E-mail: [email protected]

Quais materiais são adequados para trituradores de impacto?

For anyone in the mining, pedreira, or recycling industries, picking the right crusher can make or break the entire operation. Not every material responds the same way to crushing, e trituradores de impacto have distinct strengths when dealing with specific types of rocks and waste. Vamos explorar which materials are suitable for impact crushers to help industry professionals make optimal decisions and drive plant profitability.

Which Materials Are Most Suitable for Impact Crushers?

1. Soft to Medium-Hard Natural Stones

- Calcário: Calcário is widely used for making cement, construindo estradas, and as gravel. It’s easy for impact crushers to handle because it’s not very hard, and the crushed pieces work well in concrete.

- Dolomite: Like limestone, dolomite breaks apart easily and makes nicely shaped stones for building.

- Gesso: Gypsum is used for making wallboard and plaster, and impact crushers quickly turn it into small pieces.

- Arenito: Sandstone breaks up well in impact crushers and creates strong, even gravel for making asphalt and concrete.

2. Resíduos de Construção e Demolição

Impact crushers shine in recycling applications. Materials include:

- Concreto: Concrete debris is easy to crush and turns into steady gravel that can be used to make new concrete.

- Asfalto: Old pavement—impact crushers turn it into ready-to-use material, making new roads more cost-effective and eco-friendly.

3. Industrial and Demolition Byproducts

- Vidro: Impact crushers quickly reduce glass to specific sizes for recycling.

- Scrap Metal: Lighter scrap metals can be broken down efficiently, aiding further processing and recycling stages.

4. Organic and Certain Sticky Materials

Mesa: Material Suitability for Impact Crushers

Not Recommended: Highly Abrasive and Very Hard Material

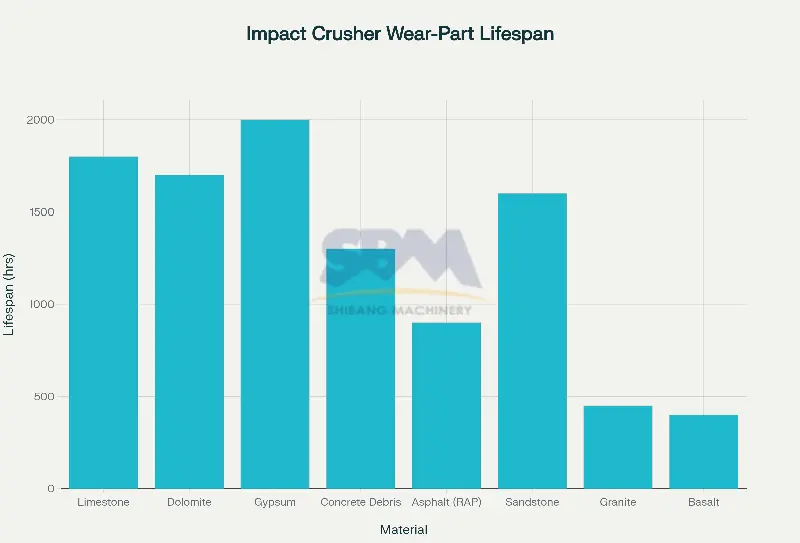

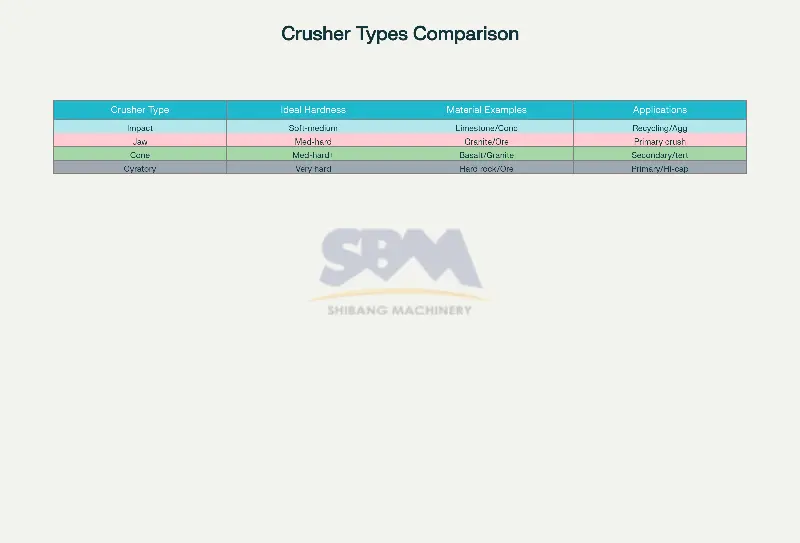

Materials like granito, basalto, quartzito, and ores that are harder than 6 on the Mohs scale aren’t a good match for impact crushers and usually need jaw or cone crushers instead. If you use trituradores de impacto for these materials, the parts can wear out quickly, causing more repairs and less working time.

Why Are These Materials a Great Fit?

Impact crushers use strong hits instead of squeezing pressure. This quickly breaks apart soft to medium-hard materials while keeping the stone’s shape. That’s why they’re hard to replace for making gravel and handling recycled materials.

Key Impact Crusher Parameters

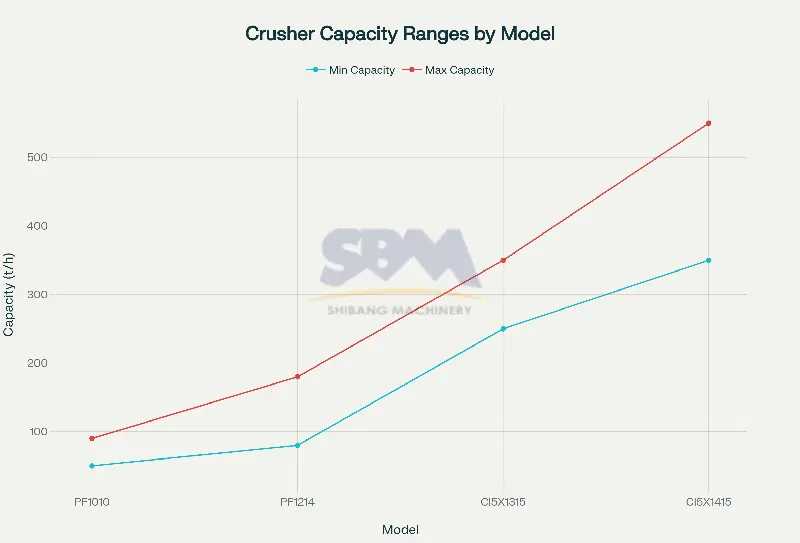

For professionals comparing different makes and models, here’s a glimpse of typical product parameters (drawn from SBM):

| Modelo | Especificações do rotor (milímetros) | Tamanho de entrada (milímetros) | Tamanho de entrada (milímetros) | Capacidade (º) | Poder (kw) |

|---|---|---|---|---|---|

| CI5X1315 | 1300×1500 | 1540×930 | 600 (≤300) | 250-350 | 250-315 |

| CI5X1415 | 1400×1500 | 1540×1320 | 900 (≤600) | 350-550 | 250-315 |

| PF series | — | Até 1300 | Até 600 | 50-2000 | — |

A larger rotor and feed opening accommodate bigger raw materials, which end up as highly uniform end products—crucial for quality-driven projects.

Practical Applications for Impact Crushers

Produção Agregada

In mining and quarrying, impact crushers can produce good quality, well-shaped gravel that supports making concrete, road bases, and construction fill.

Reciclagem (C&D, Vidro, Asfalto)

Impact crushers are great at changing waste into reusable materials, helping both the environment and cost savings in building and infrastructure.

Cement & Building Materials

The cement industry relies on impact crusher for their excellent ability to crush limestone and similar rocks, providing a uniform mix needed for the kiln.

Choosing the Right Impact Crusher: Erros comuns para evitar

- Wrong Material Pairing: Feeding highly abrasive rocks can burn out crusher parts and rack up repair bills.

- Overlooking Feed Size: Going beyond the recommended maximum size leads to blockages and downtime.

- Ignoring Wear Parts Quality: Not all blow bars and hammers are equal—ensure the correct metallurgy for specific material types.

Best Practices: Maximizing Impact Crusher Performance

- Pre-Screening: Remove oversize or tramp iron before crushing to lengthen wear part life and improve efficiency.

- Manutenção de rotina: Regularly inspect blow bars and hammers for wear, swapping them out before performance drops.

- Adjusting Settings: Tweak rotor speed and gap for specific material properties—this fine-tuning can have a huge impact on final output.

- Using the Right Parts: Choose manganese steel for tough jobs, chrome ferro for abrasion resistance, or advanced martensitic ceramics for maximum wear life.

Chart: Impact Crusher Material Compatibility and Wear Rates

Perguntas frequentes (Perguntas frequentes)

What’s the advantage of impact crushers in recycling?

Impact crushers excel at producing cubical, high-quality recycled aggregates from C&D waste, vidro, e asfalto, making the materials suitable for reuse in new construction or paving.

Can impact crushers handle granite or basalt?

Not recommended—these hard, highly abrasive rocks can wear down impact crusher parts rapidly. Use mandíbula ou britador de cone for such tasks.

What’s the typical feed size for an impact crusher?

Depending on the model, input sizes can range from a few centimeters to up to 600–900 mm.

Making an Informed Decision

Choosing the best materials for impact crushers helps your business run smoothly, lets your machines last longer, and gives you better products. If you work with softer or medium-hard rocks, recycled gravel, or some industrial leftovers, impact crushers are still one of the best options—they’re flexible, acessível, and can help protect the environment in mining and recycling.

Suggested Additional Tables & Charts

- Wear Rates by Material Type: Shows how long different rocks will let crusher parts last.

- Impact Crusher vs. Outros tipos de britadores: Easy comparison to show what materials each crusher is best for.

- Capacity Ranges by Model: Compares how much different crushers can handle.

If you need more technical info or want to see special impact crusher models or spare parts, ask a trusted supplier. Always make sure you use a crusher that matches your site’s materials for the best results.

Sede Escritório

Whatsapp:+8615225176731

E-mail: [email protected]

Endereço: Não. 1688, Gaoke East Road, Novo distrito de Pudong, Xangai, China.

Local na rede Internet: https://www.mill-sbm.com/