E-posta: satış@mill-sbm.com

Ezilmiş granit taş

Ev » Ezilmiş taş » Ezilmiş granit taş

Ana içerik

Ezilmiş granit taş dayanıklı bir, Araba yolları için çevre dostu agrega, peyzaj, ve inşaat. Üstün drenaj sunar, 100–250 MPa sıkıştırma mukavemeti, ve uygun maliyetli için çok yönlü boyutlandırma, kararlı yüzeyler.

Dayanıklı bir arıyorsanız, çok yönlü, ve bir sonraki projeniz için çevre dostu malzeme, ezilmiş granit taş sadece gitmenin yolu olabilir. Müşterilerimden tekrar tekrar duydum. Güven bana - gerçek bir fark yaratıyor! Bu kılavuz, bilmeniz gereken her şey hakkında ayrıntılara girecek: Uygulamalardan ve faydalardan boyutlandırma ipuçlarına kadar. Başlayalım.

Tam olarak ezilmiş granit taş nedir?

Ezilmiş Granit, mekanik olarak katı granitin açısal parçalara ayrılmasıyla yapılan doğal bir agregadır. Yuvarlak nehir çakılından farklı olarak, Sabit bir yüzey oluşturmak için pürüzlü kenarları bir araya geldi. Ezilmiş granit, ince bir tozdan boyutu (“yıpranmış granit”) Kaba parçalara. İlginç gerçek: Mineral bileşenleri granit (kuvars ve feldspat gibi) İmzalı benekli görünümünü ve olağanüstü dayanıklılığını verin.

Tepe 5 Granit agrega için kullanır

- Araba yolları & Yol: Sıkıştırılabilirliği, taban katmanları için ideal hale getirir.

- Peyzaj: Bahçe yolları için mükemmel, Verandalar, veya dekoratif zemin örtüsü.

- Yapı: Beton karışımlarında ve drenaj sistemlerinde kullanılır.

- Erozyon kontrolü: Eğimleri ve kıyı şeridini stabilize eder.

- Demiryolu balastı: Ağırlığı ve drenaj özellikleri nedeniyle parçaları destekler.

Bir keresinde çamurlu arka bahçem izimi değiştirdimgranit agrega—Zero yabani otlar ve her türlü hava durumu kullanılabilirliği!

Neden Ezilmiş Granit'i Seçin? Temel avantajlar

- dayanıklılık: Ayaktan ve ağır yüklere direnir (sıkıştırma mukavemeti: 100–250 MPa).

- Çevre dostu: 100% doğal ve geri dönüştürülebilir.

- Drenaj: Parçacıklar arasındaki boşluklar su havuzunu önler.

- Estetik çekicilik: Renk varyasyonları ile rustik cazibe (gri, pembe, veya altın).

- Uygun Maliyetli: Dostlardan veya katı levhalardan daha ucuz.

Popüler granit çakıl boyutları ve kullanımları

İşte eşleşecek hızlı bir referans tablosugranit taş agrega Projenizin boyutları:

| Boyut (mm) | Ortak isim | En iyisi |

|---|---|---|

| 0–5 | Ayrışmış granit | Yollar, oyun alanları, toprak değişikliği |

| 5–10 | İnce granit cipsleri | Araba yolları, dekoratif malç |

| 10–20 | Orta granit çakıl | Yol üssü, drenaj katmanları |

| 20–40 | Kaba granit kaya | Peyzaj aksanları, erozyon kontrolü |

Uç: Araba yolları için, Pürüzsüzlük için 20-40 mm'lik bir tabanı 5-10 mm'lik bir üst katmanla eşleştirin!

Kaliteli ezilmiş granit taş nasıl kaynaklanır?

Hepsiezilmiş granit eşit yaratıldı! Satın alırken:

- Dereceyi Kontrol Edin: Tek tip parçacık boyutlarından emin olun (Elek analiz raporları isteyin).

- Sertliği Doğrula: Granit tercih et >6 Mohs sertliği (SBM Çin’in Taşları gibi).

- Renk düşün: Projenizin estetiğini eşleştirin - E.G., Modern Bahçeler İçin Gri, Sıcak tonlar için pembe.

Bunun dışında, Manuel kırma veya çene kırıcıları da kullanabiliriz (kaba agregalar için) ve çekiç kırıcılar (ince agregalar için) Granit veya diğer cevherleri ezmek.

Kırmalar neden üstün ezilmiş granit taş sunar??

El kırıcının aksine, Mekanik kırıcılar sağlar:

✅Tutarlı parçacık boyutu (Sıkıştırma ve drenaj için kritik).

✅Açısal parçalar (birbirine geçme istikrarı).

✅Minimal toz/enkaz (Yerleşik ekranlar veya hava filtreleri aracılığıyla).

✅Ölçeklenebilir çıktı (ayrışmış granit tozundan 40mm yol tabanına kadar).

3 Her proje ölçeği için kırıcı türleri

| Tip | Proje ölçeği | Giriş | Çıktı | En iyisi | İpucu/Hack | Maliyet |

|---|---|---|---|---|---|---|

| Taşınabilir çene kırıcıları | Küçük-orta projeler | Çiğ granit kayalar (≤500mm) | Kaba toplama (10–40mm) | Yıkım atıklarının veya taş ocağı artıklarının yerinde geri dönüşümü | Ayrıntılara ayırt etmek için titreşimli ekran ekleyin (0–5mm) Yollar için | ~ 200 $/gün kiralayın (Araba yolları/peyzaj için ideal) |

| Koni kırıcılar | Orta büyük üretim | Önceden ezilmiş parçalar (≤150mm) | Muntazam orta çakıl (5–20mm) | Kesin derecelendirme gerektiren yüksek hacimli projeler (Örn., demiryolu balastı) | Silika maruziyetini azaltmak için toz bastırma sistemi ile eşleştirin | – |

| Etki kırıcılar | İnce agrega & Özel şekiller | Orta granit parçalar (≤100mm) | Kübik şekilli fişler (3–10mm) veya ayrışmış granit (0–5mm) | Pürüzsüz kenarlara ihtiyaç duyan dekoratif çakıl veya beton karışımları | – | – |

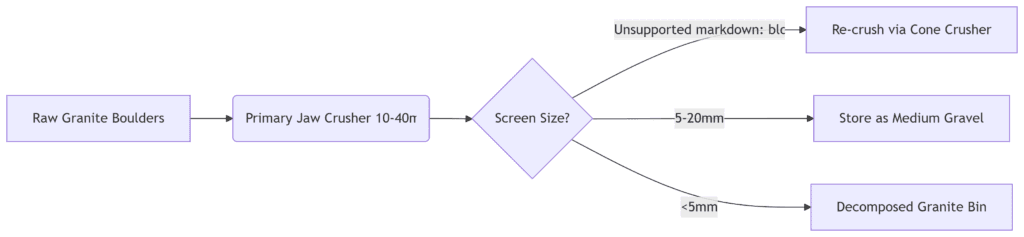

Kırıcı iş akışı: Çiğ kayadan premium agregaya

Optimal kalite için bu diziyi takip edin:

Not: Her zaman bir elek kiti ile çıktıyı test edin - eğer >15% Parçacıklar hedef boyutundan sapar.