Correo electrónico: [email protected]

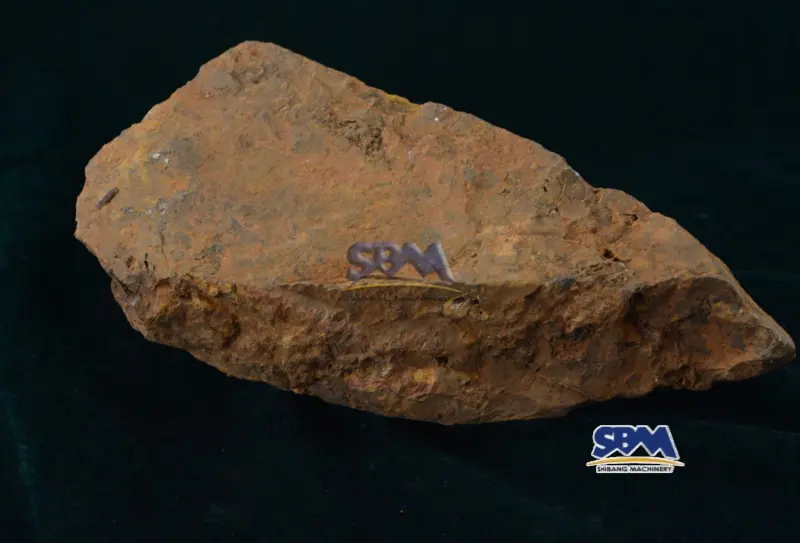

Trituradoras de mandíbula fija para triturador de mineral de hierro

En las industrias mineras y de procesamiento mineral, Crushers de la mandíbula fija are indispensable for efficiently breaking down hard materials like iron ore. Diseñado con una construcción robusta e ingeniería avanzada, these machines deliver high productivity while minimizing operational costs. This article explores their working principles, global applications, and practical tips for optimizing performance.

Estudios de casos globales: Fixed Jaw Crushers in Action

1. Australian Mining Co. Enhances Iron Ore Output

At a major iron ore site in Western Australia, afixed jaw crusher model PE-400×600 processes over 350 tons of raw ore hourly. Its deep crushing chamber and high reduction ratio (4–6:1) ensure uniform particle sizes, critical for downstream smelting processes. The stationary jaw plates, made from manganese steel, withstand abrasive ore conditions, reducing replacement frequency by 40% compared to traditional designs.

2. Canadian Ore Processing Plant Adopts PEX Series

A Quebec-based facility uses thePEW-250×1200 fixed jaw crusher para aplastamiento secundario. With adjustable discharge settings (25–60 mm), it refines coarse iron ore into precise sizes for pelletizing. The electric drive system cuts energy consumption by 15%, aligning with the plant’s sustainability goals.

How Fixed Jaw Crushers Work for Iron Ore

Key Components and Crushing Mechanism

- Placa de mandíbula fija: The stationary component against which ore is compressed.

- Placa de mandíbula móvil: Driven by an eccentric shaft, it creates a reciprocating motion to crush material.

- Placa de palanca: Ensures safe overload protection and efficient power transmission.

The process begins with raw iron ore fed into the chamber. As the movable jaw exerts force, ore is crushed against the fixed plate until it reaches the desired size and exits through the discharge gap.

Advantages of Fixed Jaw Crushers in Ore Processing

- High Durability: Reinforced frames and wear-resistant plates (P.EJ., tungsten carbide or manganese steel) extend operational life in abrasive environments.

- Low Maintenance: Simple design reduces downtime. Routine checks on lubrication and fasteners ensure smooth operation.

- Eficiencia energética: Advanced motor designs and optimized crushing chambers lower power consumption per ton.

For installations in harsh climates, such as Scandinavian iron mines, these crushers are equipped with anti-freeze lubrication systems to maintain performance at sub-zero temperatures.

Maintenance and Installation Best Practices

Pre-Startup Checklist for Fixed Jaw Crushers

- Lubricación: Ensure toggle plates and bearings are adequately greased.

- Fastener Inspection: Tighten bolts to prevent vibration-induced loosening.

- Crushing Chamber Cleanliness: Remove debris to avoid blockages.

For detailed guidelines, refer to ourJaw Crusher Installation guide.

Energy-Saving Innovations in 2025 Modelos

Modernoenergy-saving jaw crushers integrate smart technologies:

- Unidades de frecuencia variable (VFDS): Adjust motor speed based on feed load, reducing idle power use by 20%.

- Composite Materials: Lightweight yet durable components lower energy demands without compromising strength.

Explorar nuestroTrituradores de la mandíbula que ahorran energía page for the latest advancements.

2025 Price Trends: Balancing Cost and Performance

A2025 Comparación de precios de Jaw Crusher reveals that mid-sized fixed jaw units (P.EJ., PE-600×900) range from 50,000 to 80,000, depending on automation features and material quality. High-capacity models like the PE-1200×1500 exceed $150,000 but offer 30% higher throughput for large-scale operations.

Crushers de la mandíbula fija remain a cornerstone of iron ore processing, combining reliability with cutting-edge efficiency. Whether optimizing an existing plant or designing a new facility, selecting the right crusher—and maintaining it properly—ensures long-term profitability. For tailored advice, consult our experts or visit ourRompe mandíbulas resource hub.