E-pos: [email protected]

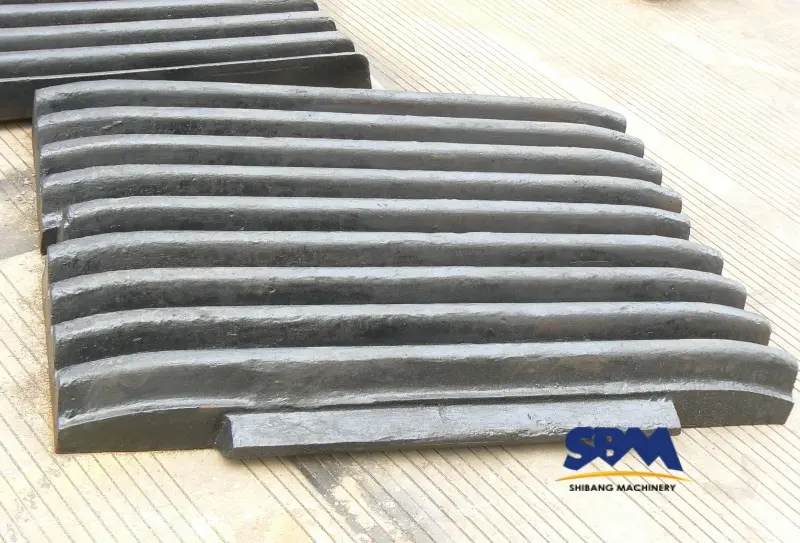

Stap-vir-stap-gids vir die vervanging van kakebeenvoerings: 8 Sleutelfases

Behoorlik Vervanging van kakebeenvoering verhoog die produksiedoeltreffendheid deur 40% en verleng die komponentlewe deur 2-3 jare. Hierdie uitgebreide gids bevat professionele tegnieke wat in gebruik wordKlein en groot mynboubedrywighede, Dekking van veiligheidsprotokolle, Gereedskapvereistes, en presisie -belyningsmetodes. Volg ons 8-fase-proses om stilstand tot onder te verminder 4 ure per vervanging.

Voorvervangingsvoorbereiding

1. Veiligheidsuitsluitingsprosedure

- Ontkoppel die kragtoevoer en betrek meganiese uitsluiting

- Los hidrouliese druk (> 5 minute bloedingstyd)

- Installeer valbeskerming vir toegang tot die breker pit

2. Werktuig & Materiaal kontrolelys

| Werktuig | Spesifikasie |

|---|---|

| Hidrouliese domkrag | 50-ton kapasiteit |

| Wringkragsleutel | 300-800 N · m reeks |

| Liner Lifting Clamp | SWL 2,000 kg |

Linervervangingsproses

3. Verwyder verslete voerings

- Los wigboute in diagonale patroon (30% Wringkragvermindering)

- Gebruiklinieverwyderingsgereedskap Om korrosiebinding te verbreek

- Uittreksel Upper Wiggies eers, Dan syplate

4. Skoon & Inspekteer die monteeroppervlak

- Verwyder puin met pneumatiese beitel

- Kyk vir krake met behulp van kleurpenetrant

- Verifieer platheid (< 0,5 mm/m toleransie)

5. Installeer nuwe voerings

| Komponent | Wringkragspesie | Volgorde |

|---|---|---|

| Vaste kakebeen | 650 N · m | Middelpunt |

| Beweegbare kakebeen | 720 N · m | Kruispatroon |

6. Belyningverifikasie

Gebruik laserbelyningsgereedskap om te verseker:

- Parallelisme < 0,2 mm/m

- Vertikale uitloop < 0,3 mm

- Gepasverpletterende kamergeometrie

Prosedures na installasie

7. Inloopproses

- Begin met 50% Voertempo vir 2 ure

- Monitor vibrasie (< 4,5 mm/s RMS)

- Terugkeer na 8 ure werking

8. Dokumentasie & Analise

- Rekordvoering van reeksnommers

- Meet aanvanklike slytasiepatroon

- OpdateringVoorspellende onderhoudskedule

Algemene foute & Oplossings

| Fout | Gevolg | Voorkoming |

|---|---|---|

| Onbehoorlike wringkrag | Voeringbeweging | Gebruik gekalibreerde moersleutel |

| Gemiste belyning | Voortydige dra | Laserverifikasie |

Verbetering van steengroefproduktiwiteit

'N kalksteenbewerking het die vervangingstyd van die voering verminder vanaf 6.5 aan 3.8 ure by:

- Implementering van ons 8-stap-proses

- Gebruik geoptimaliseerde voeringprofiele

- Opleidingsbemanning op breker kinematika

Noodsaaklike instrumente vir doeltreffende vervanging

- Voeringhanteerder met vakuumhyser

- Infrarooi termiese kamera (Kontroleer die temps)

- Digitale dikte meter (Dra meting)

Presisie bespaar koste

Vervanging van kakebeenvoering Vereis begrip van wringkragspesifikasies, Belyningstoleransies, en behoorlike inloopprosedures. Daarom, deur hierdie gids met u voorkomende instandhoudingsprogram enToerustingdokumentasie, Bedrywighede bereik gewoonlik 18-24 Maandvoering lewenssiklusse, selfs in skuurtoestande.

Hoofkwartierkantoor

Whatsapp:+8615225176731

E-pos: [email protected]

Adres: Geen. 1688, Gaoke East Road, Pudong nuwe distrik, Sjanghai, Sjina.

Webwerf: https://www.mill-sbm.com/