Электронная почта: [email protected]

Руководство по выбору челюсти: Оптимизируйте производительность для вашей операции

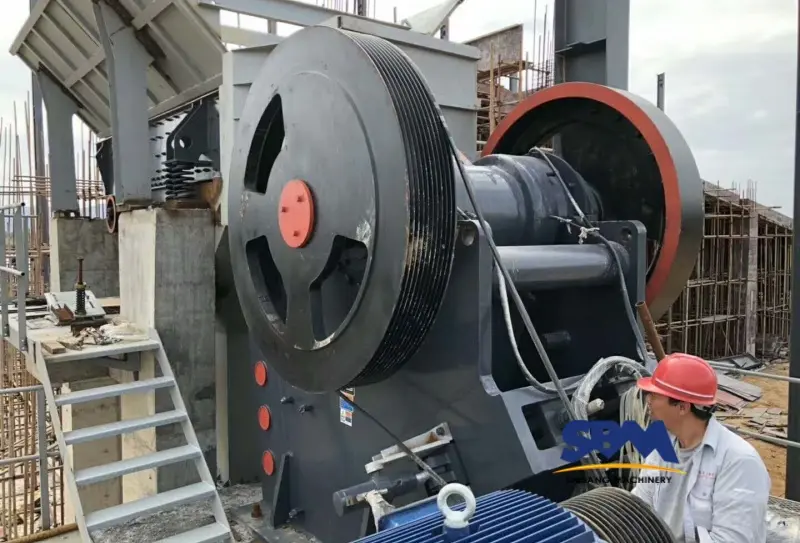

Choosing the right jaw plates can increase yourэффективность дробления к 25-40% при одновременном снижении затрат на замену. This comprehensivejaw plate selection guide explains how material composition, конструкция профиля зуба, и условия эксплуатации определяют долговечность пластины. Независимо от того, используете ли вы щековую дробилку C6X или более старые модели, these insights will help you make informed decisions.

Key Factors in Jaw Plate Selection

Material Composition Choices

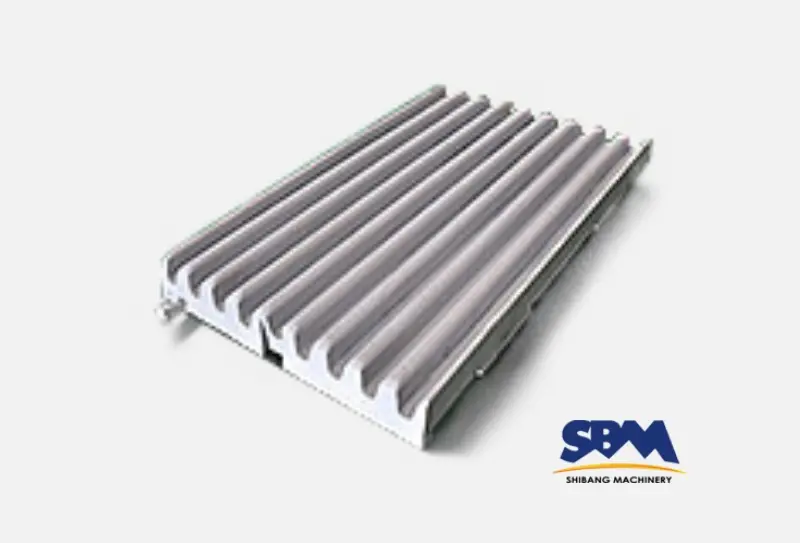

Modern jaw plates use three primary materials:

- Марганцевая сталь (14-18%): Ideal for general-purposequarry applications, withstands 50-70k tons before replacement

- Chrome Iron Alloy: 30% longer lifespan in abrasive materials like granite

- Ceramic-Enhanced: Reduces wear by 45% in high-silica content operations

Tooth Profile Design Considerations

The plate’s tooth configuration directly impacts yourcrusher’s working mechanism:

| Profile Type | Лучше всего для | Output Size Range |

|---|---|---|

| Straight | Первичное дробление | 150-300 мм |

| Waved | Secondary reduction | 50-120 мм |

| Гибридный | Mixed material feeds | 30-150 мм |

4-Step Selection Process

- Analyze Feed Material: Test hardness (шкала Мооса) and abrasiveness

- Determine Crusher Type: C6X series jaw crusher requires specific plate locking systems

- Calculate Economic Lifespan: Balance initial cost vs tons crushed/$

- Verify Compatibility: Check mounting system dimensions (±2mm tolerance)

Maintenance Synergy: Plates and Crusher Health

Properjaw crusher maintenance extends plate lifespan by 60%:

- Переворачивайте тарелки каждые 200-300 часы работы

- Maintain correct CSS settings (affects wear patterns)

- Use laser alignment tools for precise installation

Тематическое исследование: Granite Quarry Optimization

A Brazilian operation achieved 32% cost reduction by:

- Switching from standard Mn14 to Mn18Cr2 plates

- Implementing bi-weekly wear measurements

- Syncing replacements with scheduled maintenance downtime

Усовершенствованные методы мониторинга

- 3D wear scanning for precise remaining thickness analysis

- AI-powered wear rate prediction models

- Ultrasonic hardness testing for material verification

Common Selection Mistakes

- Choosing cheap plates needing 3x more frequent replacement

- Ignoring material compatibility (например, zinc contamination)

- Overlooking plate weight impacts on crusher kinematics

Strategic Selection Pays Dividends

Магистрвыбор челюсти requires understanding your material, Тип машины (like C6X models), and operational goals. Pair this guide with regular preventive maintenance to achieve 18-24 month plate lifespans even in demanding conditions. Помнить: The optimal plate today may differ tomorrow – re-evaluate selections with major material changes.