Thejaw plates (also called jaw dies) are your primary wear components, directly contacting and crushing the material. These manganese steel plates work-harden under impact, but they’ll need replacement every 400-500 operating hours for standard applications, or even more frequently when processing extremely hard materials like quartzite.

Toggle plates serve as the crusher’s safety mechanism, designed to break under excessive load to protect more expensive components. They typically last 1,000 hours or about six months under normal conditions.

Thepitman (moving jaw assembly) contains critical bearings that require regular lubrication and monitoring.

Don’t overlook theщеки пластины иwear liners – these protective elements prevent damage to the main frame and should be inspected weekly for excessive wear that could expose more expensive structural components.

Daily Maintenance: Your First Line of Defense

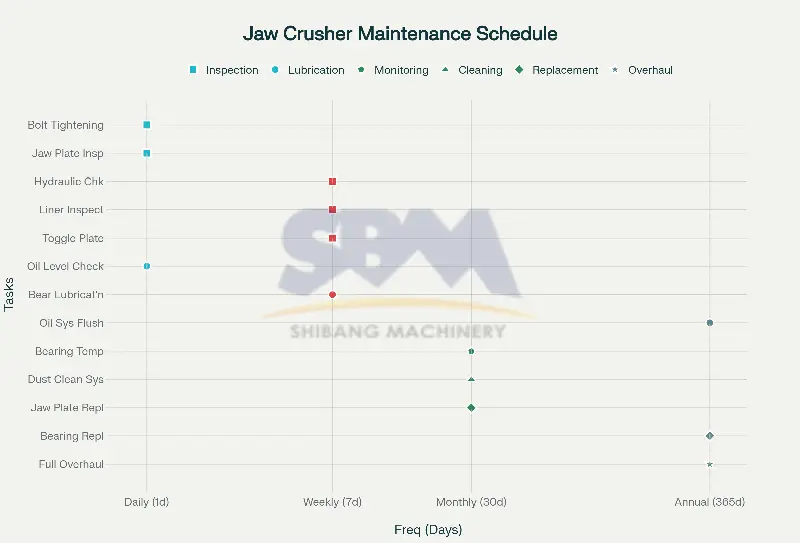

Starting each day with a thorough inspection routine is absolutely critical. I can’t stress this enough – daily maintenance prevents 20-30% of unplanned downtime and catches problems before they become expensive repairs.

Pre-Shift Inspection Checklist

Begin every shift with a comprehensive walk-around inspection. Look for any obvious signs of damage, loose components, or unusual wear patterns. Check the dump bridge for tire hazards and inspect the feed hopper to ensure proper material flow.

Lubrication system checks are non-negotiable. Verify that your automatic greaser system has adequate grease reserves and is functioning properly. If you’re running an oil lubrication system, start it up before the crusher to ensure proper flow and pressure. Trust me, bearing failures from inadequate lubrication are among the most expensive repairs you’ll face.

Jaw plate inspection should be part of your daily routine. Look for uneven wear patterns, cracks, or loose bolts. The jaw plates should maintain proper gap settings, and any signs of metal-to-metal contact indicate immediate attention is needed.

Bolt and fastener checks might seem tedious, but loose bolts cause vibration issues that can cascade into major problems. The constant vibration during operation naturally loosens connections, so daily torque checks on critical bolts prevent catastrophic failures.

Operational Monitoring

During startup, pay close attention to the amperage draw. Unusual current consumption often indicates bearing problems or motor issues before they become obvious through other symptoms. Document these readings in your maintenance log – trending data helps predict component failures.

Monitor the coast-down time daily. If your crusher typically takes five minutes to stop after shutdown but suddenly stops in three minutes, you likely have bearing problems developing. This simple observation can save thousands in repair costs.

Listen for unusual noises and feel for excessive vibration. Your jaw crusher should run smoothly with consistent sound patterns. Any changes in these characteristics warrant immediate investigation.

Еженедельные и ежемесячные задачи по техническому обслуживанию

Weekly maintenance involves more detailed inspections and servicing that daily checks can’t cover thoroughly. This is where you’ll catch developing problems before they cause unexpected shutdowns.

Weekly Inspection Protocol

Toggle plate and tension rod inspection requires careful attention. Check the condition of toggle plates for cracks or unusual wear patterns. These components transfer the crushing force and protect your crusher from overload damage. Adjust tension as needed according to manufacturer specifications.

Wear liner assessment should be thorough. Replace liners when thickness falls below manufacturer specifications – typically when they’ve lost 10-15% of their original thickness. Don’t wait until they’re completely worn through, as this can damage the main frame.

Hydraulic system maintenance includes checking fluid levels, inspecting for leaks, and testing system pressure. Low hydraulic pressure or fluid contamination can cause adjustment mechanism failures and safety system malfunctions.

Monthly Deep Maintenance

Monthly maintenance involves more comprehensive tasks that require equipment downtime but prevent major failures.

Bearing temperature monitoring becomes crucial during monthly inspections. Use infrared thermometers to check bearing temperatures during operation. Temperatures above 60°C (140°F) indicate potential lubrication problems or bearing wear.

Dust collection system cleaning prevents environmental issues and maintains proper airflow around the crusher. Accumulated dust can cause overheating and reduce component life significantly.

Amperage logging and analysis helps identify trends that predict component failures. Compare current readings to your baseline data to spot developing problems before they cause breakdowns.

Смазка: The Lifeblood of Your Crusher

Proper lubrication is absolutely critical for jaw crusher longevity. I’ve seen more crushers fail from lubrication problems than any other single cause.

Understanding Lubrication Requirements

Современные челюстные дробилки typically use either centralized automatic lubrication systems or manual greasing points. Automatic lubrication systems eliminate human error and ensure consistent lubricant distribution to all critical points.

The baseline guideline is to replenish grease every 8 hours of operation, though this varies based on your crusher model and operating conditions. Heavy-duty applications or dusty environments may require more frequent lubrication.

Grease quality is just as important as quantity. Use high-temperature grease with extreme pressure (EP) additives specifically designed for crusher applications. Standard automotive greases won’t withstand the extreme conditions in your crusher.

Lubrication Best Practices

Over-greasing is just as harmful as under-greasing. Excessive grease damages seals and attracts dust and contaminants. Follow manufacturer specifications exactly – more isn’t always better.

Watch forcontamination indicators during inspections. Discolored or gritty grease indicates contamination and requires immediate flushing and replacement. Metal particles in used grease samples can predict component wear before failures occur.

In cold environments, grease stiffening can impede flow through centralized systems. Use winter-grade formulations and consider heating systems for extreme conditions.

Документация of grease types, application dates, and consumption rates creates valuable maintenance history for trend analysis. Partner with lubricant suppliers to ensure you’re using OEM-approved products tailored to your specific crusher model.

Jaw Plate Management and Replacement

Jaw plates are your biggest consumable expense, but proper management can significantly extend their life and reduce costs.

Wear Pattern Analysis

Uneven wear often indicates feeding problems or improper settings. Material should feed evenly across the full width of the crusher opening, as close to center as possible. Top-heavy wear suggests improper feed distribution, while bottom wear might indicate discharge setting problems.

Flip and rotation strategies can double jaw plate life in many applications. Many crushers use identical jaw plates for both fixed and moving positions. Flipping plates so the bottom becomes the top, or swapping positions between fixed and moving jaws, maximizes material contact area utilization.

Plan jaw plate changes for every 400-500 operating hours under normal conditions, или 200 hours for extremely hard materials. Don’t wait until plates are completely worn – this reduces crushing efficiency and increases energy consumption.

Replacement Procedures

Safety first – always lock out and tag out equipment before beginning jaw plate replacement. These components are extremely heavy and require proper lifting equipment rated for their weight.

Proper installation is crucial for maximum life. Ensure jaw plates are correctly aligned and bolted to specified torque settings. Misaligned plates cause uneven wear and can damage the main frame.

Consider installing multiple jaw plate segments in large crushers. This allows you to replace only the most worn sections, reducing downtime and material costs.

Troubleshooting Common Problems

Even with excellent maintenance, problems occasionally arise. Quick diagnosis and resolution minimize downtime and prevent secondary damage.

Electrical and Startup Issues

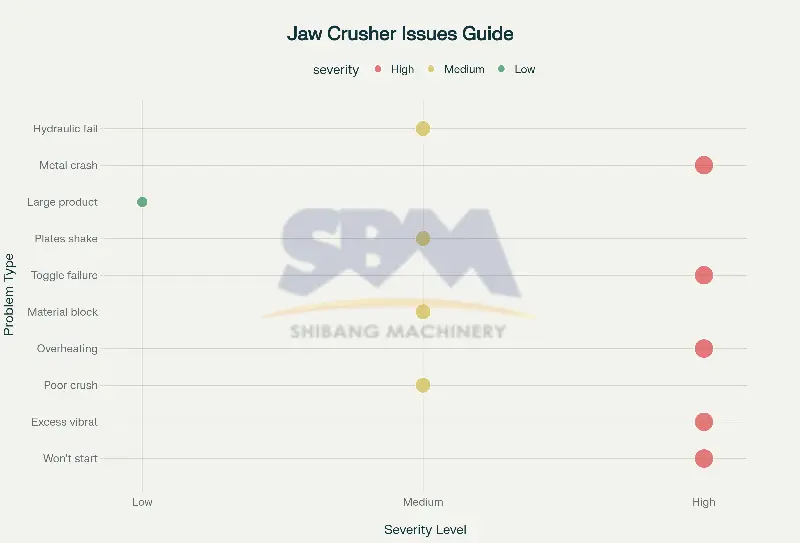

Crusher won’t start problems usually trace to electrical issues. Check power supply stability, inspect fuses and circuit breakers, and verify safety interlocks aren’t activated. Don’t overlook simple issues like emergency stops that haven’t been reset.

High amperage draw during startup often indicates bearing problems or motor issues. Monitor starting amperage and compare to normal values. Gradual increases suggest developing bearing wear, while sudden changes indicate immediate problems.

Mechanical Problems

Excessive vibration and noise typically result from loose bolts, worn bearings, or imbalanced components. Start with bolt checks – loose fasteners cause vibration that can cascade into more serious problems. Worn flywheels or eccentric shafts create imbalance requiring immediate attention.

Jaw plates shaking with metallic crashing sounds indicates loose jaw plate bolts or improper gap settings. Stop the crusher immediately and check all jaw plate fasteners. Retighten to specification or replace damaged bolts.

Toggle plate failure often results from excessive spring pressure or misalignment. Adjust spring tension according to manufacturer specifications and ensure toggle plates seat properly in their supports.

Performance Issues

Poor crushing performance usually indicates worn jaw plates, incorrect settings, or improper feeding. Check jaw plate condition and discharge opening settings first, then evaluate feed characteristics and distribution.

Material blockages typically result from oversized feed material or sticky conditions. Maintain proper feed sizing – maximum feed should be 80% of crusher opening width. Use metal detectors or manual inspection to prevent uncrushable objects from entering the crushing chamber.

Preventive Maintenance Scheduling

A systematic approach to preventive maintenance maximizes equipment life while minimizing unexpected downtime.

Creating Your Maintenance Program

Document everything in detailed maintenance logs. Track component replacement dates, operating hours, performance metrics, and problem history. This data enables predictive maintenance and helps optimize replacement intervals.

Seasonal maintenance should include complete crusher overhaul with detailed inspection of all systems. Replace major wear components, flush lubrication systems, and calibrate control systems before heavy production periods.

Staff training is crucial for maintenance program success. Ensure operators understand their daily inspection responsibilities and can recognize early warning signs of developing problems.

Maintenance Scheduling Tools

Использоватьoperating hours rather than calendar time for most maintenance intervals. Crushers operating 16 hours daily require more frequent service than those running eight hours daily, regardless of calendar time.

Condition-based maintenance uses actual component condition rather than fixed schedules for replacement decisions. Monitor wear rates, vibration levels, and temperature trends to optimize replacement timing.

Implementpredictive maintenance technologies where cost-effective. Vibration monitoring, oil analysis, and thermal imaging can predict failures before they occur.

Safety Considerations During Maintenance

Safety must be your top priority during all maintenance activities. Щековые дробилки are powerful machines that demand respect and proper safety procedures.

Процедуры блокировки/маркировки

Always de-energize and lock out equipment before performing any maintenance. Multiple energy sources (электрический, гидравлический, pneumatic) require individual lockout procedures. Never rely on someone else’s lockout – verify zero energy state yourself.

Confined space considerations apply when entering crusher chambers or chutes. Follow proper atmospheric testing and ventilation procedures. Ensure adequate lighting and communication with outside personnel.

Personal Protective Equipment

Heavy lifting operations during component replacement require proper equipment rated for the loads involved. Jaw plates and other wear components are extremely heavy and can cause serious injury if not handled properly.

Eye and respiratory protection are essential when working around crushers. Dust exposure and flying particles present serious health hazards. Use appropriate filters and protective equipment for your specific application.

Emergency Procedures

Emergency shutdown procedures must be clearly understood by all personnel. Ensure emergency stops are easily accessible and regularly tested. Develop evacuation plans for serious emergencies and conduct regular drills.

First aid preparation should include training for personnel working around heavy machinery. Maintain properly stocked first aid stations and ensure communication systems work reliably in all areas.

Performance Optimization Strategies

Beyond basic maintenance, several strategies can optimize jaw crusher performance and extend component life.

Feed Optimization

Choke feeding maximizes crusher efficiency by maintaining a full crushing chamber. Keep the chamber at least 80% full during operation to optimize material flow and particle shape. This technique also helps protect jaw plates through stone-on-stone crushing action.

Feed sizing should follow the 80% rule – maximum feed size should be 80% of crusher opening width. For a 30-inch opening, limit feed to 24-inch maximum size to prevent bridging and jamming.

Pre-screening removes fines and oversized material before crushing. Fines reduction improves crusher efficiency and throughput, while oversize removal prevents jamming and damage.

Operating Parameters

Discharge opening adjustment directly affects product size and crusher throughput. Smaller settings produce finer products but reduce capacity and increase power consumption. Find the optimal balance for your application requirements.

Feed rate consistency prevents overloading and underloading cycles that increase wear and reduce efficiency. Use variable frequency drives to maintain consistent crusher loading regardless of feed variations.

Speed optimization affects crushing efficiency and power consumption. Higher speeds increase crushing cycles but may increase wear and power draw if not properly balanced with other parameters.

Cost Management and ROI

Effective maintenance programs require balancing costs with benefits to maximize return on investment.

Maintenance Cost Analysis

Preventive maintenance costs typically represent 15-20% of total maintenance expenses but prevent 60-80% of potential failures. This investment pays significant dividends through reduced downtime and emergency repair costs.

Wear parts inventory management balances carrying costs against availability requirements. Maintain adequate stock of critical wear components without excessive capital tie-up in slow-moving parts.

Labor cost optimization through proper training and efficient procedures reduces maintenance time and costs. Skilled technicians complete tasks faster and with better quality than untrained personnel.

Performance Metrics

Overall equipment effectiveness (OEE) measures the combined impact of availability, performance, and quality. Track these metrics to identify improvement opportunities and justify maintenance investments.

Cost per ton metrics help evaluate maintenance program effectiveness. Include all costs – labor, части, время простоя, and energy – to get accurate performance measures.

Component life tracking enables optimization of replacement intervals and identification of factors affecting wear rates. Use this data to negotiate better prices with suppliers and optimize inventory levels.

Environmental and Regulatory Compliance

Modern mining operations must address environmental concerns and regulatory requirements in their maintenance programs.

Dust Control Systems

Regular dust suppression system maintenance prevents environmental violations and protects worker health. Check water flow rates, nozzle condition, and coverage patterns during weekly inspections.

Filter system maintenance in enclosed crusher installations requires regular attention to prevent system overload and ensure proper dust capture. Replace filters according to pressure drop measurements rather than fixed schedules.

Fluid Management

Hydraulic fluid containment prevents environmental contamination from system leaks. Inspect containment systems regularly and maintain spill response equipment. Use biodegradable fluids where possible to reduce environmental impact.

Used oil and grease disposal must follow environmental regulations. Partner with certified disposal companies and maintain proper documentation for regulatory compliance.

Technology Integration and Future Trends

Modern maintenance programs increasingly incorporate technology to improve efficiency and effectiveness.

Monitoring Systems

Real-time condition monitoring uses sensors to track vibration, температура, and other parameters continuously. These systems provide early warning of developing problems and enable condition-based maintenance.

Remote monitoring capabilities allow maintenance personnel to track crusher performance from central locations. This technology is particularly valuable for remote operations where personnel visits are expensive and difficult to schedule.

Automation Benefits

Automated lubrication systems eliminate human error and ensure consistent lubricant application. Modern systems include monitoring capabilities that alert operators to system malfunctions or low lubricant levels.

Performance optimization software can automatically adjust crusher parameters based on feed characteristics and production requirements. These systems reduce operator workload while maintaining optimal performance.

Building Your Maintenance Excellence Program

Successful jaw crusher maintenance isn’t just about following checklists – it’s about developing a culture of equipment care that extends throughout your organization. The strategies I’ve shared here represent decades of field experience and proven practices from successful operations worldwide.

Remember thatПоследовательность является ключевым. Daily inspections might seem routine, but they’re your best defense against expensive failures. Don’t skip them when production pressures mount – that’s exactly when problems are most likely to develop.

Invest in your people through proper training and clear procedures. The best maintenance program on paper means nothing if your team doesn’t understand or follow it. Create an environment where reporting potential problems is rewarded, not punished.

Document everything and use that data to continuously improve your program. Track component life, failure modes, and maintenance costs to identify opportunities for optimization. What works in one application might not work in another, so adapt these guidelines to your specific conditions.

Окончательно, remember thatpreventive maintenance is always cheaper than reactive maintenance. The hour you spend on daily inspections can save weeks of downtime later. The dollars invested in quality wear parts and proper lubrication pay dividends through extended component life and improved productivity.

Your jaw crusher is a significant capital investment that, with proper care, can provide decades of reliable service. Follow these maintenance practices consistently, adapt them to your specific conditions, and you’ll maximize both equipment life and profitability. После всего, in our business, downtime costs money – but proper maintenance makes money.

By implementing these comprehensive maintenance strategies, you’re not just maintaining equipment – you’re protecting your investment, ensuring worker safety, and building a foundation for long-term operational success. That’s what separates good operations from great ones, and it’s what keeps your jaw crusher running strong year after year.

Главный офис

WhatsApp:+8615225176731

Электронная почта: [email protected]

Адрес: Нет. 1688, Гаоке Ист Роуд, Новый район Пудун, Шанхай, Китай.

Веб-сайт: https://www.mill-sbm.com/