E-mail: [email protected]

Gabbro écrasé

Maison » Pierre écrasée » Gabbro écrasé

Contenu principal

Let’s be honest, in our world, not all rock is created equal. We see a hundred different deposits, but when you find a solid gabbro formation, you know you’ve hit paydirt. Ce crushed gabbro is the workhorse of the aggregate world—dense, difficile, and in high demand for serious projects. But here’s the catch: you can’t just throw any old equipment at it and hope for the best. Processing gabbro efficiently is what separates a profitable operation from a money pit. I’ve been designing plants for this very purpose for decades, and I’m here to walk you through exactly how to turn that tough gabbro rock into a premium product your customers will fight over.

What Exactly Is Gabbro?

Before we talk about crushing it, let’s understand what we’re dealing with. Gabbro is the deep-down, slow-cooling cousin of basalt. It’s a coarse-grained, intrusive igneous rock, which is a fancy way of saying it formed from magma that got trapped underground and took its sweet time cooling off. This slow dance is what gives it its magic: a fantastic interlocking crystal structure. In practical terms? That means unbelievable compressive strength, killer abrasion resistance, and a density that makes it feel heavy in your hand. This isn’t your average limestone. This is the rock you specify for jobs that absolutely cannot fail.

Why Gabbro? The Business Case for a Premium Aggregate

“Why should I go through the hassle?” I get it. Calcaire is easier on the crushers. But with easier processing comes a cheaper product. Gabbro is your ticket to the premium market. Its physical properties are simply unmatched for heavy-duty applications. That high density makes it perfect for weight-bearing projects and even radiation shielding. Its resistance to wear and weathering means it outlasts everything else in asphalt and concrete. You’re not just selling crushed rock; you’re selling longevity and performance. And that means better margins and a reputation for quality that brings customers back.

Size of Crushed Gabbro: Your Product Lineup

The end-game is all about size of crushed gabbro. Your entire plant design revolves around hitting these specific specs to meet market demand. Faire les choses, and you’ve got a product for every buyer. Get it wrong, and you’re left with a pile of out-of-spec rock. Here’s the cheat sheet every plant manager needs on their wall.

| Target Size (millimètre) | What We Call It | Where It Ends Up |

|---|---|---|

| 50 – 100 | Coarse Aggregate | Ballast ferroviaire, Riprap, Contrôle de l'érosion |

| 20 – 50 | Medium Aggregate | Base de route, Sub-base, Concrete Aggregate |

| 5 – 20 | Agrégat fin | Asphalt Mix, Pre-cast Concrete, Drainage |

| 0 – 5 | Crusher Dust / Fines | Pipe Bedding, Aménagement paysager, Mill Feed |

| < 0.063 | Fine Powder | Soil Amendment, Industrial Fillers |

This table is your business plan. Your crushers and screens are there to sort this stuff as efficiently as possible. Every fraction is a different revenue stream. The goal is to minimize waste and maximize yield on the high-value sizes.

Who’s Buying This Stuff? The Applications of Crushed Gabbro

You’re not just making little rocks out of big rocks. You’re engineering a product for a specific job. Knowing where your gabbro ends up tells you exactly what your customers need.

1. Ballast ferroviaire: Holding the Line

This is one of the most punishing jobs for any aggregate. Ballast has to bear the immense load of a train, drain water instantly, and resist movement. The sharp, angular edges of your crushed gabbro are perfect for this. They interlock like a 3D puzzle, creating a stable bed that won’t shift. The size is critical here—typically a tight 40mm to 60mm spec. If you can consistently hit this, you’ve got a steady market.

2. High-Performance Asphalt Aggregate

For high-traffic roads, motorways, and airport runways, they need the good stuff. The angular shape of gabbro aggregate provides incredible shear resistance and binds tenaciously with the bitumen. This reduces rutting and deformation under those massive loads. It’s a premium choice for the surface course where failure is not an option.

3. High-Strength Concrete Aggregate

In concrete, it’s all about the bond. The rough, crystalline texture of crushed gabbro creates a superior mechanical bond with the cement paste. Le résultat? Concrete with higher compressive and flexural strength. Ready-mix and pre-cast producers looking for a superior mix will seek this out.

4. Construction Road Base and Sub-base

Before the pretty stuff goes down, you need a foundation that won’t quit. Compacted gabbro aggregate forms a robust, unyielding base layer that distributes loads and prevents settlement. It’s the unsung hero that ensures the pavement above it lasts for decades.

5. Riprap and Armor Stone: Fighting Erosion

Along shorelines and riverbanks, you need big, lourd, durable stones to armor against erosion. The high density and interlocking nature of large crushed gabbro rock make it ideal for this. It’s literally about holding the line against nature’s force.

The Gear: Choosing Crushers That Can Take a Beating

Bien, let’s talk hardware. This is where the rubber meets the road. Gabbro is abrasive. It’s tough. It will eat poorly made crushers for breakfast. You need robust, purpose-built machines. Here’s my take on the lineup you need.

Écrasement primaire: The Jaw Crusher – Your First Line of Defense

Everything starts here. Your primary crusher has to take the quarry’s biggest, meanest blocks (think over a meter across) and make them manageable. For that, nothing beats a good Concasseur à mâchoires. It’s all about brute force: a swinging jaw smashing against a fixed jaw in a cyclic compression that’s perfect for breaking gabbro’s spirit. Don’t cheap out here. You need a crusher with a massive, rigid frame and high-quality manganese steel jaws that can handle the abuse. A large feed opening is non-negotiable.

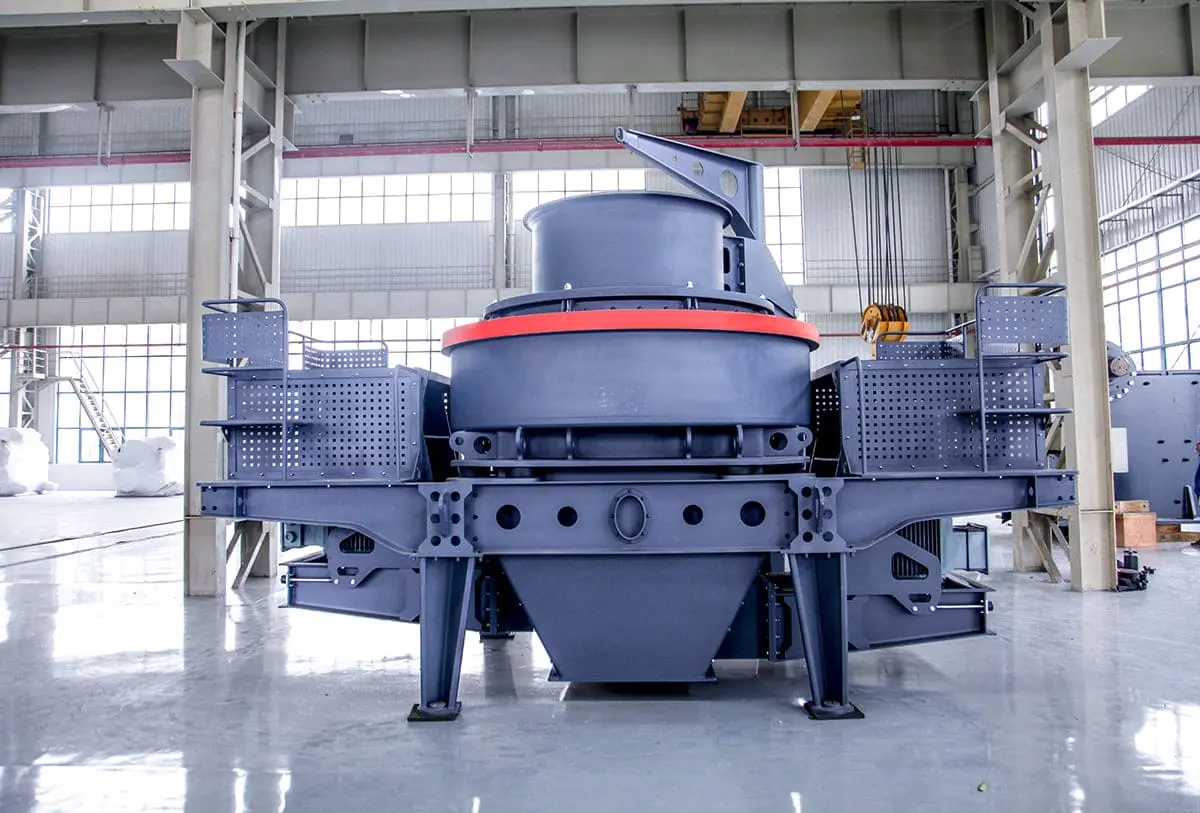

Écrasement secondaire: The Cone Crusher – The Heart of the Operation

After the jaw, the material is still way too coarse. This is where the real finesse begins with a Concasseur à cône. This is the workhorse. It reduces size by compressing rock between a gyrating spindle and a concave liner. For gabbro, you want a modern hydraulic cone crusher. Pourquoi? Because you need to adjust the closed-side setting (CSS) on the fly to dial in your product size perfectly. This precise control is what lets you hit those tight gradation specs for asphalt and concrete. It’s the difference between a sale and a pile of useless rock.

Tertiary/Fine Crushing: Squeezing Out Value

To get those smaller, more cubical aggregates (the 5-20mm range everyone wants), you often need a tertiary stage. My go-to is another, smaller cone crusher set for a fine crush. Some folks ask about impact crushers for the shape. And yeah, they can produce a nice cube. But let me tell you, for highly abrasive gabbro rock, the wear costs on concasseur à percussion parts will sink you. The maintenance downtime alone isn’t worth it. Rupture de cône, with their rock-on-rock crushing action, are far more economical in the long run. Trust me on this.

When Rocks Become Powder: The Grinding Game

Sometimes the market wants powder. Bien gabbro powder is used in agriculture or as a filler. This is a different ball game altogether, moving from crushing to grinding.

The Ball Mill: The Old Reliable

For getting down to 100 mesh or finer, un Broyeur à billes is a proven technology. It’s a rotating drum with steel balls inside that cascade and crush the feed through impact and attrition. It works, and it’s reliable, but let’s be frank—it’s an energy hog. The power bill on one of these can be staggering.

The Vertical Roller Mill (VRM): The Modern Workhorse

If you’re serious about powder and serious about your bottom line, you look at a Broyeur à rouleaux vertical. This is the tech that changed the game. It uses rollers to press and shear the rock against a spinning table. It’s way more energy-efficient than a ball mill, has a smaller footprint, and gives you excellent control over your product. For a new installation, this is the only logical choice for high-volume production.

Building the Flow: Designing Your Crush Gabbro Plant

Putting this all together is the fun part. A well-designed flow sheet is a beautiful thing. It’s like a symphony where every machine plays its part. Here’s a classic, reliable three-stage setup that I’ve seen work time and again.

Scène 1: Écrasement primaire & Dépistage

ROM gabbro gets fed to a vibrating grizzly feeder to scalp off the fines. The big stuff goes straight to the jaw crusher. The output from the jaw is then conveyed to a primary screen.

Scène 2: Écrasement secondaire & Classification (Closed Circuit)

The primary screen sorts the material. The oversize gets sent to our workhorse, the cone crusher. The discharge from that cone crusher is fed right back to the same screen. Ce “closed circuit” loop is crucial. It ensures that nothing moves forward until it’s small enough. This is how you control your size.

Scène 3: Écrasement tertiaire & Final Screening (Another Closed Circuit)

The on-spec material from the secondary circuit goes to a multi-deck screen. This is where the magic happens—it precisely splits the stream into your final products: ballast, base course, asphalt chips. Any oversize from this screen gets sent to a tertiary cone crusher for a final kiss, and its output is also fed back to the screen. Another closed circuit. This setup gives you incredible flexibility and lets you maximize production of whatever size is in highest demand.

Final Thought: It’s About Partnership

Choosing equipment for a gabbro operation isn’t a catalog order. It’s a strategic decision. The right partner doesn’t just sell you a machine; they help you design a system that maximizes your yield and minimizes your cost per ton for the life of the quarry. It’s about having someone who understands wear parts, maintenance cycles, and how to tweak a setting to get that perfect product. That’s the kind of partnership that makes a tough rock like gabbro your most profitable asset. Maintenant, let’s go crush it.