E-mail: [email protected]

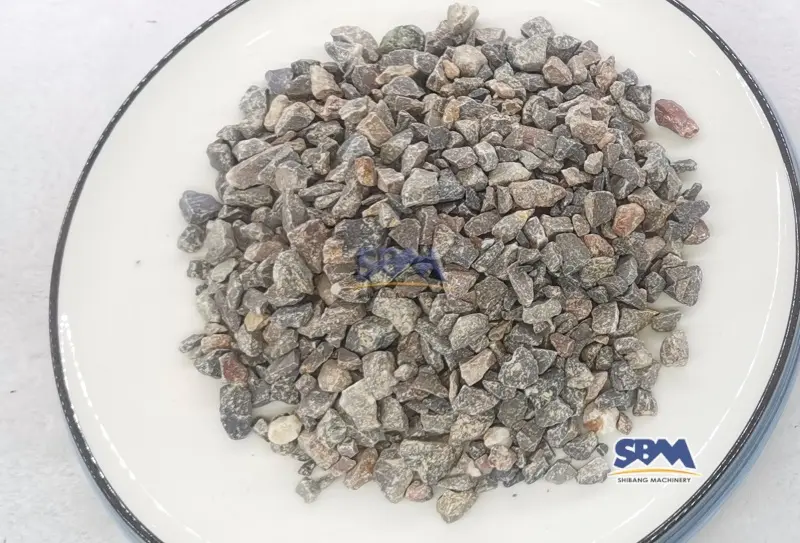

Chip đá vôi

Nội dung chính

Alright, let’s talk about limestone chip. It might not be glamorous, but let me tell you, after decades in the crushing equipment game, I’ve seen this stuff hold up highways, make concrete that lasts generations, and even turn sour, tired farmland into something productive again. It’s the unsung hero, the gritty foundation of… well, pretty much everything. Forget fancy jargon for a second – this is about the real rock work that makes progress happen. Let’s break down what makes crushed limestone tick, where it shines, and crucially, how to produce the good stuff without breaking the bank (or your equipment!).

Vì thế, What’s the Big Deal About Limestone Chips?

Đơn giản. You take chunks of limestone – that greyish-white rock full of calcium carbonate – and you bust it up into specific sizes. Sounds basic, Phải? But that’s where the magic lies. That composition gives it toughness, a knack for neutralizing acids, and the ability to play well in a ton of different scenarios.

Where You’ll Find It Working Hard?

Keeping Us Moving & Sheltered (Sự thi công)

- Concrete’s Best Friend: Seriously, try making decent concrete without quality aggregate like crushed limestone. It’s the bulk, the backbone, the thing that gives it strength to stand tall. Good limestone aggregate isn’t optional; it’s essential.

- Roads You Can Rely On: That smooth drive? Thank the layers of limestone chip underneath the asphalt acting as a solid, draining base. It’s also in the asphalt mix itself.

- Foundations That Don’t Sink: Before they pour that slab or build that wall, tonnes of crushed rock go in as stable fill and base. Sleep easy knowing it’s down there.

- Keeping Trains on Track: Railroad ballast? That’s angular limestone chips doing its thing – locking together, draining water, and holding those tracks steady. It’s a tough job, and this rock handles it.

Feeding the World (Nông nghiệp)

- Sweetening the Soil (Ag-Lime): This one’s personal. Seeing farmers spread finely ground limestone and watching lifeless, acidic fields slowly turn green and productive… that never gets old. It unlocks nutrients the soil was hoarding. Basic chemistry, massive impact.

- Strong Bones, Strong Shells: Ever wonder how chickens lay eggs with sturdy shells? Or how livestock builds strong bones? A sprinkle of ground limestone in their feed delivers that essential calcium. Đơn giản, hiệu quả.

Powering Industry & Keeping Things Clean

- Scrubbing the Skies (FGD): Power plants use limestone chip to capture nasty sulfur dioxide before it hits the air. It’s dirty work, but this rock helps keep our air cleaner. That’s something to be proud of supplying.

- The Hidden Ingredient: Cement, thủy tinh, Thép, even paper and paint – crushed limestone is a key raw material hiding in plain sight. It’s everywhere in the stuff we make.

- Clean Water Matters: Municipalities and factories use it to adjust water pH and pull out impurities. Clean water starts with good rock.

The Everyday Stuff

- đường lái xe & Paths That Last: A well-laid driveway of limestone chips gravel? Affordable, drains like a dream, and looks tidy. It’s practical.

- Sprucing Up the Yard: Those decorative limestone chips in gardens and pathways? Looks goodVà helps with drainage.

- Protecting the Pipes: Underground utilities? They get a protective bed of limestone chip to cushion and drain. Out of sight, but vital.

Bàn 1: Your Go-To Guide: Crushed Limestone Sizes & What They Do Best

| What We Call It | Rock Size (Approx.) | Where It Earns Its Keep | Why It Works |

|---|---|---|---|

| #8 / Pea Gravel | Pea-sized (3/8″ down) | Pretty paths, garden edges, cushioning pipes | Smooth, drains fast, easy on feet |

| #57 | Marble to Golf Ball (1″ down) | Concrete mixes, nhựa đường, French drains, general drainage | Locks tight, drains well, workhorse |

| #4 / #467 | Small Fist (1.5″ down) | Heavy-duty road base, big drainage jobs, slab prep | Bigger chunks, serious structure |

| #2 / #3 | Baseball to Softball (3″ down) | Armoring slopes, mega road bases, railroad ballast | Biggest rocks, brute force stability |

| Ag-Lime | Powder / Bụi | Fixing sour soil (raises pH) | Super fine, reacts fast with soil |

| Tiền phạt / Screenings | Cát / Grit | Locking pavers in place, firming paths, winter grit | Packs solid, stabilizes, fills gaps |

From Big Rock to Useful Stuff: How It’s Really Made

Making consistent, high-quality crushed limestone isn’t just smashing rocks. It’s a careful dance. Here’s how it usually plays out on the ground:

Making the First Break (Drill & Blast)

Deep holes, carefully placed explosives. Boom. Turns massive bedrock into haulable boulders. Safety and minimizing waste rock areeverything here – get this wrong, and you’re playing catch-up all day.

Hauling the Load

Big loaders, bigger trucks. Getting that blasted rock efficiently to the primary crusher eats up cost if you’re not careful. Fuel and time add up fast.

The First Crunch (Nghiền chính)

This is where the muscle shows up. Jaw crushers or big gyratories take boulders the size of small cars and turn them into manageable chunks (nghĩ 6-12 inch). You needseriously tough limestone crushing gear here. It takes a beating.

Getting Closer (Thứ cấp nghiền nát)

Cone crushers or impactors take the primary-crushed rock down further (nghĩ 1/2 inch to 4 inch). Need nice, cubical rock for concrete? MỘT good cone crusher is your best bet. They shape the rock well.

The Finishing Touch (Tertiary Crushing – Sometimes)

Want really fine stuff like concrete sand? Might need a third stage – often a cone crusher dialed in tight or a Vertical Shaft Impactor (MỌI NGƯỜI). VSIs are wizards for shaping and making specific sands. Finesse work.

Sorting it Out (Sàng lọc)

After each crush, the mix hits vibrating screens. It’s like a giant sifter, sorting the rock into the exact sizes customers need (like the ones in the table above). Oversized? Back to the crusher. Right size? Off to the pile. Mess up screening, and your product is junk. Simple as that.

Getting Clean (Rửa – Optional)

If you need super clean rock, especially sand for concrete or where dirt/clay is a problem, you wash it. Log washers or sand screws scrub it down. Adds cost, but sometimes you gotta do it.

Stockpiling & Vận chuyển

Good rock deserves good storage. Stockpile by size, keep it clean, load it fast onto trucks or trains. Organized piles mean happy customers and efficient loading.

Picking Your Rock Breakers: Don’t Guess, Get the Right Tool

Honestly, this is where I see too many operations stumble. Choosinglimestone crushing machines isn’t picking the biggest or cheapest. It’s matching the tool to the job. Think about:

- What are you feeding it? Huge boulders? Smaller quarry run?

- What do youneed to make? Mostly base rock? High-quality concrete stone? Tiền phạt?

- How much rock per hour? Gotta keep up with demand.

- Does shape matter? Cubical rock for strong concrete is different from base material.

- Staying put or moving around? Fixed plant or mobile setup?

- The Real Cost: Buying price matters, but what about power bills? How often do you replace wear parts? Cheap upfront can cost dearly later.

Bàn 2: Crusher Smackdown: Picking the Right Warrior for Limestone

| The Crusher | Where It Fights | Likes to Eat This Size | Spits Out This Size | Why We Like It | Things to Watch Out For | Best For Making… |

|---|---|---|---|---|---|---|

| máy nghiền hàm | First Round | Giant Boulders (48″+) | Big Chunks (6-12″) | Tough as nails, simple, handles the monster rocks | Rock shape isn’t always pretty, can make more fines | Base rock, big fill, ballast |

| Máy nghiền Gyratory | First Round (Big Mines) | Massive Boulders | Big Chunks (6-14″) | Huge appetite, keeps chugging | Pricey, complex, needs a permanent home | Giant quarry primary work |

| Máy nghiền hình nón | Second/Third Round | Fist-sized (6-12″) | Gravel to Small Rock (3/8″-4″) | Makesbeautiful cubical rock, great size control | Wear parts cost more, hates metal (uncrushables) | Concrete/Asphalt rock, chips |

| máy nghiền tác động (HSI/VSI) | Second/Third/Fines | Up to 24″ (HSI), Smaller (MỌI NGƯỜI) | Sand to Rock (Fines to 2″) | Super reduction, shapes rock nicely (MỌI NGƯỜI!), makes sand | Wear partsThực ra cost on abrasive rock, hates wet/clay, dusty | Manufactured sand, shaped rock, fines |

| máy nghiền cuộn | Second/Fines | Up to 6″ | Fines to 1″ | Gentle crushing, compact, less fines | Not for huge volumes long-term on hard rock | Getting towards Ag-Lime powder |

Why Getting Crushing Right Keeps You in Business?

Look, I’ve walked through plants where the crushing setup was an afterthought. It hurts to see. Bad crushing means:

- Your Power Meter Spins Like a Top: Wrong crusher, wrong settings = wasted electricity. Money flying out the window.

- Your Wear Parts Budget Explodes: đá vôi is abrasive. Put the wrong crusher on it, or run it poorly, and you’ll be changing mantles, concaves, and blow bars constantly. We build ours tough because we know the abuse they take.

- Your Product Looks Sad (and Performs Worse): Wonky shaped rock or bad sizing? Your concrete gets weaker, your asphalt doesn’t bind right, your drainage clogs. Customers notice. Fast.

- You Throw Away Good Rock: Too many fines you can’t sell? Too much oversized stuff needing recrushed? That’s profit literally going back through the crusher.

- You’re Always Fixing Something: Breakdowns. Adjustments. Downtime kills margins stone-cold dead. Reliability isn’t a luxury; it’s survival.

Investing in well-built, properly sized limestone crushing equipment – like the stuff from SBM that I’ve seen chew through tough rock day in, day out – isn’t just buying a machine. It’s buying peace of mind. Ts buying consistent product your customers want. It’s buying lower operating costs. It’s buyingprofitability. That’s the bottom line.

Making Top-Notch Limestone Chip: It’s More Than Just the Crusher

Want to be the quarry everyone wants to buy from? Crushing is crucial, but it’s only part of the story:

- Know Your Rock: Before you even start, understand the limestone deposit. Is it hard? Soft? Full of clay seams? (Looking at you, LA Abrasion value!). This tells you how hard it’ll be on equipment and if you need extra washing. Geology 101 pays off.

- Feed it Steady: Dumping a random mix of huge boulders and fine dirt into your primary crusher is asking for trouble. Scalping (pre-screening) takes out the fines and small stuff that chokes crushers and clogs conveyors. Seems obvious? You’d be surprised how often it’s skipped, causing chaos downstream.

- Screen Like Your Business Depends On It (It Does): Worn screen panels? Wrong mesh size? Screens not shaking right? Boom – off-spec product. Customerssẽ call. And they won’t be happy. Good screening is your quality control gatekeeper.

- Move Rock Smoothly: Conveyors that jam, transfer points that spew dust like a volcano, messy stockpiles that mix sizes… it screams amateur hour. Design the flow to be smooth and clean. Dust clouds and rock piles on the ground are money lost and safety hazards.

- Tame the Dust: Crushing limestone makes dust. Lots of it. Ignore this, and you’ll have angry neighbors, unhappy workers, and environmental fines. Water sprays, proper enclosures, baghouses – use them. It’s non-negotiable for responsible operation.

- Test, Test, Test: Don’t assume. Regularly check your product: Is the size right (sieve it!)? Is the shape good enough? Are the fines clean (sand equivalent test)? For Ag-Lime or FGD rock, check the chemistry! Consistent quality builds trust.

What’s Next? Smarter, Greener Rock Crushing

This industry isn’t standing still. Here’s what we’re seeing the sharp operators focus on:

- Doing More with Less (Sustainability): Cutting energy use per tonne (smarter drives, efficient motors), sử dụngevery bit of rock (minimize waste, find uses for fines), controlling dust fiercely, recycling wash water, and putting quarried land back to good use. It’s good businessVà good PR.

- Crushing on the Move (Tính cơ động): Mobile and modular plants aren’t just for small jobs anymore. They’re surprisingly efficient, flexible, and perfect for contract crushing or tricky sites. Seeing a well-run mobile setup producing quality rock is impressive.

- Letting Tech Help (Automation): Monitoring crusher settings and power draw remotely? Getting alerts before something breaks? Automating adjustments for optimal performance? It’s happening. Saves labor, boosts uptime, and optimizes output. Less guesswork, more rock.

- The Rise of Manufactured Sand (M-Sand): Natural sand sources are getting tapped out or restricted. Making high-quality sand from limestone chip fines (using VSIs) is becoming huge for concrete. It’s a growth market.

The Right Partner for the Rock: Why Your Gear Choice Makes or Breaks You

After years in this field, one thing is crystal clear: Your choice oflimestone crushing equipment is make-or-break. It decides:

- Your Profit: Through operating costs, yield, and maintenance bills.

- Your Reputation: By the quality of rock you ship out the gate.

- Your Sanity: By how often you’re fixing things instead of running.

- Your Right to Operate: By how cleanly and efficiently you do it.

Ready to Make Your Limestone Chips Operation Hum?

Turning raw limestone into the versatile, essential aggregate that builds our world is challenging, demanding, but honestly, incredibly satisfying. By truly understanding its value, mastering the production grind, and most importantly, partnering with the rightlimestone crushing equipment supplier, you build more than just piles of rock. You build a resilient, profitable business that stands the test of time. That’s the rock-solid foundation worth investing in.

Cut the frustration and boost your bottom line. See how SBM China’s heavy-duty jaw crushers, precision cone crushers, versatile impactors, and efficient complete plants are engineered specifically for the demands of limestone crushing. Get the reliability and performance your operation deserves. Check out the solutions athttps://www.mill-sbm.com – let’s crush your goals together.