E-mail: [email protected]

Cách điều chỉnh kích thước hạt xả của máy nghiền hàm?

How to adjust jaw crusher discharge particle size is key for any mining operation aiming for consistent product quality and high efficiency. Whether processing hard rock or softer minerals, tweaking this setting means better throughput and reduced waste—a win-win for every plant operator.

Why Discharge Particle Size Matters?

The size of the material coming out of the jaw crusher affects not only what goes onto the next machine, but also how well the rest of your process works. If the material is too big or not even, it can block screens, strain other crushers, and lead to batches being thrown out. Getting a steady and even size from the jaw crusher helps everything run smoothly, lets you get more good product, and keeps your costs under control. That’s why learning to adjust this setting properly is a valuable skill for anyone working in mineral processing.

Main Methods for Jaw Crusher Adjustment

Adjusting the discharge opening (also called crusher gap setting) controls output size. The methods vary by machine model and technology, but all have the same end goal: precise particle control.

Here are the industry’s main techniques:

- Mechanical Shim Stack Adjustment

- Wedge Block Adjustment

- Hydraulic Cylinder Adjustment

Each method suits different operational scenarios and budgets, so let’s explore each one with examples and practical tips.

Mechanical Shim Adjustment

The oldest, most affordable way to adjust jaw crusher discharge size is by changing the thickness of steel shims placed behind the crusher’s toggle plate. Here’s how it works:

- Stopping the crusher safely

- Loosening the tensioner bolts

- Adding or removing shim plates to change the gap

A thicker shim means a narrower discharge, delivering finer particles. Thinner shim stacks produce a wider gap, so you get coarser material.

Ưu điểm:

Low cost, đáng tin cậy, suits large primary crushers

Nhược điểm:

Thủ công, slow (giờ), not suited for frequent changes

Wedge Block Adjustment

Many modern machines use an adjustable wedge block system to alter the gap quickly. Operators can tighten or loosen bolts on wedge assemblies to move the crusher jaw forward or backward, precisely setting the discharge opening.

- Quicker than shims, around 30 phút

- Moderate accuracy, usually ±5–10mm

Ưu điểm:

Faster than shims, moderate flexibility

Nhược điểm:

Still requires stoppage for adjustment

Hydraulic Cylinder Adjustment

Modern jaw crushers often use hydraulic cylinders to make quick changes to the size of the discharge opening. With this setup, it’s easy to press a button or move a lever to shift the jaw, so you can adjust the output size right away—even while the machine is running.

- Adjustment range: wide, usually ±1–5mm

- This system works well for setups with several crushing stages, for tough materials, and for plants that handle large amounts of rock.

Ưu điểm:

Nhanh, chính xác, can be automated, an toàn hơn

Nhược điểm:

Chi phí cao hơn, needs skilled maintenance

Choosing Optimal Discharge Size for Your Application

Selecting the right jaw crusher output size depends on:

- What kind of material is being crushed (how hard it is, its size, and moisture level)

- What particle size is needed next (for further sorting or crushing)

- How much production and throughput are required

It’s smart to begin with advice from the equipment maker, then tweak the setting using real-world data and feedback from sample tests or lab screens.

Reference Product Parameters

For practical illustration, let’s look at Thể dục Và Máy nghiền hàm C6X models from SBM Industrial Technology Group (sbmchina.com):

| Người mẫu | Mở nguồn cấp dữ liệu (mm) | Discharge Setting Range (mm) | Dung tích (quần què) | Ứng dụng | Loại điều chỉnh |

|---|---|---|---|---|---|

| PE-600×900 | 600×900 | 65–160 | 50–180 | Trung bình, linh hoạt | Mechanical Shim |

| PE-900×1200 | 900×1200 | 95–165 | 220–380 | Large-scale primary | Mechanical Shim |

| C6X-160 | 1200×1600 | 150–300 | 600–2000 | Heavy duty, sản lượng cao | Xi lanh thủy lực |

Bảng so sánh: Adjustment Methods

The Role of Crusher Settings in Efficiency

Fine-tuning jaw crusher gap settings isn’t just about output size—it’s also about maximizing productivity and minimizing wear. Wider gaps speed up throughput but may let oversized particles pass, whereas narrower gaps produce finer output but can slow down the machinery. Operators should balance these factors for optimal performance.

Maintenance and Safety Tips

- Always stick to the manufacturer’s instructions.

- Check bolts and shims to make sure they’re not worn or broken.

- Grease all moving parts and adjustment systems, paying special attention to hydraulic cylinders.

- Use particle size measurement tools to keep track of results and reset settings when needed.

- Teach workers how to safely change the jaw opening to prevent accidents and avoid lost working time.

Common FAQs

MỘT: Change it anytime the feed changes, your products need a different size, or the jaw surface wears down.

MỘT: Hydraulic systems let you change the setting while the machine runs. Shim and wedge systems need the crusher stopped.

MỘT: Đúng. The right gap cuts down on extra crushing and saves power.

Phần kết luận

Learning how to set the jaw crusher’s particle size helps mining teams keep steady quality, increase output, and lower wear and downtime. Newer adjustment setups—from wedges to hydraulic cylinders—let operators match the output to any part of the process, whenever they need. For step-by-step help, check the equipment instructions or talk to experts.

Practical Advice

Look—adjusting a jaw crusher can feel technical, but after a few tries, it’s as routine as oil changes. Nhớ, a stable discharge size means happy customers, less headache, and more profit. If the spec sheet confuses you, don’t worry—reach out to SBM or give me a shout for tailored advice.

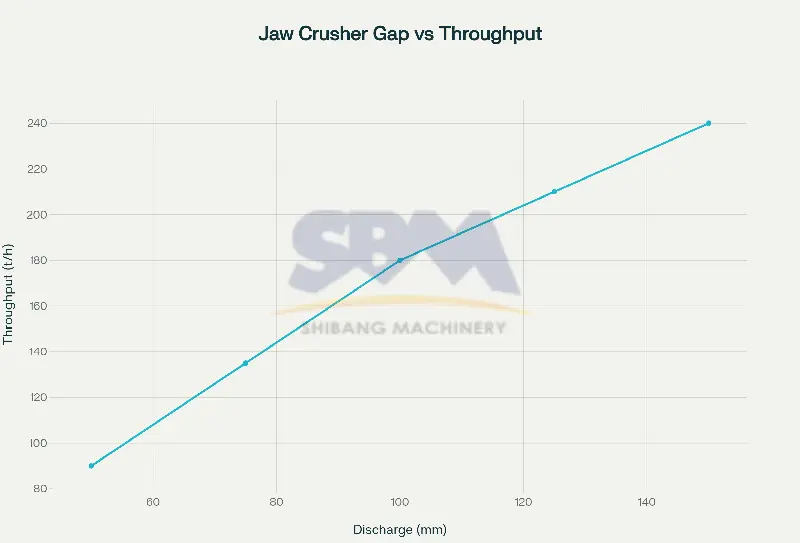

Chart: Particle Size Adjustment Impact on Throughput

- Adjustment Range: Narrower gap = finer output, but slower throughput

- Output Quality: Optimal setting = maximum saleable output, balanced wear and power use

Always aim for a discharge size that matches your downstream requirements, and keep those crushers in top shape for years of productive operation.