پست الکترونیک: [email protected]

راهنمای انتخاب صفحه فک: عملکرد را برای عملیات خرد کردن خود بهینه کنید

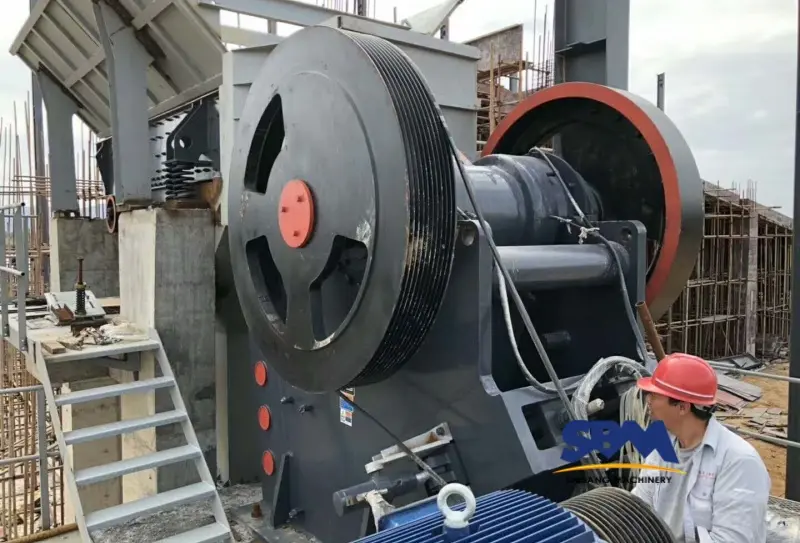

Choosing the right jaw plates can increase yourراندمان خرد کننده از طرف 25-40% در حالی که هزینه های تعویض را کاهش می دهد. This comprehensivejaw plate selection guide explains how material composition, طراحی پروفیل دندان, و شرایط عملیاتی طول عمر صفحه را تعیین می کند. چه از یک سنگ شکن فکی C6X یا مدل های قدیمی تر استفاده کنید, these insights will help you make informed decisions.

Key Factors in Jaw Plate Selection

Material Composition Choices

Modern jaw plates use three primary materials:

- فولاد منگنز (14-18%): Ideal for general-purposequarry applications, withstands 50-70k tons before replacement

- Chrome Iron Alloy: 30% longer lifespan in abrasive materials like granite

- Ceramic-Enhanced: Reduces wear by 45% in high-silica content operations

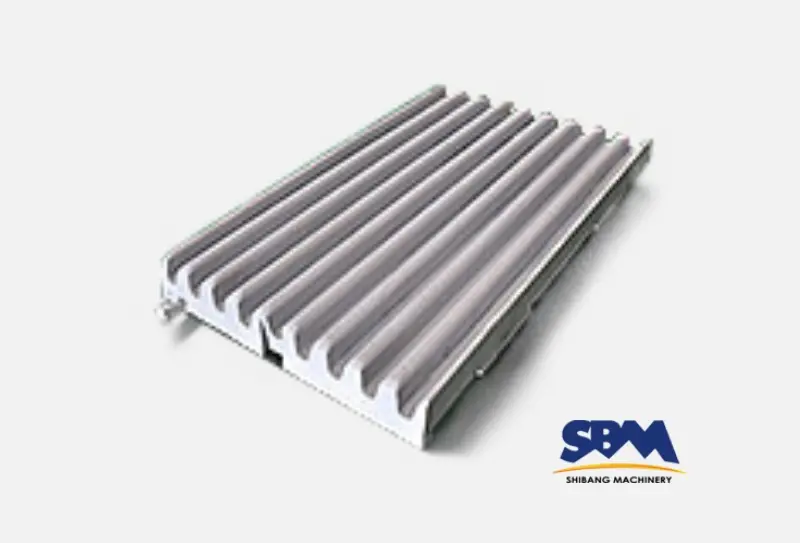

Tooth Profile Design Considerations

The plate’s tooth configuration directly impacts yourcrusher’s working mechanism:

| Profile Type | بهترین برای | محدوده اندازه خروجی |

|---|---|---|

| Straight | خرد کردن | 150-300 میلی متر |

| Waved | Secondary reduction | 50-120 میلی متر |

| هیبرید | Mixed material feeds | 30-150 میلی متر |

4-Step Selection Process

- Analyze Feed Material: Test hardness (مقیاس موهس) and abrasiveness

- Determine Crusher Type: سنگ شکن فکی سری C6X requires specific plate locking systems

- Calculate Economic Lifespan: Balance initial cost vs tons crushed/$

- Verify Compatibility: Check mounting system dimensions (±2mm tolerance)

Maintenance Synergy: Plates and Crusher Health

مناسبjaw crusher maintenance extends plate lifespan by 60%:

- Rotate plates every 200-300 ساعات کار

- Maintain correct CSS settings (affects wear patterns)

- Use laser alignment tools for precise installation

مطالعه موردی: بهینه سازی معدن گرانیت

A Brazilian operation achieved 32% cost reduction by:

- Switching from standard Mn14 to Mn18Cr2 plates

- Implementing bi-weekly wear measurements

- Syncing replacements with scheduled maintenance downtime

تکنیک های نظارت پیشرفته

- 3D wear scanning for precise remaining thickness analysis

- AI-powered wear rate prediction models

- Ultrasonic hardness testing for material verification

Common Selection Mistakes

- Choosing cheap plates needing 3x more frequent replacement

- Ignoring material compatibility (به عنوان مثال،, zinc contamination)

- Overlooking plate weight impacts on crusher kinematics

Strategic Selection Pays Dividends

تسلطانتخاب صفحه فک requires understanding your material, نوع ماشین (like C6X models), and operational goals. Pair this guide with regular preventive maintenance to achieve 18-24 month plate lifespans even in demanding conditions. یادآوری کردن: The optimal plate today may differ tomorrow – re-evaluate selections with major material changes.