E-mail: [email protected]

Các bộ phận của máy nghiền hàm là gì?

Máy nghiền hàm là công cụ tuyệt vời để khai thác, tổng hợp, và các ngành xây dựng. Hiểu rõ các bộ phận chính của máy nghiền hàm giúp người mua đầu tư thông minh, tối đa hóa thời gian hoạt động, kiểm soát chi phí, và tối ưu hóa nhiệm vụ bảo trì. Hãy chia nhỏ từng phần quan trọng, with practical examples for buyers.

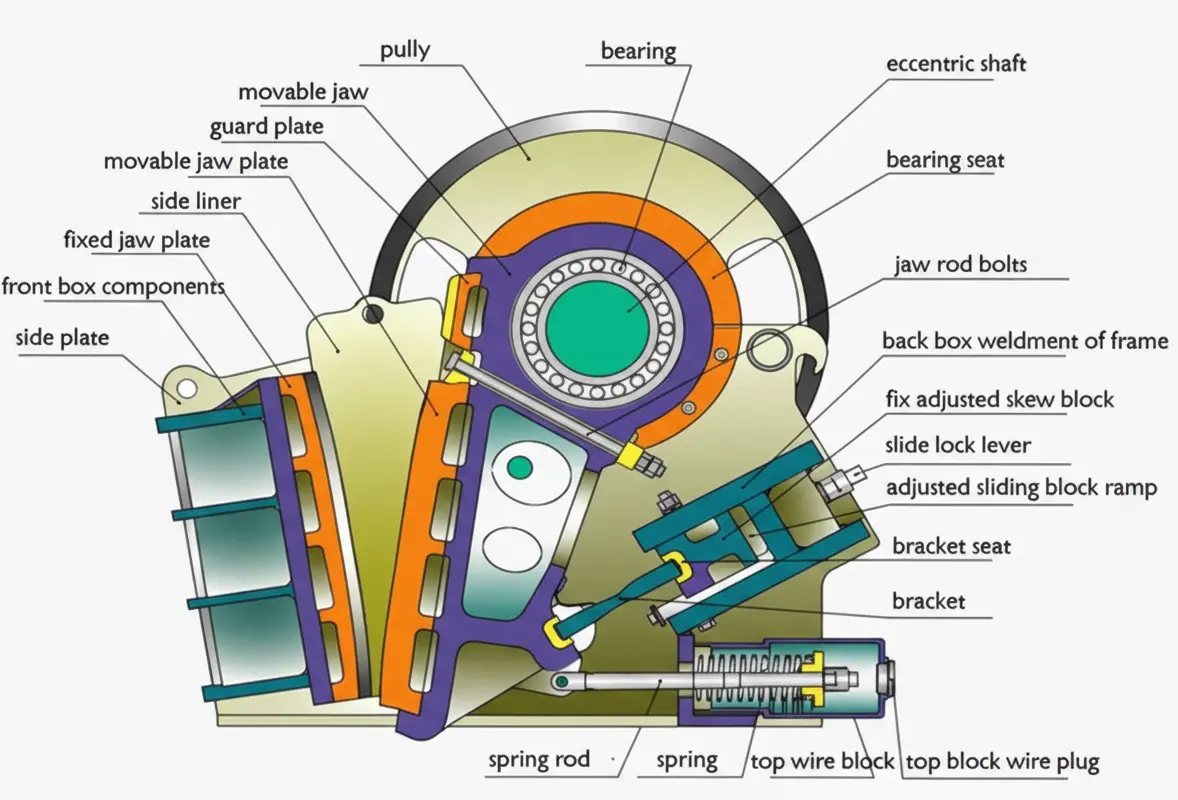

Jaw Crusher Parts Overview

A jaw crusher consists of several core parts with distinct locations and functions. Here’s a quick summary table before deep-diving into each part.

| Part Name | Vị trí | Role/Function | Main Material | Khoảng giá |

|---|---|---|---|---|

| tấm hàm | Đã sửa & hàm di chuyển | Crushing surface | Manganese steel | $200–$3,000/pc |

| Cheek Plate | Sides of jaw chamber | Protect side walls | Manganese steel, alloys | $100–$1,000/pc |

| Trục lệch tâm | Trung tâm, runs lengthwise | Drives jaw movement | High-carbon steel | $350–$2,500/pc |

| Crusher Body/Frame | Entire base | Structural support | Cast iron, Thép, alloys | $1,000–$12,000 |

| Bánh đà | Sides, outside chamber | Powers jaw movement | Cast iron, Thép | $500–$3,000/pc |

| Chuyển đổi tấm | Under jaw plates | Sự an toàn & jaw force transfer | Thép, alloys | $180–$800/pc |

| Pitman/Rocker | Connects jaw/shaft | Moves jaw, transmits force | Thép | $400–$2,000/pc |

| Vòng bi | Supports shaft/jaw | Enables rotation/movement | Alloy steel, vòng bi | $120–$1,200/pc |

| Guard Plate | Below plates | Protects moving jaw base | Thép, alloys | $80–$400/pc |

| Adjustment Block | At discharge | Controls output size | Thép, alloy | $150–$900/pc |

| Spring/Tension Rod | Under toggle | Maintains toggle pressure | Alloy steel | $60–$400/pc |

| Hệ thống thủy lực | Máy nghiền hiện đại | Adjusts CSS/safety features | Thép, hydraulic parts | $1,000–$6,000/kit |

| Băng chuyền | Output section | Material transport | Rubber/fiber steel | $300–$2,000/entry |

| Phễu thức ăn | Entry | Holds incoming material | Thép, alloy | $400–$2,500/pc |

| Motor | Power section | Drives movement | Electric/gas motor | $600–$5,000/unit |

Đĩa hàm

Position and Function

Jaw plates are the most important part of a jaw crusher. One plate stays still and is fixed to the body. The other plate moves, and it is attached to the pitman, swinging back and forth thanks to the shaft. When rocks or other material go in, the plates press together and break them up.

Material and Location

Most jaw plates are made from tough manganese steel or mixes of metals. You can find them on the main crushing surface inside the machine. Some jaw plates use special materials that last longer.

Pricing and Availability

How much jaw plates cost depends on the manufacturer, how thick they are, how much manganese they contain, and the shape. Thường xuyên, each plate costs from $200 ĐẾN $3,000, and more advanced designs are more expensive.

Insider Tip

Checking your jaw plates often and changing them at the right time helps your crusher work better and last longer.

Tấm má

Position and Function

Cheek plates are bolted on the sides of the crushing chamber, protecting the machine walls from abrasion as rocks move inside.

Material and Location

Produced from wear-resistant manganese steel or special alloys, cheek plates prolong the machine’s lifespan and reduce frame damage.

Pricing and Market

Cheek plates cost $100 ĐẾN $1,000 each, depending on size and alloy grade.

Quick Note

Replace cheek plates together with jaw plates for best performance and even wear.

Trục lệch tâm

Position and Function

Running through the pitman, the eccentric shaft drives the oscillation of the movable jaw. It converts rotational energy into linear movement, creating the “chewing” motion that crushes rock and ore.

Material and Design

Constructed from high-carbon or alloy steel for strength and torque resistance. The shaft end connects to the flywheel and motor.

giá cả

Market pricing ranges from $350–$2,500, largely based on shaft diameter and steel grade.

Crusher Body/Frame

Position and Purpose

This is the foundational shell—supporting all other jaw crusher parts and enduring the crushing pressure. Located around every working component.

Material Types

Frames are built from cast iron, carbon steel, alloy steel, or highly wear-resistant heavy steel plates, often with composite reinforcement.

Pricing Clues

Crusher frames are expensive, ranging from $1,000 ĐẾN $12,000 depending on size. That’s why steel grade and design matter so much for buyers.

Bánh đà

Location and Purpose

The flywheel is attached to the outside of the eccentric shaft. It stores spinning energy, helping the jaw move smoothly and keeping the crusher running at a steady speed.

Material Used

Usually cast iron or forged steel, with precision balancing for operational stability.

Market Pricing

Flywheels generally cost $500–$3,000 each, contingent upon diameter and material quality.

Chuyển đổi tấm

Function and Place

Acting as a safety mechanisms beneath the jaw plates, toggle plates transfer force and break under extreme stress, preventing more expensive damage.

Material Selection

Prime choices are alloy steels and precision-cast metals.

Market Pricing

Toggle plates can vary from $180 to $800/piece, reflecting material and design complexity.

Pitman (Rocker)

Position and Function

The pitman, also called the rocker, connects the moving jaw with the shaft and passes on the force needed to crush material. It handles strong pressure, so it needs to be made tough and well-built.

Vật liệu

Manufactured mainly from premium alloy or carbon steel.

Market Pricing

Ranges from $400–$2,000 depending on mass and alloy.

Buyer’s Tip

Increased pitman weight can boost crushing force, but also raises price and input power demands.

Vòng bi

Position and Function

Bearings support the eccentric shaft and movable jaw, providing smooth rotation and reducing friction. High-quality bearings mean longer equipment life.

Material Choices

Ideal bearings are made from hardened alloy steel, with advanced seals for dust and moisture protection.

Pricing Trends

Expect $120 ĐẾN $1,000+ per bearing, largely impacted by diameter, thương hiệu, and seal technology.

Guard Plates

Function and Placement

Mounted below the moveable jaw base, the guard plate prevents large debris from clogging critical moving parts.

Material Choice

Typically steel or alloy, sometimes reinforced for added wear resistance.

Khoảng giá

$80–$400 per piece.

Adjustment Block/Setting System

Position and Purpose

The adjustment block controls how far apart the jaws are, which changes the size of the material coming out. Simple adjustment systems make it faster and easier to fix or set up the crusher.

Nguyên vật liệu

Usually steel, sometimes alloy-reinforced.

giá cả

$150–$900 per adjustment block, higher if hydraulic or automated.

Springs and Tension Rods

Location and Function

Located below or beside toggle plates, springs maintain proper jaw tension and support toggle safety action.

Nguyên vật liệu

Alloy or hardened carbon steel.

Typical Market Price

Ranges from $60 ĐẾN $400 per assembly.

Hệ thống thủy lực (Modern Crushers)

Position and Function

Newest generations feature hydraulic systems for CSS adjustment, bảo vệ quá tải, and jam clearing—located near toggle mechanism.

Material Scope

Steel hydraulic cylinders, dòng, and electronic controls.

Price Estimate

Hydraulic kits run $1,000–$6,000, depending on scope and brand.

Conveyor Belt and Feed Hopper

Location and Function

Feed hoppers reside at the entry, guiding raw material into the crusher. Conveyor belts sit on the output side, moving processed material onward.

Material and Pricing

Hoppers are heavy steel or alloy, $400–$2,500. Conveyor belts range $300–$2,000 per line.

Động cơ

Function and Placement

The motor is connected to the shaft and flywheel. It gives the power needed to make the crusher move.

Type/Material

Electric or gas-powered, using copper windings, cast housings.

giá cả

Motors cost $600–$5,000 per unit depending on HP and brand.

Jaw Crusher Part Materials Comparison

| Phần | Main Material | Điểm mạnh | Tuổi thọ |

|---|---|---|---|

| tấm hàm | Manganese steel | mài mòn, impact resistance | High |

| Cheek Plate | Manganese steel, alloys | Mặc, shock protection | Cao |

| Frame/Body | Cast iron, Thép, alloys | Deformation, stress resistance | Rất cao |

| Shaft | High-carbon steel | Bend, torque resistance | Cao |

| Bánh đà | Cast iron, Thép | Sự ổn định, inertia | Cao |

| Vòng bi | Alloy steel, sealed | Friction, wear resistance | Cao |

| Chuyển đổi tấm | Thép, precision-cast | Bảo vệ quá tải | Med-High |

Jaw Crusher Prices & Value Factors

How much máy nghiền hàm and their parts cost can change because of several things:

- The type of materials used (better steel, metal mixes, or special parts will make prices higher).

- The brand (famous brands usually cost more, but often give better guarantees and customer service).

- The size and how much the crusher can handle (bigger machines or those that can crush more every hour are usually pricier).

- Extra features (things like hydraulic systems, automatic oiling, or special feeders can add to the cost).

- The market (things like demand, vị trí, delivery costs, and help after you buy can cause prices to go up or down).

Example Specification Table

| Người mẫu | Kích thước nguồn cấp dữ liệu tối đa (mm) | Phạm vi xả (mm) | Mở nguồn cấp dữ liệu (mm) | Quyền lực (kw) | Dung tích (quần què) | Cân nặng (t) |

|---|---|---|---|---|---|---|

| PE-250×400 | 210 | 20–60 | 250×400 | 15 | 5–20 | 2.8 |

| PE-600×900 | 500 | 65–160 | 600×900 | 55–75 | 70–150 | 15.5 |

| PE-1200×1500 | 1020 | 150–300 | 1200×1500 | 160–220 | 400–1000 | 100.9 |

BẢO TRÌ & Longevity Tips

Check your jaw plates, vòng bi, tấm chuyển đổi, thắt lưng, and guards every day or week to help your crusher last longer. Add oil to the bearings, look for cracks or worn parts, and make sure the jaw plates are lined up right. Run routine inspection checklist — most failures result from neglected maintenance of jaw crusher.

Buyer’s Practical Checklist

- Pick jaw plates and cheek plates made with the right kind of manganese to make them last longer.

- When looking at prices, remember to think about available spare parts, warranties, and after-sales help.

- Choose brands you see on trusted websites like SBMChina—they have good quality and real technical details.

- Using better materials and modern parts like hydraulic systems costs a bit more, but it saves money in the long run and makes fixing the crusher simpler.

- Keep a record of part numbers and replacements, so you can fix things faster if the crusher stops working.

Phần kết luận

Knowing the names, roles, materials, and price ranges of bộ phận máy nghiền hàm helps buyers make smarter choices, get better value, and avoid equipment problems. Buy from trusted companies, focus on good maintenance, and double-check part details often. If you want advice on picking the right crusher model, details, or a quote, just ask—then you can buy with confidence.