E-pos: [email protected]

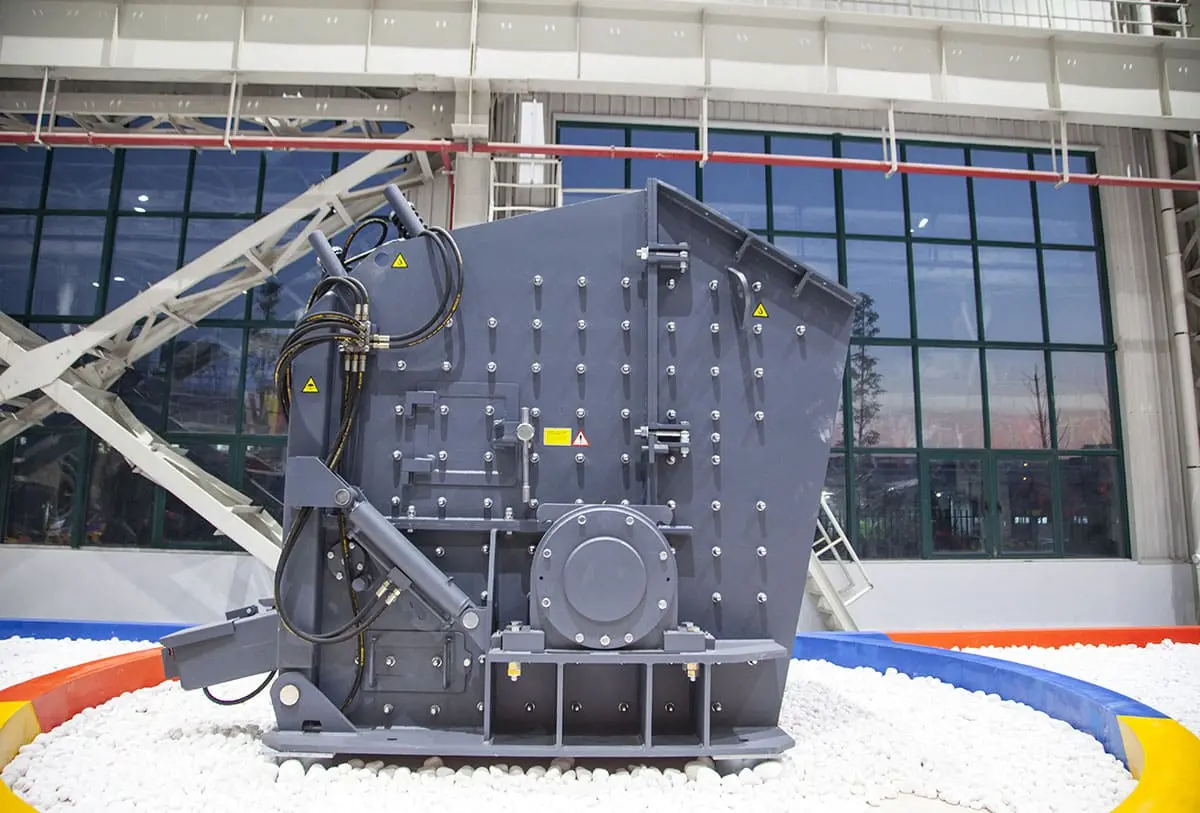

PFW Impact Crusher

PFW Impact Crusher (Also known as “European Impact Crusher”) is mainly used in metallurgy, mine, sement, chemical engineering, fire resistant materials, ceramics and other industries, as well as in the expressway construction, water conservancy projects, aggregate and machine-made sand fields, ens.

Produk Funksies: The use of automated hydraulic jacking device makes checks and maintenance easier and reduces labor costs.

- Invoergrootte: 0-700mm

- Kapasiteit: 70-400TPH

- Materiaal: Kalksteen, veldspaat, kalsiet, talk, bariet, dolomiet, kaolien, gips, grafiet, ens.

Top Technology, Unique Design

PFW Impact Crusher adopts world-class production technologies. It is made up of high-end materials. The design of heavy-duty rotor and strict checks allow the rotor to have high quality. Intussen, the unique fixed device makes the hammer more reliable.

Cast Steel Structure, High Holding Capacity

PFW Impact Crusher’s bearing seat uses integral cast steel structure, which ensures stable operation. Larger bearings boast higher holding capacity.

Semi-automatic Operation Makes Maintenance Easy and Convenient

PFW Impact Crusher can equip the hydraulic control system. By the hydraulic device, the size of discharge opening and the discharging granularity can get controlled quickly. Buitendien, the automatic hydraulic jacking device is helpful for quick replacement of vulnerable parts like the hammer so that the downtime for maintenance can be shortened indirectly.

Simplified Technological Process, Wide Applications

The two-cavity crushing of PFW Impact Crusher can simplify the technological process of coarse and medium-coarse crushing while the three-cavity crushing makes PFW Impact Crusher perform exceptionally well in fine and superfine crushing. Two kinds of crushing cavities can meet the vast majority of coarse, medium and fine crushing operations.

Gedigitaliseerde verwerking, Hoër presisie

Daar is tientalle lyne van numeriese beheermasjiengereedskap. Bewerkings soos staalplate’ sny, buig, skaafwerk, maal en verfbespuiting word alles numeries beheer. Die bewerking akkuraatheid is hoog, veral vir die kerndele.

Voldoende voorsiening van onderdele, Kommervrye werking

SBM, wie se besighede produksie en verkope dek, neem verantwoordelikheid vir elke masjien wat deur onsself vervaardig word. Ons kan kliënte tegniese dienste oor produkte en oorspronklike onderdele bied om die kommervrye werking te verseker.

Werksbeginsel

PFW Impact Crusher breaks materials with impact force. When materials enter the working area of hammer, they may be crushed under the high-speed shock and then thrown onto the impact device above the rotor for another crushing. Volgende, materials bounce from the lining plate to the working area of hammer again. This process repeats continuously until materials reach qualified granularity and are discharged. Adjusting the gap between the impact rack and the rotor rack can change the granularity and shape of finished products. Behind the impact plate is a spring safety device. When unbreakable materials enter the crushing chamber, the impact rack goes backwards to discharge unbreakable materials out of the crusher.

Produk Parameters

| Model | Rotor spec (mm) | Voer opening (mm) | Maksimum voergrootte (mm) | Kapasiteit(t/h) | Krag(kW) | Algehele dimensie (mm) |

| PFW1214Ⅲ | Ф1150×1400 | 570×1430 | 250 | 90-170 | 132 | 2550×2310×2100 |

| PFW1315Ⅲ | Ф1300×1500 | 625×1530 | 300 | 180-270 | 200 | 2960×2570×2380 |

| PFW1415Ⅲ | Ф1400×1500 | 800×1530 | 350 | 280-350 | 250-315 | 3120×2650×2660 |

Let wel:

Produkfoto's en parameters oor modelle, data, prestasies en spesifikasies op hierdie webwerf is slegs vir verwysing. Daar is 'n kans dat SBM veranderinge aan bogenoemde inligting kan maak. Vir spesifieke boodskappe, verwys asseblief na die regte voorwerpe en gebruikershandleidings. Sonder spesiale instruksies, SBM behou die reg om alle data betrokke by hierdie webwerf te verduidelik.