پست الکترونیک: [email protected]

چه اندازه سنگ خرد شده برای دال بتونی حداکثر استحکام را فراهم می کند?

چه اندازه سنگ خرد شده برای دال بتنی حداکثر قدرت را ارائه می دهد? مناسب ترین اندازه سنگ خرد شده برای صفحات بتونی مانند Driveways, پاسیوس, طبقه, و غیره. است. است 19 میلی متر (3/4 اینچ). این به این دلیل است که این اندازه سنگ خرد شده بهترین تعادل را بین استحکام سازه و کارایی ایجاد می کند. سنگدانه های ریزتر (به عنوان مثال. 10 میلی متر/3/8 اینچ) افزایش چگالی اما کاهش نفوذپذیری. سنگدانه های درشت تر (به عنوان مثال. 40 میلی متر/1.5 اینچ) نفوذپذیری را افزایش می دهد اما بر روی سطح تأثیر می گذارد.

چرا اندازه سنگ خرد شده برای صفحات بتنی مهم است؟?

اندازه سنگ خرد شده می تواند به طور مستقیم بر ظرفیت باربری تأثیر بگذارد, مقاومت در برابر ترک, و طول عمر دال بتنی. برای دال های بتنی که بارهای سنگین را تحمل می کنند, مانند راهروها یا کف های صنعتی, مخلوط کردن 3/4-سنگ خرد شده اینچ با اندازه های کوچکتر می تواند تراکم را تا 15% در مقایسه با یک سنگ خرد شده تک اندازه.

بهینه سازی عملکرد بتن: اندازه ها و کاربردهای سنگ خرد شده

انتخاب اندازه سنگ خرد شده مناسب از فرورفتن دال و پوسته شدن سطح جلوگیری می کند. اگر می خواهید در مورد اندازه های سنگ خرد شده بیشتر بدانید, شما می توانید بررسی کنید نمودار اندازه سنگ خرد شده. در اینجا نحوه هماهنگی اندازه ها با برنامه ها آمده است:

- 3/8-اینچ (10میلی متر): ایده آل برای اسلب های تزئینی نازک (<4 اینچ ضخامت). پوشش های صاف را ارائه می دهد اما زهکشی را محدود می کند.

- 3/4-اینچ (19میلی متر): انتخاب جهانی برای دال هایی با ضخامت 4 تا 6 اینچ (پاسیوس, پیاده رو). قدرت و کارایی را متعادل می کند.

- 1.5-اینچ (40میلی متر): در پی های عمیق یا جاده ها استفاده می شود. بیش از حد درشت برای اکثر دال ها - باعث ناهمواری سطح می شود.

جدول: اندازه های سنگ خرد شده برای کاربردهای بتن

| اندازه سنگ | ضخامت دال | بهترین برای | سختی تراکم |

|---|---|---|---|

| 3/8-اینچ (10میلی متر) | <4 اینچ | بتن تزئینی | کم |

| 3/4-اینچ (19میلی متر) | 4-6 اینچ | پاسیوس, مسیرهای رانندگی, طبقه | معتاد |

| 1.5-اینچ (40میلی متر) | >6 اینچ | جاده ها, پایگاه های صنعتی | عالی |

چرا سنگ 3/4 اینچی بر ساخت دال غالب است؟?

تمام شد 70% استفاده از اسلب مسکونی و تجاری 3/4-سنگ خرد شده اینچ2. لبه های زاویه ای آن پیوندهای اصطکاکی ایجاد می کنند که در برابر جابجایی مقاومت می کنند, در حالی که اندازه آن به خمیر سیمان اجازه می دهد تا ذرات را به طور کامل بپوشاند. پروژه هایی که از این اندازه استفاده می کنند نشان می دهد 20% مقاومت فشاری بالاتر نسبت به آنهایی که سنگهای بزرگتر دارند.

از معدن تا اسلب: سفر سنگ 3/4 اینچی

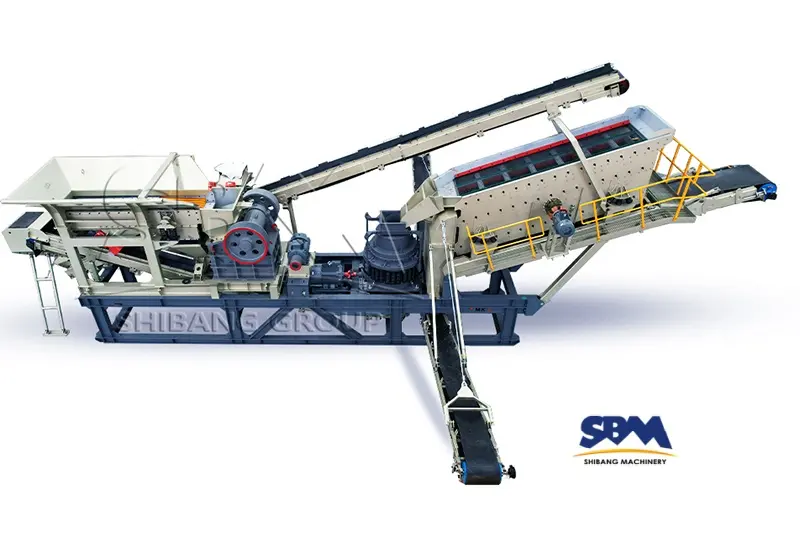

- خرد کردن: سنگ شکن های فکی سنگ های انفجاری را به قطعات 6 تا 8 اینچی بشکنید.

- خرد کردن ثانویه: سنگ شکن های مخروطی تکه ها را به 1-3 اینچ کاهش می دهند.

- غربالگری سوم: صفحه نمایش های لرزان ذرات 3/4 اینچی را از هم جدا می کنند, با مواد بیش از اندازه در چرخش مجدد.

کارخانه های مدرن مانند سنگ شکن های متحرک SBM این مراحل را ادغام می کنند, تولید 200 تا 500 تن در ساعت سنگ کاملاً درجه بندی شده.

فراتر از اندازه: 4 عوامل حیاتی هنگام استفاده از سنگ خرد شده در اسلب

- آن را بشویید! گرد و غبار یا ذرات پوشش خاک رس چسبندگی خمیر را کاهش می دهد. سنگ را با <1% محتوای سیلت.

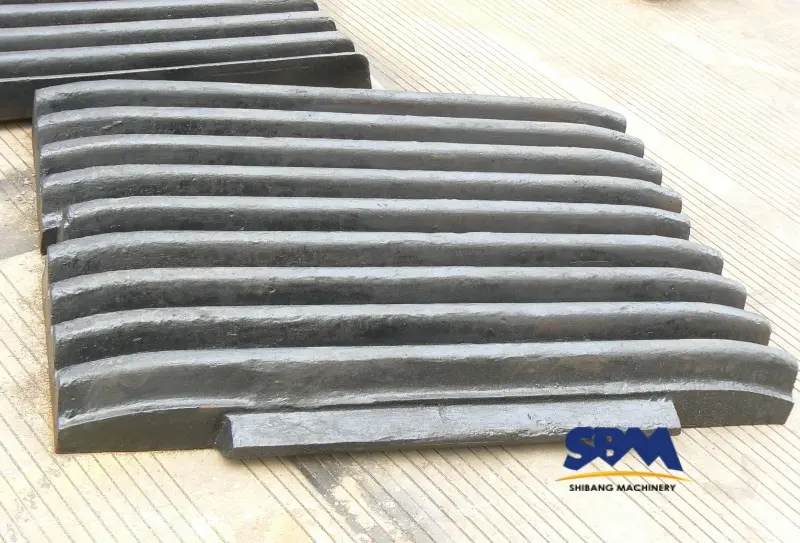

- Angularity > Smoothness: لبه های دندانه دار (از گرانیت / سنگ آهک) در هم قفل شدن بهتر از شن گرد است.

- ضخامت لایه: برای اسلب, پایه سنگ فشرده را محدود کنید 6 اینچ. لایه های ضخیم تر باعث ته نشین شدن می شوند.

- کنترل رطوبت: سنگ قبل از ریختن باید مرطوب باشد - سنگ خشک استخوان آب را از مخلوط میدزدد, تضعیف هیدراتاسیون.

مطابقت سنگ شکن با اندازه سنگ: راهنمای تجهیزات شما

- سنگ شکن فک: قلوه سنگ های اولیه 6 تا 8 اینچی ایجاد کنید. برای خرد کردن اولیه با حجم زیاد استفاده کنید.

- سنگ شکن مخروط: کاهش دقت به 3/4 اینچ. ایده آل برای سنگ های با سختی بالا مانند بازالت.

- سنگ شکن ضربه: سنگ های کوچکتر تولید کنید (3/8-اینچ) با اشکال مکعبی برای پرداخت صاف.

جدول: انتخاب سنگ شکن بر اساس اندازه خروجی و کاربرد

| نوع سنگ شکن | محدوده اندازه خروجی | بهترین انواع سنگ | ظرفیت تولید |

|---|---|---|---|

| سنگ شکن فکی | 4-8 اینچ | سنگ گرانیت, بازالت | 100800 تن در ساعت |

| سنگ شکن مخروطی | 3/8-3 اینچ | سنگ آهک, کوارتزیت | 50-500 تن در ساعت |

| سنگ شکن ضربه ای | 3/8-1 اینچ | سنگ نرم تر, بازیافت | 30-300 تن در ساعت |

خرد کردن سنگ خود را: 5 مزایای بی نظیر

- کاهش هزینه: خرد کردن در محل هزینه های حمل و نقل را تا 40٪ کاهش می دهد - بدون واسطه.

- درجه بندی های متناسب: اندازه های دقیق را با هم ترکیب کنید (به عنوان مثال،, 3/4-اینچ با پرکننده 3/8 اینچی مخلوط شده است) برای تراکم بهینه دال.

- بازیافت زباله: خرد کردن بقایای بتن به سنگدانه های جدید سازگار با محیط زیست و سازگار با ASTM.

- کنترل سازگاری: تنظیمات سنگ شکن را روزانه برای حفظ یکنواختی اندازه تنظیم کنید (± 3 میلی متر).

- مدیریت گرد و غبار: سنگ شکن های مدرن مانند SBM شامل سیستم های اسپری هستند, کاهش گرد و غبار سیلیس توسط 90%.

سنگ خرد شده در مقابل. شن: مسابقه بتن

- سنگ خرد شده (3/4-اینچ): سطوح زاویه دار باعث تقویت پیوند مکانیکی می شوند. اسلب ها نشان می دهد 30% استحکام خمشی بالاتر نسبت به بتن شنی.

- شن: لبه های گرد تقاضای آب را کاهش می دهد (برای کارایی خوب است) اما مقاومت در برابر ترک را کاهش می دهد. رزرو برای دال های غیر سازه ای.

در جایی که پیمانکاران سنگهای خرد شده را جایگزین سنگریزههای رودخانهای میکردند، در طی یک سال، دالها را بهطور مستقیم از کار میاندازند., ترک های تار عنکبوت در سراسر سطح. در مورد سنگدانه های زاویه دار برای بتن باربر سازش نکنید.

انتخاب سنگ شکن شما: 3 ملاحظات ساخت یا شکستن

- نیازهای توان عملیاتی: برای اسلب زیر 1,000 فوت مربع, ترکیبات فک/مخروط موبایل (مانند سری K SBM) دسته 150 تن در ساعت.

- سختی سنگ: تقاضای گرانیت/بازالت سنگ شکن های مخروطی; سنگ آهک نرم تر با سنگ شکن ضربه ای کار می کند.

- انعطاف پذیری اندازه: به دنبال تنظیم هیدرولیک باشید - خروجی را از 3/4 اینچ به 3/8 اینچ در چند دقیقه تغییر دهید.

تسلط بر اندازه سنگ خرد شده دال های بتنی را از کافی به استثنایی تبدیل می کند. با قفل کردن سنگ 3/4 اینچی در مشخصات خود, دقیقاً کنترل درجه بندی, و استفاده از سنگ شکن های مدرن, شما اسلب هایی خواهید ساخت که چندین دهه استفاده را تحمل می کنند. هر کارخانه سنگ شکنی که من حسابرسی کردهام و غربالگری چند مرحلهای را اتخاذ کردهاند، شاهد کاهش چشمگیر در تماسهای دالها بودهاند - اثبات این که هوش اندازه کارآمد است..

دفتر مرکزی

واتساپ:+8615225176731

پست الکترونیک: [email protected]

نشانی: خیر. 1688, جاده شرقی گائوک, ناحیه جدید پودونگ, شانگهای, چین.

سایت اینترنتی: https://www.mill-sbm.com/