Электронная почта: [email protected]

30Мобильная дробильная установка т/ч-200т/ч на продажу

Понимание мобильных дробильных установок

Так, что такое мобильная дробильная установка? Проще говоря, это портативная система, предназначенная для разрушения камней, руды, и стройматериалы прямо на месте работы. В отличие от стационарных дробильных установок, мобильные установки обеспечивают гибкость, эффективность, и экономия средств в центре внимания.

Типичная мобильная дробильная установка включает в себя:

- Загрузочный бункер

- Первичная дробилка (часто челюсть или удар)

- Вторичные/третичные дробилки (конус или удар)

- Скрининговая установка

- Конвейеры

- Силовой агрегат (генератор или двигатель)

С моделями производительностью от 30 т/ч до 200 т/ч. (и выше!), они предназначены для всего: от небольших проектов до крупномасштабной добычи полезных ископаемых..

Почему мобильное дробление в тренде?

Честно, Возможность быстро перемещать оборудование и менять способ работы существенно изменила способы обращения с камнями и минералами.. Вот почему людям нравится мобильная дробилка:

- Двигайтесь легко: Вы можете быстрее приступить к работе и быстро переключаться между сайтами..

- Снижение затрат на установку: Вам не придется тратить лишние деньги на большие строительные работы.

- Маленький размер: Они хорошо работают, даже если места мало или оно постоянно меняется..

- Многоступенчатое дробление/сортирование: Настраиваемые конфигурации в зависимости от материалов и окончательных размеров.

Работаете ли вы с такими камнями, как базальт, гранит, известняк, металлическая руда, или переработанные материалы, мобильная дробилка помогает вам идти в ногу с меняющимися потребностями работы.

Приложения: Кому нужна мобильная дробильная установка?

Мобильные дробилки предназначены не только для больших орудий в горнодобывающей промышленности. Они идеально подходят для:

- Горнодобывающие компании (руда, уголь, железо, медь, и т. д.)

- Карьерные работы

- Строительные компании (переработка бетона/асфальта)

- Подрядчики по сносу

- Производители нерудных материалов

Итог: Если вам нужна обработка горных пород, где важны гибкость и скорость, мобильное дробление идеально.

Как выбрать правильную емкость: 30т/ч–200т/ч?

Не совсем понимаю, что вообще означает «т/ч».? Это расшифровывается как «тонны в час» — производительность завода..

- Маленькие проекты (30т/ч-50т/ч): Переработка бетона, небольшие карьерные или демонстрационные работы

- Средние сайты (50т/ч-120т/ч): Большие материальные нагрузки, больше размеров продукта

- Крупные операции (120т/ч-200т/ч): Добыча, основное совокупное предложение

Кончик: Оцените свои ежедневные и ежемесячные производственные потребности, затем выберите модель, которая выдерживает пиковые нагрузки. Зачастую разумнее немного увеличить размер для большей гибкости..

Типы и конфигурации мобильных дробилок

Мобильные дробилки обычно бывают нескольких типов сердечников.:

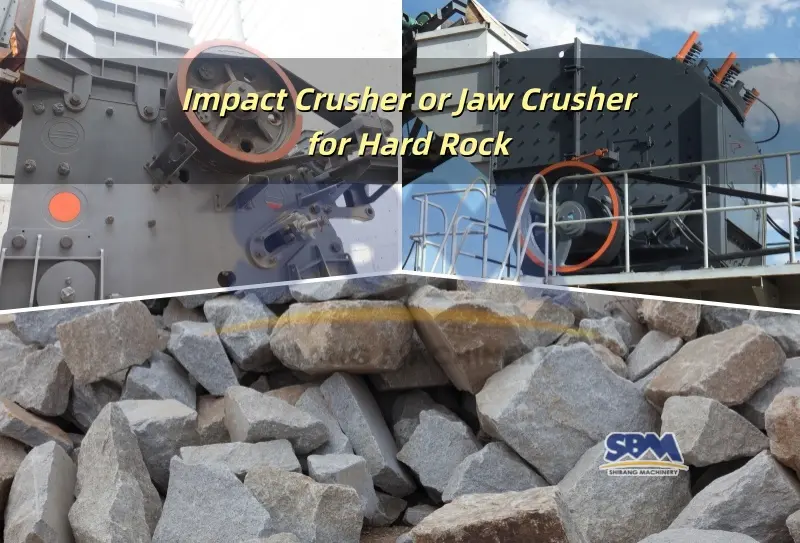

- Мобильная челюстная дробилка: Лучшее для жестких, большой камень как первый этап

- Мобильная конусная дробилка: Доставляет отлично, однородный конечный продукт, идеально подходит для вторичного/третичного дробления

- Мобильная ударная дробилка: Превосходно справляется с материалами от мягких до среднетвердых. (хорошо подходит для переработанного бетона)

- Мобильная сортировочная установка: Разделяет материалы по размерам для окончательного использования

Популярные конфигурации:

- Одноблочный (базовое дробление)

- Двухступенчатый (челюсть + конус или удар + экран): Расширить функциональность

- Трехступенчатый (челюсть, конус/удар, экран): Максимальная гибкость для совокупного производства

Стол: Быстрое сравнение типов дробилок

| Тип | Лучшее использование | Выходной размер | Мобильность |

|---|---|---|---|

| Зубодробилка, мордоворот | Первичное дробление | Большой | Отличный |

| конусная дробилка | Среднее/третичное | Средний/тонкий | Очень хороший |

| Ударная дробилка | Вторичная/переработка | Переменная/кубовидная | Хороший |

| Сортировочный завод | Окончательная сортировка | Регулируемый | Отличный |

Ключевые характеристики, которые вы должны знать

При покупке мобильной дробильной установки, эти характеристики имеют значение:

- Производственная мощность: 30т/ч-200т/ч (тонн в час)

- Размер подачи: Максимальный размер породы, которая может попасть в дробилку (например, до 900 мм)

- Размер экрана/деки: Определяет конечную градацию продукта

- Блок питания: Дизельный генератор или электрический, требуется кВт (например, 300–450кВт)

- Мобильность: Гусеничный или колесный; гидравлические ножки для легкой установки

- Вес/Размеры: Крайне важно для получения разрешений на транспортировку и перемещения между объектами.

- Автоматизация/Управление: Дистанционное управление, защита от перегрузки

Сравнение основных брендов (СБМ & Более)

Давайте соберем несколько реальных примеров и спецификаций.:

SBM K Series & Основные характеристики серии МК

Мобильная дробилка SBM предлагает модульные конструкции, быстрая установка, и оптимизированная производительность. Они охватывают процессы грубого и сверхтонкого дробления., производство песка, и скрининг, и широко используются для добычи полезных ископаемых, строительство, и переработка твердых отходов.

Популярные модели SBM (образцы спецификаций):

- Размер подачи: 0–900 мм

- Емкость: 50т/ч – 450т/ч

- Шасси: Универсальная рама; быстрое обновление, замена дробильного оборудования

- Моторная мощность: До 450кВт

- Функции: Каркас лодочного типа, регулируемые крылья, модульная сборка, пылеподавление

Сравнительная таблица: Готовые к выходу на рынок мобильные дробильные установки

| Модель | Емкость (т/ч) | Размер подачи (мм) | Власть (кВт) | Масса (т) | Главная дробилка | Скрининговые колоды |

|---|---|---|---|---|---|---|

| СБМ МК | 50–450 | 0–900 | до 450 | – | Челюсть/конус/удар | 1–3 |

| JC-3 | 250–300 | 1100 Икс 850 | 450 | 100 | Челюсть+Конус | 3 |

| ФТК-200-С | 100–200 | 185 | 300 | 46 | Конус | 1 |

| JC-2 | 120–150 | 900 Икс 650 | 315 | 80 | Челюсть+Конус | 3 |

Примечание: Для получения полной информации и местных характеристик, проверьте веб-сайты поставщиков или свяжитесь с производителями для получения рекомендаций для конкретного сайта..

Монтаж, Настраивать & Советы по техническому обслуживанию

Установить мобильную дробильную установку проще, чем когда-либо, но есть хитрости, как сделать это правильно:

- Позиция на конюшне, ровная площадка

- Убедитесь, что на площадке нет мусора и опасностей.

- Подключить коммунальные услуги: власть, вода (специально для пылеподавления)

- Осмотрите все защитные ограждения и аварийные системы.

- Перед началом тяжелого производства выполните полную проверку системы.

- Обучите операторов опасностям и средствам контроля, характерным для конкретной площадки.

Регулярное техническое обслуживание:

- Ежедневный осмотр ремней, экраны, и изнашиваемые детали дробилки

- Смажьте движущиеся части согласно рекомендациям.

- Контролируйте работу генератора или двигателя.

- Храните запасные части (ремни, экраны, лайнеры) под рукой, чтобы избежать простоев

Расходы, Инвестиции & Анализ рентабельности инвестиций

Давайте поговорим о том, что важно: ваш бюджет! Мобильные дробильные установки приносят прибыль за счет сокращения затрат на фундамент, ускорение настройки, и сокращение логистики. Но каждая модель различается.

Типичные инвестиционные диапазоны:

- 30т/ч–50 т/ч: Более низкая цена покупки, меньше мощности

- 100т/ч–150 т/ч: Более высокая стоимость, более крупные двигатели и модули экранирования

- До 200т/ч: Премиальные инвестиции, популярен для непрерывной добычи/карьерных работ

Факторы рентабельности инвестиций:

- Скорость установки: Сэкономьте дни/недели на строительных работах

- Транспортная гибкость: Перемещайтесь между сайтами по мере изменения контрактов

- Адаптивность производства: Быстро осваивайте новые материалы

Практические примеры

Случай: Кенийский базальтовый карьер

- Емкость: 200т/ч, основной блок челюсть+конус+экран

- Быстрая установка, обработка кормов переменного размера

- Увеличение годового объема производства, минимальное время простоя

- Обратная связь с оператором: «Автоматизация и скорость существенно изменили наше производство».

Часто задаваемые вопросы

Q.: Могут ли мобильные дробильные установки сравниться по производительности со стационарными установками??

А: Для большинства приложений, да. Современные портативные дробилки обеспечивают производительность и качество продукции, не уступающие стационарным установкам., добавляя при этом гибкость.

Q.: Нужны ли мне специальные разрешения на перемещение мобильных дробилок??

А: Грузчики должны проконсультироваться с местными транспортными властями., поскольку вес и размеры имеют значение.

Q.: Как мне выбрать между челюстью, конус, и модели воздействия?

А: Выберите челюсть для грубой обработки, основная работа; конус для штрафа, однородный агрегат; влияние на переработку и переменный размер продукции.

Сводный контрольный список для покупателей

Прежде чем купить, пробежаться по этому списку:

- Оценить потребности в производственных мощностях (тонн/час)

- Проверьте, какой материал вы будете измельчать (жесткость и содержание воды)

- Выберите нужную настройку (челюсть, конус, влияние, или экран)

- Подумайте, как вы будете перемещать машину и где она будет работать.

- Определите свой бюджет и посмотрите, как быстро машина окупит себя.

- Запросите послепродажное обслуживание, гарантия, обучение операторов

- Убедитесь, что установка может быть изменена или модернизирована в будущем.

Готов совершить прыжок? Обратитесь к производителям для идеального соответствия!

Почему стоит выбрать мобильную дробильную установку производительностью 30–200 т/ч?

Портативная дробилка — основа мобильной добычи полезных ископаемых, строительство, и разработка карьеров. С агрегатами, настроенными на надежность, адаптивность, и высочайший уровень производительности, ваш бизнес может развиваться быстрее, реагировать быстрее, и становись умнее. Инвестиции в мобильную дробильную установку означают, что вы обеспечите безопасность своей деятельности на долгие годы вперед.!

Хотите более глубокое погружение или индивидуальный совет? Сообщите мне о целях вашего проекта, предпочтительные материалы, или местоположение – и я помогу вам сузить выбор.