E-posta: satış@mill-sbm.com

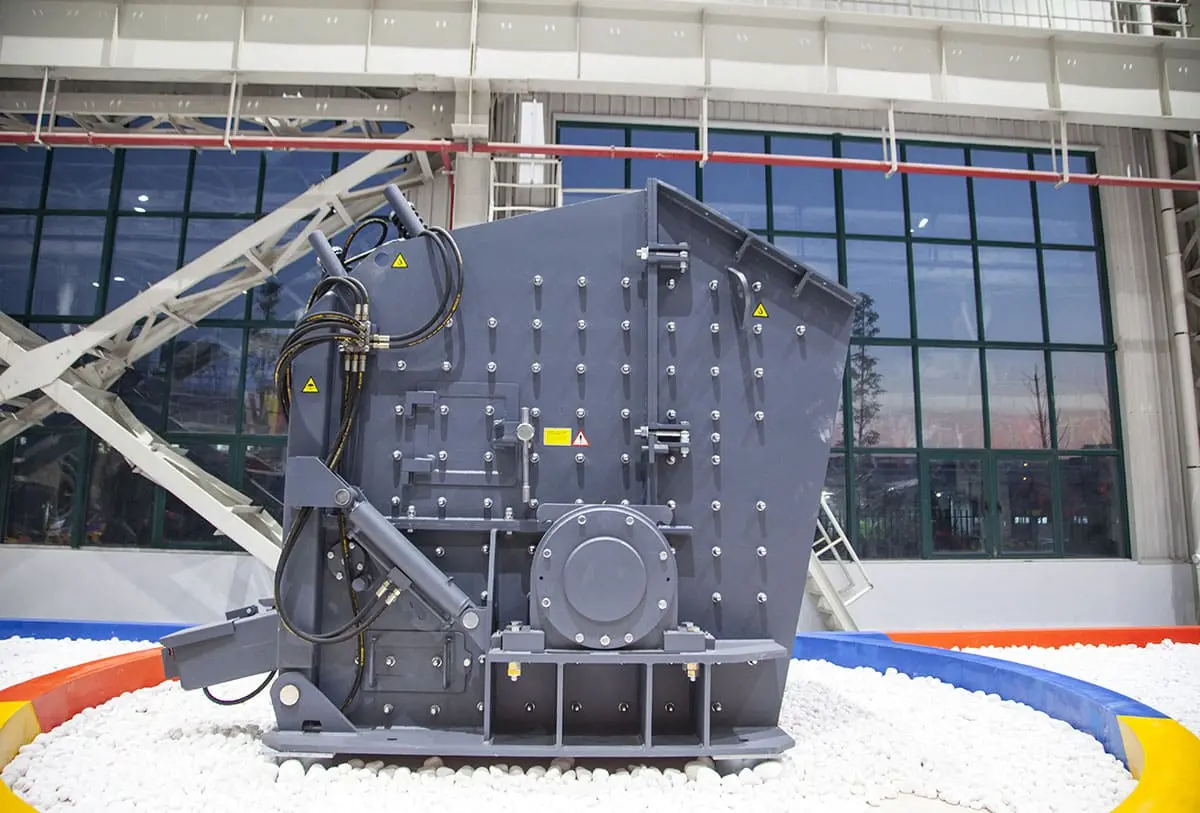

PFW Darbeli Kırıcı

PFW Darbeli Kırıcı (Olarak da bilinir “Avrupa Etki Kırıcısı”) esas olarak metalurjide kullanılır, bana ait, çimento, kimya mühendisliği, Yangına Dayanıklı Malzemeler, Seramik ve diğer endüstriler, yanı sıra otoyol yapısında, Su Koruma Projeleri, Agrega ve makine yapımı kum alanları, vesaire.

Ürün Özellikleri: Otomatik hidrolik kriko cihazının kullanımı kontrolleri ve bakımı kolaylaştırır ve işçilik maliyetlerini azaltır.

- Giriş Boyutu: 0-700mm

- Kapasite: 70-400TPH

- Malzeme: kireçtaşı, feldispat, kalsit, talk, barit, dolomit, kaolin, alçıtaşı, grafit, vesaire.

En İyi Teknoloji, Benzersiz tasarım

PFW Impact Crusher dünya standartlarında üretim teknolojilerini benimser. Üst düzey malzemelerden oluşur. Ağır hizmet tipi rotor tasarımı ve katı kontroller rotorun yüksek kaliteye sahip olmasını sağlar. Bu sırada, Benzersiz sabit cihaz, çekiç daha güvenilir hale getirir.

Dökme çelik yapı, Yüksek tutma kapasitesi

PFW Etkisi Kırıcı’ın Rulman Koltuğu entegre döküm çelik yapısı kullanır, kararlı işlem sağlar. Daha büyük yataklar daha yüksek tutma kapasitesine sahiptir.

Yarı otomatik operasyon bakımı kolay ve kullanışlı hale getirir

PFW darbe kırıcı hidrolik kontrol sistemini donatabilir. Hidrolik cihazla, deşarj açılışının boyutu ve boşaltma ayrıntı düzeyinde hızlı bir şekilde kontrol edilebilir. Ayrıca, Otomatik hidrolik kriko cihazı, çekiç gibi savunmasız parçaların hızlı bir şekilde değiştirilmesi için yararlıdır, böylece bakım kesintisi dolaylı olarak kısaltılabilir.

Basitleştirilmiş teknolojik süreç, Geniş uygulamalar

PFW darbe kırıcının iki boşluklu ezilmesi, kaba ve orta-coarse ezme teknolojik sürecini basitleştirebilirken, üç boşluklu ezme PFW Etki Etki Kırıcısının ince ve süperfinik ezme ile son derece iyi performans göstermesini sağlar. İki çeşit ezici boşluk kaba, kaba çoğunluğunu karşılayabilir, Orta ve ince ezici operasyonlar.

Dijitalleştirilmiş İşleme, Daha Yüksek Hassasiyet

Onlarca satır sayısal kontrollü takım tezgahı var. Çelik levhalar gibi işlemler’ kesme, bükme, planlama, frezeleme ve boya püskürtme işlemlerinin tümü sayısal olarak kontrol edilir. İşleme hassasiyeti yüksektir, özellikle çekirdek parçalar için.

Yeterli Yedek Parça Temini, Sorunsuz Çalışma

SBM, İşletmeleri üretim ve satışı kapsayan, Kendi ürettiğimiz her makinenin sorumluluğunu alır. Sorunsuz çalışmayı sağlamak için müşterilerimize ürünler ve orijinal yedek parçalar hakkında teknik hizmetler sunabiliriz..

Çalışma prensibi

PFW Etki Kırıcı Malzemeleri Etki Kuvvetleri ile Kırıyor. Malzemeler çekiçin çalışma alanına girdiğinde, Yüksek hızlı şok altında ezilebilir ve daha sonra başka bir ezme için rotorun üzerindeki darbe cihazına atılabilirler. Sonraki, Malzemeler astar plakasından çekiçin çalışma alanına sıçrama. Bu süreç, malzemeler nitelikli ayrıntı düzeyine ulaşana ve taburcu oluncaya kadar sürekli olarak tekrarlanır. Darbe rafı ile rotor rafı arasındaki boşluğun ayarlanması, bitmiş ürünlerin ayrıntı düzeyini ve şeklini değiştirebilir. Etki plakasının arkasında bir yay güvenlik cihazı var. Kırılmaz malzemeler kırma odasına girdiğinde, Kırıcıdan kırılamaz malzemeleri boşaltmak için darbe rafı geriye gider.

Ürün parametreleri

| Modeli | Rotor spesifik (mm) | Besleme açıklığı (mm) | Maksimum besleme boyutu (mm) | Kapasite(t/h) | Güç(kW) | Ortalama boyut (mm) |

| PFW1214Ⅲ | Ф1150 × 1400 | 570× 1430 | 250 | 90-170 | 132 | 2550× 2310 × 2100 |

| PFW1315Ⅲ | Ф1300 × 1500 | 625× 1530 | 300 | 180-270 | 200 | 2960× 2570 × 2380 |

| PFW1415ⅲ | Ф1400 × 1500 | 800× 1530 | 350 | 280-350 | 250-315 | 3120× 2650 × 2660 |

Not:

Modellerle ilgili ürün resimleri ve parametreler, veri, Bu web sitesindeki performanslar ve teknik özellikler yalnızca referans amaçlıdır. SBM'nin yukarıda belirtilen bilgiler üzerinde değişiklik yapma ihtimali vardır. Belirli mesajlar için, lütfen gerçek nesnelere ve kullanım kılavuzlarına bakın. Özel talimatlar olmadan, SBM bu web sitesinde yer alan tüm verileri açıklama hakkını saklı tutar.