پست الکترونیک: [email protected]

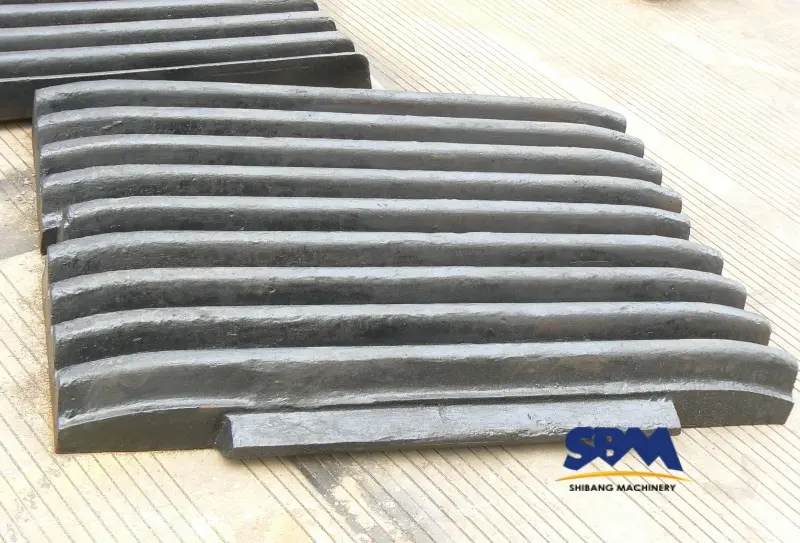

راهنمای گام به گام برای جایگزینی آستر خرد کننده فک: 8 مراحل کلیدی

درست تعویض آستر شکن فک راندمان تولید را افزایش می دهد 40% و زندگی مؤلفه را توسط 2-3 سال. این راهنمای جامع جزئیات تکنیک های حرفه ای مورد استفاده درعملیات معدن کوچک و بزرگ, پوشش پروتکل های ایمنی, ابزار ابزار, و روشهای هم ترازی دقیق. فرآیند 8 فاز ما را دنبال کنید تا به حداقل رساندن خرابی در زیر 4 ساعت در هر تعویض.

آماده سازی قبل از راه اندازی

1. روش قفل ایمنی

- منبع تغذیه را قطع کنید و قفل مکانیکی را درگیر کنید

- فشار هیدرولیکی را آزاد کنید (> 5 دقیقه زمان خونریزی)

- محافظت از پاییز را برای دسترسی به گودال شستشو نصب کنید

2. ابزار & فهرست مواد

| ابزار | مشخصات |

|---|---|

| جک هیدرولیک | 50-ظرفیت تن |

| آچار گشتاور | 300-800 دامنه n · m |

| گیره بلند کردن | SWL 2000 کیلوگرم |

فرآیند تعویض آستر

3. آسترهای فرسوده را بردارید

- پیچ های گوه را در الگوی مورب شل کنید (30% کاهش گشتاور)

- استفاده کردنابزارهای حذف آستر برای شکستن پیوند خوردگی

- ابتدا گوه های فوقانی را استخراج کنید, سپس صفحات جانبی

4. تمیز & سطح نصب را بازرسی کنید

- زباله ها را با اسکنه پنوماتیک بردارید

- با استفاده از نفوذ رنگ ، ترک ها را بررسی کنید

- صافی را تأیید کنید (تحمل 0.5 میلی متر در متر)

5. آسترهای جدید را نصب کنید

| جزء | مشخصات گشتاور | ترتیب |

|---|---|---|

| فک ثابت | 650 n · m | محور |

| فک متحرک | 720 n · m | الگوی متقاطع |

6. تأیید صحت

برای اطمینان از ابزارهای تراز لیزر استفاده کنید:

- موازی سازی 0.2 میلی متر در متر

- Runout عمودی 0.3 میلی متر

- مناسبهندسه محفظه خرد

مراحل پس از نصب

7. فرآیند دویدن

- شروع کردن 50% نرخ خوراک برای 2 ساعت

- لرزش (< 4.5 میلی متر در ثانیه RMS)

- پس شدن 8 ساعت کار

8. مستندات & تجزیه

- شماره سریال های خطی را ضبط کنید

- الگوی سایش اولیه را اندازه گیری کنید

- بروزرسانیبرنامه نگهداری پیش بینی کننده

اشتباهات رایج & راه حل

| خطا | نتیجه | پیشگیری |

|---|---|---|

| گشتاور نادرست | حرکت | از آچار کالیبره شده استفاده کنید |

| تراز از دست رفته | سایش زودرس | تأیید لیزر |

بهبود بهره وری معدن

یک عمل سنگ آهک باعث کاهش زمان تعویض بوش از 6.5 به 3.8 ساعت:

- اجرای روند 8 مرحله ای ما

- با استفاده از پروفایل های بهینه سازی شده

- خدمه تمرینی در مورد سینماتیک سنگ شکن

ابزارهای اساسی برای جایگزینی کارآمد

- کنترل کننده آستر با آسانسور خلاء

- دوربین حرارتی مادون قرمز (دمای تحمل را بررسی کنید)

- سنج ضخامت دیجیتال (اندازه گیری)

دقت باعث صرفه جویی در هزینه ها می شود

تعویض آستر شکن فک نیاز به درک مشخصات گشتاور دارد, تحمل تراز, و روشهای مناسب اجرا. از این رو, با ادغام این راهنما با برنامه نگهداری پیشگیرانه ومستند سازی تجهیزات, عملیات به طور معمول به دست می آیند 18-24 چرخه های ماهواره ماه حتی در شرایط ساینده.

دفتر مرکزی

واتساپ:+8615225176731

پست الکترونیک: [email protected]

نشانی: خیر. 1688, جاده شرقی گائوک, ناحیه جدید پودونگ, شانگهای, چین.

سایت اینترنتی: https://www.mill-sbm.com/