Correo electrónico: [email protected]

trituradora de yeso

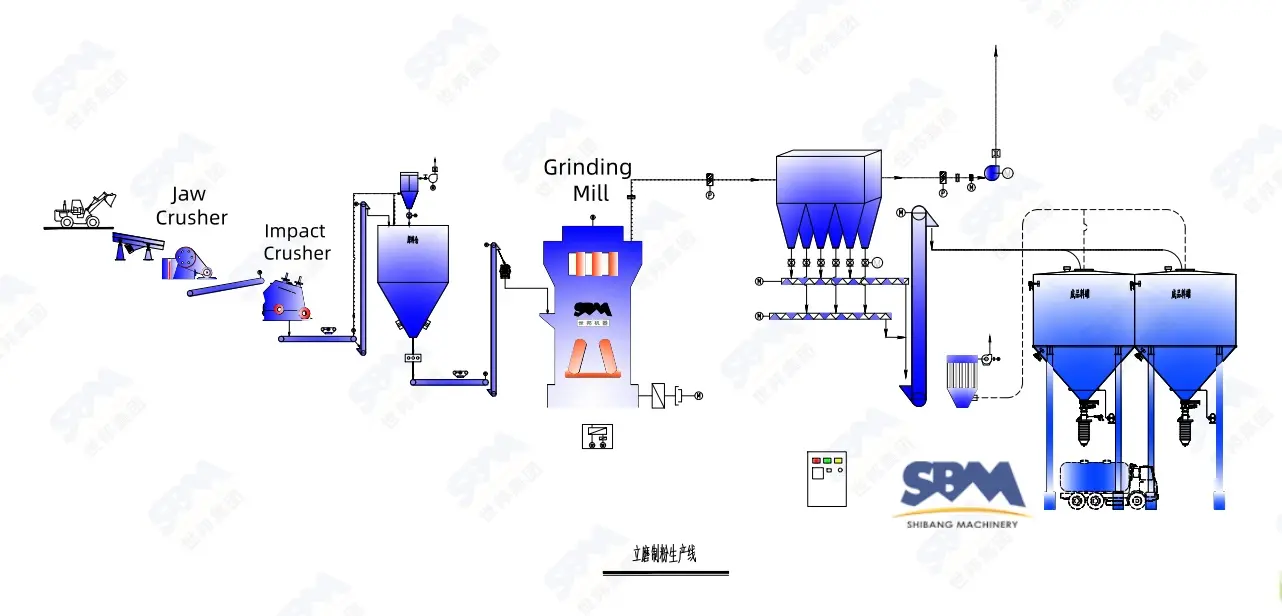

La trituradora de yeso SBM es un equipo clave para triturar grandes minerales de yeso. Los convierte en pequeños trozos de manera eficiente.. También proporcionamos trituradoras portátiles y móviles según los requisitos del cliente.. Las trituradoras de yeso son ideales para materiales de tamaño mediano y pequeño., como el clinker, arena, carbón, y otros minerales. Shanghai SBM ofrece varios tipos, incluyendo la mandíbula, cono, impacto, trituradora de yeso movil. Estas máquinas utilizan tecnología avanzada de trituración nacional e internacional.. además de trituradoras, Shanghai SBM también fabrica molinos de yeso y equipos auxiliares relacionados para el procesamiento de yeso..

Tipos y aplicaciones de trituradoras de yeso SBM

Una trituradora de yeso es una máquina diseñada para triturar grandes minerales de yeso en tamaños más pequeños.. Shanghai SBM es un importante fabricante y proveedor de trituradoras de yeso en China. Producimos trituradoras de mandíbulas primarias y secundarias., trituradora de impacto, trituradora hidraulica, y cuatro tipos de trituradora de cono para trituración de yeso. También se encuentran disponibles trituradoras portátiles y móviles para satisfacer las diversas necesidades de los clientes..

Las trituradoras de yeso SBM utilizan la última tecnología de trituración nacional y extranjera, como sistemas de impacto y martillo. Se utilizan principalmente para triturar yeso., materias primas de cemento, clinker de arena, mineral de hierro, carbón, y otros minerales. También funcionan bien en lugares de difícil acceso..

Shanghai SBM se centra en máquinas trituradoras de yeso y plantas trituradoras completas. Brindamos soluciones fijas y móviles., incluyendo la mandíbula, cono, y trituradora de impacto, junto con plantas de cribado móviles. Nuestra trituradora móvil es muy popular entre los clientes.. Si desea comprar una trituradora de yeso en India o Rusia, SBM es su mejor opción para un procesamiento eficiente de yeso.

Comparación de productos: trituradoras de yeso sbm

| Modelo | Tamaño máximo de alimentación (milímetro) | Capacidad (t/h) | Fuerza (kilovatios) | Tamaño de salida típico (milímetro) | Características clave |

|---|---|---|---|---|---|

| CI5X1110 | 500 | 110-260 | 160-200 | <40 | Alta eficiencia, ajuste hidráulico |

| CI5X1213 | 550 | 145-350 | 200-250 | <35 | Rotor robusto |

| CI5X1315 | 600 | 200-450 | 250-315 | <30 | Tecnología avanzada |

| CI5X2023 | 1300 | 1000-2100 | 1000-1260 | <20 | De servicio pesado, gran escala |

Todos los modelos son aptos para yeso y minerales similares., con funciones de ajuste rápido y soporte confiable para piezas de repuesto.

Visualización de su decisión sobre la trituradora de yeso

| Factor clave | Por que importa | Solución SBM |

|---|---|---|

| Eficiencia de trituración | Mayor producción, menor costo de energía | Rotores de alta resistencia, hidráulica inteligente |

| Capacidad de ajuste | diferentes materiales, necesidades de tamaño | Ajuste del espacio de descarga sin herramientas |

| Simplicidad de mantenimiento | Minimiza el tiempo de inactividad, larga vida útil del equipo | Piezas digitales, red mundial de apoyo |

| Disponibilidad de repuestos | Garantiza que la producción no se interrumpa | Repuestos localizados, envío rápido |

| Automatización | Reduce la mano de obra, mejora la seguridad & exactitud | Sistemas automatizados, monitoreo remoto |

Qué considerar al comprar una trituradora de yeso

Dureza y humedad del material

La dureza Mohs del yeso es baja., por lo que tanto la trituradora de impacto como la trituradora de mandíbulas son efectivas. Para material mojado o pegajoso, elija un diseño con fácil limpieza y amplia descarga.

Capacidad & Rendimiento

Calcule las toneladas por hora requeridas. (HTP). El sobredimensionamiento puede desperdiciar energía, pero el tamaño insuficiente conduce a una baja productividad. Modelos SBM de referencia para rangos de rendimiento flexibles aptos tanto para operaciones pequeñas como para tareas de alta capacidad.

Salida de tamaño de partículas

¿Cuál es su tamaño objetivo?? Para la producción de polvo fino, seleccione una trituradora con descarga regulable o una integrada con un molino.

Automatización y Mantenimiento

Los controles hidráulicos y el fácil acceso a las piezas de repuesto son importantes para reducir el tiempo de inactividad. La trituradora SBM está diseñada para cambios de piezas sin herramientas, ajustes rápidos, y acceso rápido a los suministros necesarios.

Confiabilidad y soporte

Considere proveedores que ofrezcan no solo equipos, pero soporte integral en el sitio, piezas de repuesto, capacitación, y servicio postventa. Reputación de marca, como el de SBM, añade confianza y garantiza la continuidad.

Hoja de referencia del comprador: Preguntas imprescindibles

- ¿Cuál es el tamaño máximo de mi yeso crudo??

- ¿Qué tamaño exacto y cantidad de producción necesita??

- ¿Necesita equipo móvil o fijo en su sitio??

- ¿Estás listo para la instalación y el mantenimiento diario??

- ¿Cómo accedo a piezas y soporte técnico rápido??

El uso de estas preguntas durante las cotizaciones y negociaciones puede mantener a los proveedores responsables y garantizarle el mejor trato..

Preguntas frecuentes (Preguntas frecuentes)

Absolutamente! Trituradora de impacto, como los hechos por SBM, También se puede utilizar para triturar materiales como piedra caliza., baritina, dolomita, y talco.

Para uso intensivo o múltiples turnos de trabajo, Los sistemas hidráulicos automáticos agilizan las tareas diarias., menores costos laborales, y mantener las máquinas funcionando por más tiempo.

SBM no sólo proporciona máquinas, pero también ofrece ayuda con la configuración del sitio., capacitación, suministro de piezas, y soporte local para garantizar un uso a largo plazo sin problemas y sin preocupaciones.

Siga la guía de la máquina para los tipos de aceite.. Generalmente, ISO 150 o se sugieren aceites hidráulicos específicos para las piezas de la trituradora para mantener la máquina funcionando sin problemas y durando más tiempo..

El sobrecalentamiento puede ocurrir debido a enfriadores de aceite bloqueados, problemas con el sistema de lubricación, o fallas mecánicas. Comprobación de la temperatura del aceite, presión, y la carga diaria de la trituradora ayuda a detener el sobrecalentamiento.

Las causas incluyen pernos flojos., acumulación de material en las piezas, contrapesos desgastados, o daño a la estructura. Los controles y el mantenimiento periódicos ayudan a solucionar este problema..

Preguntas frecuentes sobre la trituradora de yeso expandido

Las razones más comunes son revestimientos de manganeso desgastados o cambios repentinos en el tipo de material de alimentación., lo que puede causar bloqueos o un menor rendimiento de trituración..

El bloqueo suele deberse a que materiales no deseados, como metal o madera, que no se pueden triturar, entran en la trituradora.. Quitar estos materiales y mantener un flujo constante de lubricación ayuda a detener los bloqueos..

Comprobar periódicamente las piezas desgastadas, mantenimiento del sistema de lubricación, filtros de limpieza, y mantener un registro de mantenimiento son todos importantes para un rendimiento confiable.

Calibrar la configuración y las pantallas de la trituradora, monitorear la calidad de la producción diariamente, y ajuste los parámetros de alimentación y descarga según sea necesario para mantener un tamaño de salida uniforme.

Los operadores deben usar cascos, gafas de seguridad, protección para los oídos, y guantes. Seguir los procedimientos de bloqueo/etiquetado durante el mantenimiento garantiza la seguridad alrededor de las piezas móviles.

Para turnos de trabajo pesados o largos, La automatización reduce el trabajo., aumenta el tiempo de ejecución, y hace que el trabajo sea más seguro. Los controles hidráulicos y el monitoreo remoto son características automatizadas comunes en las trituradoras actuales..

Los operadores deben controlar el polvo., contaminación del aire, ruido, y residuos adecuadamente siguiendo las normas de calidad del aire y el agua para evitar multas y proteger las áreas cercanas.

Tengo más preguntas? Estamos aquí para ayudar!

Si tienes alguna inquietud específica, consultas técnicas, o necesita asesoramiento sobre cómo elegir la trituradora de yeso adecuada para su operación, no dudes en comunicarte. Nuestro equipo de expertos está listo para brindar soporte personalizado y responder cualquier pregunta que pueda tener..