E-mail: [email protected]

Các thành phần máy nghiền hàm chính được giải thích: Thiết kế, Chức năng & Sự chăm sóc

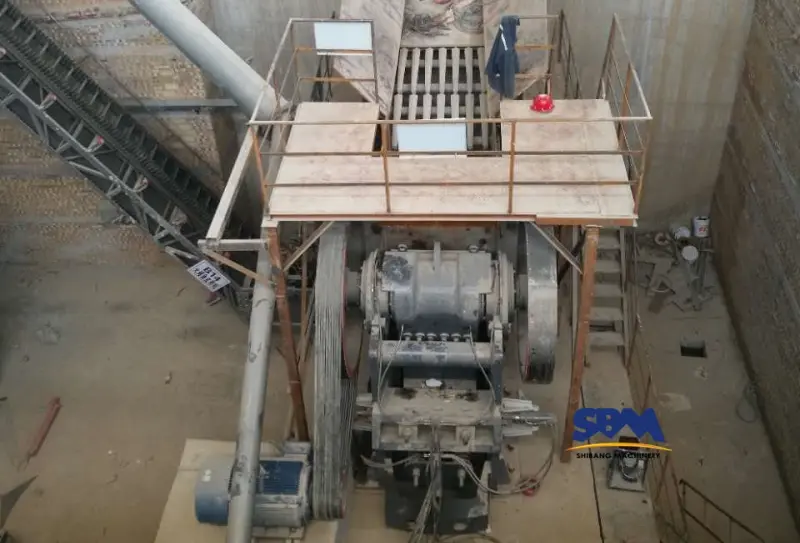

Các thành phần chính của máy nghiền hàm là gì? Từ mỏ đá ở Đức đến địa điểm khai thác mỏ ở Chile, máy nghiền hàm là xương sống của quá trình xử lý vật liệu. Nhưng điều gì làm cho những chiếc máy này hoạt động hiệu quả đến vậy? Hãy cùng khám phá cấu trúc của chúng thông qua các tình huống thực tế và phân tích xem mỗi thành phần góp phần tạo nên thành công vang dội như thế nào.

Công cụ của máy nghiền hàm: Tấm hàm cố định và di chuyển

Hình ảnh một mỏ đá granite ở Thụy Điển: Một máy nghiền hàm xử lý 500 tấn đá mỗi ngày. Cốt lõi của hoạt động này là hai tấm chắc chắn—má kẹp cố định và di động. Hàm cố định hoạt động như một cái đe, trong khi hàm di động có thể tung ra những cú đánh liên tục, giống như cái búa của thợ rèn.

Tại sao nó quan trọng:

- Tấm hàm cố định: Bắt vít chặt vào khung, nó chịu được tác động liên tục mà không bị uốn cong.

- Tấm hàm di chuyển: Gắn vào một cụm đu đưa, nó tạo ra lực nghiền thông qua chuyển động lệch tâm.

Cái nhìn sâu sắc về thế giới thực:

Một nhà thầu ở Texas đã giảm chi phí thay thế bằng 40% sau khi chuyển sang tấm hàm lồng vào nhau bằng hợp kim mangan tiên tiến. Để được hướng dẫn, xem của chúng tôilựa chọn tấm hàm danh sách kiểm tra.

Hậu trường: Những anh hùng thầm lặng

Trục lệch tâm – Bậc thầy chuyển động

Tại một mỏ vàng ở Nam Phi, trục lệch tâm bị hỏng sau khi ngừng hoạt động trong một thời gian 72 giờ. Thành phần thép cứng này chuyển chuyển động quay của động cơ thành chuyển động hình elip của hàm di động. Các tính năng chính:

- Được gia công chính xác để chống rung.

- Được hỗ trợ bởi vòng bi tang trống cho tải nặng.

Hack bảo trì:

Theo dõi nhiệt độ vòng bi hàng tuần. Sự tăng đột ngột thường báo hiệu sự bôi trơn không đủ hoặc sai lệch.

Tấm chuyển đổi – Lưới an toàn của máy nghiền

Khi một thanh thép lạc lọt vào máy nghiền ở nhà máy tái chế ở Anh, tấm chuyển đổi bị cố ý làm vỡ—tiết kiệm được 15.000 bảng Anh tiền thiệt hại có thể xảy ra. Phần da này:

- Hoạt động như một cầu chì cơ khí.

- Cho phép thiết lập lại nhanh chóng sau sự cố.

Thiết kế buồng nghiền: Nơi hình học đáp ứng hiệu quả

Máy nghiền hiện đại như C150 sử dụng thiết kế khoang dốc để chống trượt vật liệu. Các yếu tố ảnh hưởng đến hiệu suất buồng:

- Kích thước mở nguồn cấp dữ liệu (ví dụ., 1,400×1,200 mm trong các mô hình lớn).

- Góc Nip (lý tưởng là 22°-24° để nén tối ưu).

Trường hợp nghiên cứu:

Một nhà sản xuất tổng hợp của Canada đã tăng sản lượng lên 18% bằng cách trang bị thêm buồng của họ với các đường cong hàm. Khám phá các lựa chọn trong của chúng tôimáy nghiền hàm mới hướng dẫn so sánh.

Quy trình bảo trì từ các nhà khai thác toàn cầu

Kiểm tra độ mòn 3 điểm (Được thông qua tại các mỏ của Úc)

- Độ dày tấm hàm: Đo hàng tháng bằng máy đo siêu âm. Thay thế khi <60% gốc.

- Lớp lót bên: Kiểm tra các vết nứt trong quá trình thay đổi ca.

- Chuyển đổi căn chỉnh chỗ ngồi: Xác minh bằng mức laser hàng quý.

Chiến lược đã được chứng minh:

Mỏ đồng Zambian đã kéo dài tuổi thọ của lớp lót lên tới 30% sử dụng thao tác lật xoay—một kỹ thuật được trình bày chi tiết trongthay thế lót máy nghiền hàm hướng dẫn.

Khi nào cần gọi thời gian trên máy nghiền cũ

Dấu hiệu đã đến lúcmáy nghiền hàm mới:

- Sự cố vòng bi thường xuyên (>3/năm).

- Tiêu thụ năng lượng tăng 15% thông số kỹ thuật trên.

- Không có khả năng đáp ứng các tiêu chuẩn an toàn mới hơn (ví dụ., ISO 21873-2:2020).

Từng bước một: Cài đặt để thành công

Một công ty kỹ thuật của Đứccài đặt một máy nghiền hàm giao thức bao gồm:

- Khung cơ sở căn chỉnh bằng laser với dung sai ≤0,2mm/m.

- Bôi trơn trước vòng bi bằng mỡ tổng hợp.

- Kiểm tra mức độ rung khi chạy rỗng (<7mm/s RMS).

Điểm mấu chốt: Vận hành thông minh = Hiệu suất lâu dài

Hiểu các thành phần chính của máy nghiền hàm không chỉ là thuật ngữ kỹ thuật—mà còn là bảo vệ lợi nhuận. Bằng cách ghép nối mạnh mẽmẹo bảo trì cho máy nghiền hàm với những nâng cấp mang tính chiến lược, hoạt động giống như một nhà máy đá vôi của Malaysia đã đạt được 95% thời gian hoạt động.