อีเมล: [email protected]

ขายเครื่องบดคอนกรีตเคลื่อนที่ | เพิ่มประสิทธิภาพการบด

ในสาขาการก่อสร้างและการขุดที่วุ่นวายในปัจจุบัน, การมีความยืดหยุ่นและการทำงานอย่างมีประสิทธิภาพเป็นสิ่งสำคัญที่สุด. ช่วงเวลาที่บริษัทต่างๆ ต้องพึ่งพาโรงงานขนาดใหญ่เพื่อบดคอนกรีตจำนวนมาก, หิน, และแร่ก็จบลงแล้ว. เดอะเครื่องบดคอนกรีตแบบเคลื่อนที่ มีขนาดเล็ก, แข็งแกร่ง, และเครื่องประหยัดต้นทุนที่ผลิตได้สูงที่ไซต์งาน.

เครื่องบดแบบเคลื่อนที่สะดวกมาก—ไม่ต้องใช้ฐานราก, ใช้เวลาในการตั้งค่าน้อยลง, และสามารถเคลื่อนย้ายได้ง่าย. ทำให้เป็นตัวเลือกยอดนิยมสำหรับผู้รับเหมา, คนงานเหมือง, และผู้รีไซเคิล. คู่มือนี้จะช่วยให้คุณเข้าใจทุกสิ่งที่จำเป็นในการเลือกเครื่องบดที่ดีที่สุดสำหรับบริษัทของคุณ, รวมถึงวิธีการทำงานด้วย, มันถูกสร้างขึ้นมาอย่างไร, มีค่าใช้จ่ายเท่าไรในการวิ่ง, และรุ่นใดที่เป็นตัวเลือกที่ดีที่สุดในตลาดปัจจุบัน.

เครื่องบดคอนกรีตแบบเคลื่อนที่คืออะไร?

อันเครื่องบดคอนกรีตแบบเคลื่อนที่ เป็นเครื่องเคลื่อนย้ายที่ผสมผสานการให้อาหาร, บดขยี้, การเรียงลำดับ, และเคลื่อนย้ายวัสดุทั้งหมดได้ในเฟรมเดียว. สร้างขึ้นเพื่อประมวลผลวัสดุที่พบในไซต์งานอย่างรวดเร็ว เช่น คอนกรีตที่แตกหัก, ยางมะตอย, หินธรรมชาติ, และของเหลือจากการก่อสร้าง.

แตกต่างจากสายบดแบบตายตัวที่ต้องติดตั้งแบบถาวรและลงทุนมากขึ้น, เครื่องบดแบบเคลื่อนที่สามารถเคลื่อนย้ายระหว่างไซต์งานได้โดยใช้รถบรรทุกหรือรถพ่วง. เครื่องจักรเช่น SBMโรงงานบดแบบพกพา K3 ซีรี่ส์ และเครื่องบดแบบเคลื่อนที่แบบติดตาม ถูกสร้างขึ้นเพื่อเพิ่มการผลิตในขณะที่ลดการหยุดทำงาน.

เหตุใดผู้รับเหมาและเจ้าของโรงงานจึงชอบรถบดแบบเคลื่อนที่

มีเหตุผลหลายประการที่ทำให้เครื่องบดแบบพกพากลายเป็นทางออกในการก่อสร้างและการขุด:

- ติดตั้งรวดเร็ว — พร้อมที่จะทำลายภายในไม่กี่ชั่วโมง, ไม่ใช่วัน.

- ลดต้นทุนการขนส่งและการจัดการวัสดุ.

- สามารถแปรรูปวัตถุดิบที่หลากหลายในสถานที่ได้.

- ลดความต้องการโครงสร้างพื้นฐานแบบคงที่.

- การดำเนินงานที่เป็นมิตรต่อสิ่งแวดล้อมโดยมีฝุ่นและเสียงรบกวนลดลง.

เดอะเครื่องบดคอนกรีตแบบเคลื่อนที่ ช่วยเพิ่มประสิทธิภาพต้นทุนโครงการโดยการลดค่าใช้จ่ายในการขนส่ง, ช่วยให้สามารถผลิตได้อย่างต่อเนื่องโดยตรงจากแหล่งวัตถุดิบ.

ประโยชน์หลักของเครื่องบดคอนกรีตแบบเคลื่อนที่

มีความยืดหยุ่นสูง

เครื่องจักรเหล่านี้สามารถใช้ในการรื้อถอนเมืองได้, สร้างถนน, วัสดุแปรรูปเช่นกรวด, หรือการขุดหลุมเปิด—โดยพื้นฐานแล้วเป็นสถานที่ใดก็ตามที่จำเป็นต้องบด.

การเปลี่ยนแปลงอย่างรวดเร็วระหว่างไซต์

รุ่นใหม่กว่าเช่นซีรีส์ SBM NK มีชิ้นส่วนที่สามารถถอดออกได้ง่ายและมีขาไฮดรอลิก, จึงทำงานได้โดยไม่ต้องใช้ฐานคอนกรีต. คุณไม่จำเป็นต้องแยกเครื่องเพื่อย้ายจากที่หนึ่งไปอีกที่หนึ่ง.

ผลตอบแทนการลงทุนที่ดีขึ้น

การมีเครื่องบดที่ไซต์งานหมายถึงการทำงานที่รวดเร็วขึ้นและค่าแรงที่ลดลง, ขนส่ง, และเชื้อเพลิง. ความยืดหยุ่นนี้ช่วยให้คุณทำเงินได้มากขึ้นเมื่อเวลาผ่านไป.

การใช้งานของเครื่องบดคอนกรีตแบบเคลื่อนที่

| พื้นที่ใช้งาน | คำอธิบาย | ตัวอย่างวัสดุ |

|---|---|---|

| การรีไซเคิลขยะก่อสร้าง | เปลี่ยนคอนกรีตที่รื้อถอนให้เป็นมวลรวมที่นำกลับมาใช้ใหม่ได้ | คอนกรีตเสริมเหล็ก, อิฐ, ยางมะตอย |

| ปฏิบัติการเหมืองหิน | การบดหินหลักและรอง | หินแกรนิต, หินปูน, หินบะซอลต์ |

| การทำเหมืองแร่และการแปรรูปแร่ | บดแร่ก่อนบด | แร่เหล็ก, แร่ทองแดง, หินที่มีทองคำ |

| การพัฒนาโครงสร้างพื้นฐาน | การผลิตฐานถนนและวัสดุเกรดล่างในสถานที่ | กรวด, คอนกรีตรีเคลม |

ไม่ว่าจะทำงานในสภาพแวดล้อมในเมืองที่คับคั่งหรือไซต์เหมืองหินห่างไกล, เครื่องบดคอนกรีตแบบเคลื่อนที่มีทั้งกำลังและความสะดวกในการพกพา.

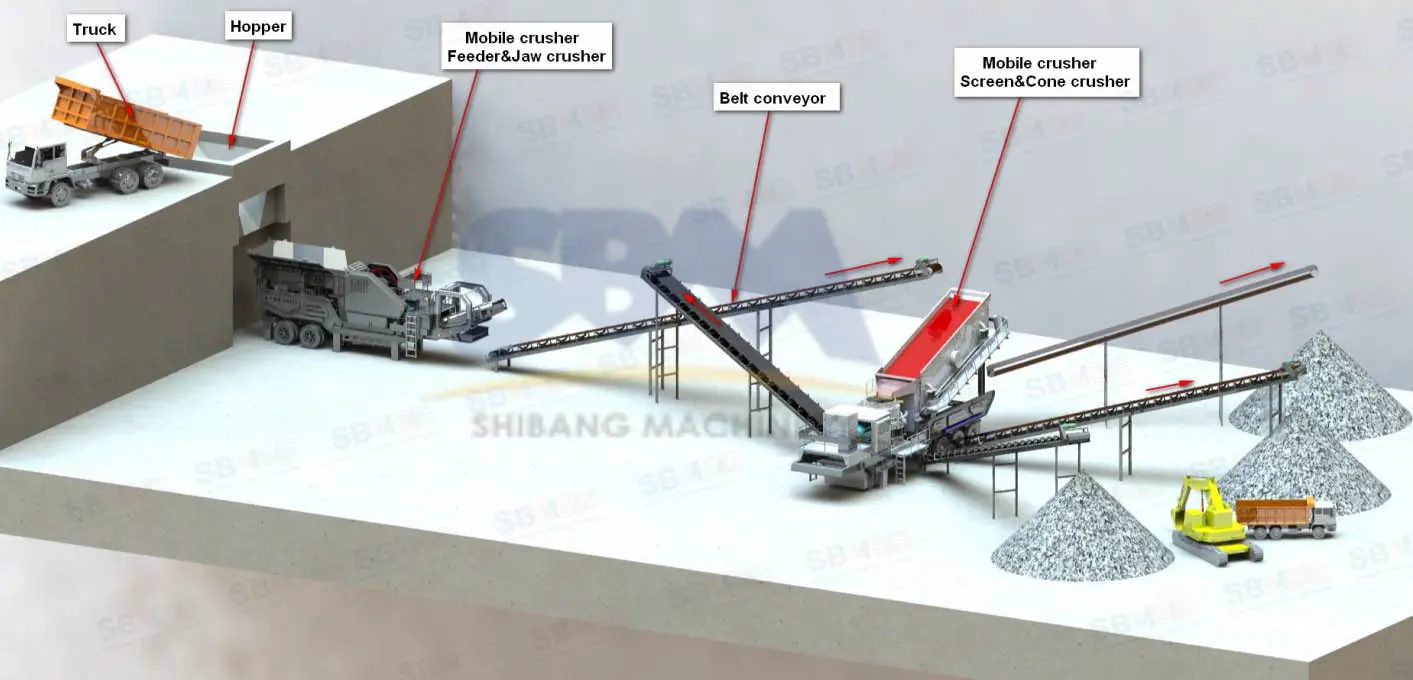

หลักการทำงานของเครื่องบดคอนกรีตแบบเคลื่อนที่

แนวคิดนี้เรียบง่ายแต่มีประสิทธิภาพมาก. วัสดุเช่นคอนกรีตหรือหินจะถูกป้อนเข้าไปในเครื่องบดโดยใช้ เครื่องป้อนแบบสั่น. แล้ว, วัสดุถูกบดขยี้ด้วย a บดกราม, หนึ่ง เครื่องบดอัด, หรือก กรวยบด, ขึ้นอยู่กับรุ่น.

หลังจากการบดขั้นตอนแรก, วัสดุจะผ่านตะแกรงสั่นเพื่อจัดเรียงตามขนาด. วัสดุใดก็ตามที่มีขนาดใหญ่เกินไปจะต้องกลับไปบดอีกรอบจนกว่าจะได้ขนาดที่เหมาะสม.

เครื่องบดมือถือที่ทันสมัย, ชอบ ซีรีส์ SBM K3, ใช้ระบบวงปิด, ซึ่งทำให้ขนาดผลิตภัณฑ์คงที่และช่วยให้สามารถแปรรูปวัสดุได้มากขึ้น.

เครื่องบดคอนกรีตเคลื่อนที่ประเภทต่างๆ

ขึ้นอยู่กับประเภทวัสดุและผลลัพธ์ที่ต้องการ, มีเครื่องบดแบบเคลื่อนที่ได้หลายประเภท:

| พิมพ์ | ฟังก์ชั่นหลัก | เหมาะสำหรับ | ตัวอย่างโมเดล |

|---|---|---|---|

| เครื่องบดมือถือแบบกราม | การบดหยาบ | วัสดุแข็ง | SBM Jawmax ซีรีส์ |

| เครื่องบดแบบเคลื่อนที่แบบกระแทก | การบดและการรีไซเคิลขั้นที่สอง | คอนกรีต, ยางมะตอย | SBM REMAX หรือ SMR Series |

| เครื่องบดมือถือแบบกรวย | การบดละเอียดถึงปานกลาง | หินบะซอลต์, หินแกรนิต | ซีรีส์ SBM K3 พร้อมโมดูล H300 |

| เครื่องบดแบบเคลื่อนที่รวมหลายหน่วย | การบดและการคัดกรองแบบรวม | การใช้งานที่ซับซ้อน | SBM K3T150-4 หรือ K3YC-200T |

แต่ละหมวดหมู่มีข้อได้เปรียบในตัวเอง นั่นคือชุดขากรรไกรเพื่อความทนทาน, หน่วยกระแทกสำหรับการควบคุมรูปร่าง, หน่วยกรวยสำหรับการผลิตมวลรวมที่ละเอียด.

การเลือกรุ่นที่เหมาะสมตามความจุ

เมื่อเลือกเครื่องบดคอนกรีตแบบเคลื่อนที่ของคุณ, ความจุ มักเป็นปัจจัยแรกในการตัดสินใจ. มาดูการกำหนดค่าทั่วไปกัน (ขึ้นอยู่กับข้อมูลทางเทคนิคของ SBM):

| แบบอย่าง | ขนาดการให้อาหาร (มม) | ความจุ (ไทย) | แอปพลิเคชัน |

|---|---|---|---|

| K3T100-4 | 0–450 | 100–150 | สถานที่ก่อสร้างขนาดเล็ก-กลาง |

| K3YC-150T | ≤530 | 150–200 | การผลิตมวลรวมทั่วไป |

| K3YC-300T | ≤630 | 250–450 | การทำเหมืองแร่และเหมืองหินหนัก |

| NK300 | ≤720 | 300–500 | การบดแบบหลายขั้นตอนขนาดใหญ่ |

ตามกฎทั่วไป: ยิ่งขนาดฟีดและความต้องการกำลังการผลิตมากขึ้นเท่านั้น, ยิ่งคุณต้องการพลังขับเคลื่อนและความแข็งแกร่งของแชสซีมากขึ้นเท่านั้น.

เครื่องบดแบบพกพากับเครื่องบดแบบอยู่กับที่

| คุณสมบัติ | เครื่องบดคอนกรีตเคลื่อนที่ | โรงงานบดนิ่ง |

|---|---|---|

| เวลาตั้งค่า | 1–2 วัน | 10–30 วัน |

| การย้ายถิ่นฐาน | ง่าย, พร้อมขนส่ง | ถาวร |

| พื้นฐาน | ไม่จำเป็นต้องใช้คอนกรีต | จำเป็น |

| ประสิทธิภาพต้นทุน | ต้นทุนการดำเนินงานที่ต่ำกว่า | ค่าติดตั้งที่สูงขึ้น |

| ปริมาณการผลิต | ขึ้นไป 500 ไทย | ขึ้นไป 2000 ไทย |

หากความคล่องตัวและความยืดหยุ่นคือสิ่งที่คุณให้ความสำคัญเป็นอันดับแรก, เครื่องบดแบบเคลื่อนที่ชนะมือ. แต่ถ้าการดำเนินการของคุณจัดการได้สูงมาก, ปริมาณการผลิตที่สม่ำเสมอ, ตัวเลือกแบบอยู่กับที่อาจจะยังคุ้มค่าที่จะพิจารณา.

ข้อดีด้านสิ่งแวดล้อมและความปลอดภัย

การดูแลสิ่งแวดล้อมมีความสำคัญมากขึ้นกว่าที่เคย. บริษัทอย่าง SBM ได้ทำเครื่องบดคอนกรีตแบบเคลื่อนที่ ด้วยคุณสมบัติสีเขียวเช่น:

- ระบบป้องกันฝุ่นแบบปิด.

- ฉนวนกันเสียงเพื่อการทำงานที่เงียบยิ่งขึ้น.

- ผ้าคลุมผ้าใบสำหรับกักเก็บฝุ่น.

- โหมดพลังงานที่ปรับได้เพื่อลดการปล่อยมลพิษ.

สิ่งเหล่านี้ทำให้มั่นใจได้ว่าโรงงานของคุณตรงตามมาตรฐานด้านสิ่งแวดล้อมที่เข้มงวดโดยไม่กระทบต่อประสิทธิภาพ.

การซ่อมบำรุง & เคล็ดลับการมีอายุยืนยาว

การตรวจสอบเป็นประจำเป็นสิ่งสำคัญมากในการทำให้เครื่องบดแบบพกพาของคุณทำงานได้ดี. ทำตามขั้นตอนการบำรุงรักษาหลักเหล่านี้:

- ตรวจสอบชิ้นส่วนที่สึกหรอ เช่น แฮนด์บาร์, ตอร์ปิโด, และเข็มขัดทุกสัปดาห์.

- รักษาระบบไฮดรอลิกให้ปิดสนิทและสะอาด.

- เพิ่มน้ำมันและจาระบีทุกวันตามที่แนะนำ.

- ตรวจสอบเซ็นเซอร์และระบบควบคุมก่อนทุกกะ.

เครื่องบดแบบเคลื่อนที่ SBM ต้องการการบำรุงรักษาเพียงเล็กน้อยและมาพร้อมกับระบบควบคุมไฮดรอลิกอัจฉริยะ, การป้องกันการโอเวอร์โหลด, และคุณสมบัติการรีเซ็ตอัตโนมัติ.

ตัวอย่างโลกแห่งความเป็นจริง: กรณีศึกษาการก่อสร้าง SME

บริษัทก่อสร้างขนาดกลางใช้ SBM'sK3YC-200T เครื่องบดแบบเคลื่อนที่เพื่อประมวลผลเศษซากจากการรื้อถอนให้เป็นมวลรวมขนาด 0–32 มม. สำหรับฐานถนน.

- ระยะเวลาโครงการ: 6 เดือน

- ผลผลิต: 200 ไทย

- ลดต้นทุนการลาก: 40%

- ระยะเวลาคืนทุน: 8 เดือน

ความยืดหยุ่นของการประมวลผลนอกสถานที่ช่วยเพิ่มความสามารถในการทำกำไรที่วัดได้เมื่อเปรียบเทียบกับการบดแบบจ้างจากภายนอก.

ผลตอบแทนจากการลงทุน (ผลตอบแทนการลงทุน) ข้อควรพิจารณา

ROI สามารถคำนวณได้โดยใช้สูตร:

ตัวอย่าง:

หากคุณลงทุน $250,000 และบันทึก $20,000 รายเดือนในต้นทุนการขนส่งและการแปรรูป, ระยะเวลาคืนทุนของคุณคือมากกว่าหนึ่งปี. ยิ่งคุณดำเนินโครงการมากขึ้นต่อปี, ยิ่ง ROI ทบต้นเร็วขึ้นเท่าไร.

เครื่องบดคอนกรีตแบบเคลื่อนที่มอบ ROI ที่ดีที่สุดสำหรับธุรกิจที่ต้องการโซลูชันที่ปรับเปลี่ยนได้ทั่วทั้งไซต์งานหลายแห่ง.

วิธีเลือกเครื่องบดมือถือในอุดมคติของคุณ?

เมื่อเลือกยูนิต, พิจารณาปัจจัยสำคัญหกประการนี้:

- ความแข็งของวัสดุ – หินแกรนิตและ หินบะซอลต์ ต้องใช้กรวยหรือเครื่องบดกระแทก.

- เป้าหมายความจุ – จับคู่ผลลัพธ์ให้ตรงกับความต้องการประจำวันของคุณ (100–500 ตัน/ชม. โดยทั่วไป).

- ความคล่องตัว – ประเภทแทร็กสำหรับภูมิประเทศที่ขรุขระ, ประเภทยางสำหรับถนน.

- แหล่งพลังงาน – ดีเซล-ไฮดรอลิกหรือไฟฟ้าขึ้นอยู่กับงานของคุณ.

- เงื่อนไขของไซต์ – ตรวจสอบให้แน่ใจว่ามีพื้นที่เพียงพอสำหรับรถตัก, สายพานลำเลียง, และรถบรรทุก.

- บริการหลังการขาย – เลือกผู้ผลิตที่มีชิ้นส่วนในท้องถิ่นและการสนับสนุน.

SBM โดดเด่นด้วยการให้การสนับสนุนตลอดอายุการใช้งานอย่างสมบูรณ์, รวมถึงการฝึกอบรม, อะไหล่, และการบำรุงรักษาภาคสนามทั่วโลก.

ปัจจัยด้านราคาและการวิเคราะห์ต้นทุน

| องค์ประกอบต้นทุน | คำอธิบาย | ผลกระทบต่อราคา |

|---|---|---|

| ความสามารถในการบด | ความจุที่สูงขึ้น = ส่วนประกอบที่ใหญ่ขึ้น | +15–25% |

| ประเภทการเคลื่อนไหว | แบบติดตั้งบนรางมีราคาแพงกว่าแบบยาง | +10–20% |

| ประเภทคั้น | ผลกระทบ > กราม > กรวย | ตัวแปร |

| ยี่ห้อ & ประเทศต้นกำเนิด | รุ่นที่นำเข้าจะมีป้ายราคาที่สูงกว่า | 15–ความแปรผัน 30% |

เครื่องบดคอนกรีตแบบเคลื่อนที่ส่วนใหญ่มีตั้งแต่$150,000 ถึง $500,000, ขึ้นอยู่กับตัวเลือกและคุณสมบัติ.

แนวโน้มในอนาคตของการบดแบบเคลื่อนที่

เหตุใดจึงเลือกเครื่องบดคอนกรีตแบบเคลื่อนที่ SBM

SBM มีประสบการณ์หลายทศวรรษในการออกแบบและผลิตระบบบดขั้นสูงสำหรับภาคการก่อสร้างและเหมืองแร่. จุดขายที่สำคัญ ได้แก่:

- ขนาดอินพุตสูงสุด720 มม; ความจุจาก30–450 ตัน/ชม.

- การออกแบบยานพาหนะแบบโมดูลาร์เพื่อการขนส่งที่รวดเร็ว.

- ขารองรับไฮดรอลิกเพื่อการปรับใช้ที่รวดเร็ว.

- ระบบควบคุมเสียงและฝุ่น.

- ประวัติการทำงานและการบริการที่ครอบคลุมทั่วโลกที่ได้รับการพิสูจน์แล้ว.

สำหรับลูกค้าที่กำลังมองหาความสมดุลในอุดมคติของประสิทธิภาพการผลิต, พกพาสะดวก, และความน่าเชื่อถือ, เครื่องบดย่อย SBM K3 และ NK Series เป็นตัวแทนของโซลูชันระดับโลก.

บทสรุป: บดอย่างชาญฉลาด, ไม่ยาก

เดอะเครื่องบดคอนกรีตแบบเคลื่อนที่ ได้กลายเป็นเครื่องมือสำคัญสำหรับงานก่อสร้างและเหมืองแร่ในปัจจุบัน. มันช่วยประหยัดเวลา, ลดต้นทุน, และปรับปรุงประสิทธิภาพ—ทั้งหมดในขณะเดียวกันก็ช่วยให้บริษัทปฏิบัติตามกฎเกณฑ์ด้านสิ่งแวดล้อมที่เข้มงวดยิ่งขึ้น.

ไม่ว่าคุณจะต้องรีไซเคิลคอนกรีตในเมืองหรือบดหินแข็งในเหมือง, การมีเครื่องพกพาช่วยให้คุณทำงานต่อไปได้โดยไม่ต้องหยุด, ไม่ว่าโครงการของคุณจะอยู่ที่ไหน.

หากเป็นการประหยัดเวลา, เคลื่อนย้ายง่าย, และการทำกำไรมากขึ้นเป็นสิ่งสำคัญสำหรับคุณ, การซื้อเครื่องบดคอนกรีตแบบเคลื่อนที่อาจเป็นทางเลือกที่ดีที่สุดที่บริษัทของคุณเลือกในปีนี้.