Email: [email protected]

What is The Stone Crusher Machine Price?

The price of a stone crusher machine can vary depending on several factors, including the type of machine, capacity, brand, and additional features or specifications. Market circumstances and geographic location can also affect the pricing. The following are some typical pricing ranges for stone crushing equipment:

- Basic models: The price range for basic stone crusher machines typically starts from around $2,000 to $4,000.

- Mid-range models: The cost of a mid-range stone crusher machine can be anything from $5,000 and $10,000.

- High-end models: High-end stone crushing equipment with cutting-edge features and increased capacity can cost anywhere from $10,000 and $100,000 or more.

What factors affect the price of stone crusher machine?

- Type of Machine: A variety of stone crushing machines, including jaw crushers, impact crushers, cone crushers, and hammer crushers, are offered in the market. Each kind has certain characteristics, requirements, and price points.

- Capacity: The stone crusher machine’s production or capacity is a significant determinant of its pricing. Machines with larger capacities are often more expensive than those with lesser capacities.

- Brand: Because of their reputation for quality, dependability, and durability, well-known brands in the market sometimes have more expensive machines. The price of a stone crushing machine can be influenced by brand awareness and consumer trust.

- Quality and Durability: The price of a machine can be influenced by the machine’s quality and durability, including the materials used in its manufacture. Higher-quality machines often cost more, but they could operate better and last longer because of their superior structure and parts.

- Additional Features and Specifications: Advanced crushing technology, changeable settings, automation, and safety features are examples of additional features and specifications that stone crusher machines may offer that are more expensive than basic ones.

- Market Conditions: Factors including supply and demand dynamics, competitiveness, and market demand may all affect how much stone crushing equipment costs. Prices may be more competitive in marketplaces with many providers that are competitive than they are in settings with few alternatives.

- Geographic Location: Due to elements like shipping expenses, import duties, and regional market circumstances, the geographic location of the machine’s purchase may have an impact on the pricing.

- After-Sales Support: The price of a stone crushing machine can be affected by the availability and caliber of after-sales support, including warranty, technical support, and replacement parts. Prices for machines may be greater if the after-sales service is better.

Prices of SBM various types of stone crusher machines

- Jaw Crushers: SBM provides a variety of jaw crushers with different applications and output capabilities. Depending on the type, capacity, and features, the cost of a jaw crusher can range from a few thousand dollars to tens of thousands of dollars.

- Impact Crushers: SBM produces impact crushers that are appropriate for primary, secondary, and tertiary crushing activities. Depending on the type, capacity, and other features, the cost of an impact crusher from SBM can range from a few thousand dollars to several hundred thousand dollars.

- Cone Crushers: Cone crushers made by SBM are frequently employed in the mining, quarrying, and recycling sectors. Depending on the particular model, capacity, and features, the cost of an SBM cone crusher can range from a few thousand dollars to several hundred thousand dollars.

- Mobile Crushers: SBM provides a selection of mobile stone crushers for on-site crushing applications, including tracked and wheeled models. The model, capacity, extra features, and customization choices for SBM’s mobile crushers can all have a considerable impact on the pricing.

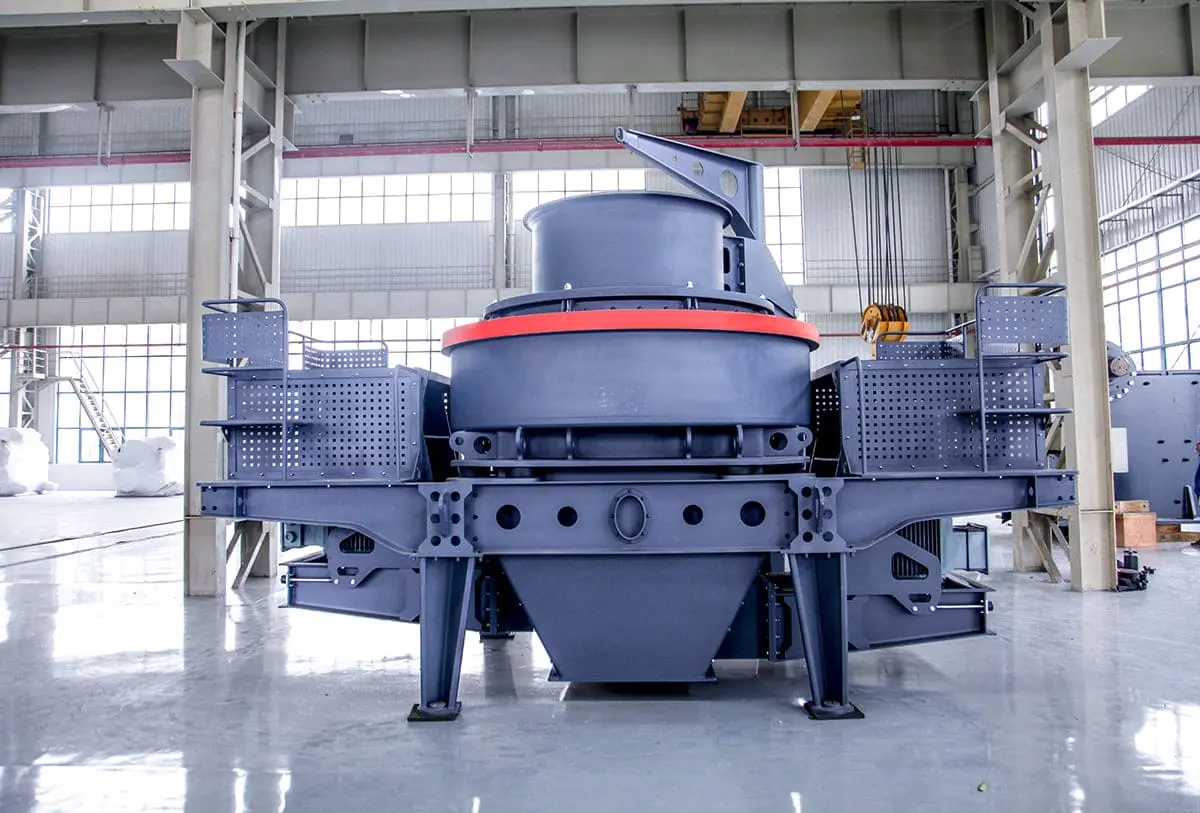

- Vertical shaft impact (VSI) crushers are produced by SBM and are used to shape and finely smash a variety of materials. Prices for SBM’s VSI crushers can range from several thousand dollars depending on the type, capacity, and features.

How does a stone crusher machine work?

High pressure, force, impact, or compression are used by a stone crusher machine to reduce huge boulders to smaller, more manageable sizes.

Feeding: Vibrating feeders are used to feed the stone crusher machine with the rocks or stones that need to be crushed. The material is fed into the crushing chamber in a controlled, regular manner thanks to the feeder.

Crushing Chamber: The crushing chamber, which is lined with robust plates or jaws, is where the rocks are fed. Depending on the kind of crusher, the crushing chamber may have a stationary liner and revolving hammers (impact crusher) or a fixed plate and movable plate (jaw crusher).

Crushing Process: The equipment uses force to break up the rocks or stones into smaller pieces during the crushing process. Depending on the kind of crusher, the specific crushing mechanism varies:

- Jaw Crusher: Rocks are compressed between the moving and fixed plates of a jaw crusher as they travel back and forth against one another. The process reduces the size of the rocks.

- Impact Crusher: The rocks are broken apart by the impact of the revolving hammers or bars. The hammers continually strike the rocks until they are tiny enough to fit through the discharge aperture of the crusher.

- Cone Crusher: Between a fixed cone and a spinning cone, rocks are crushed. As the rocks approach the discharge aperture, they are compressed and crushed by the revolving cone’s eccentric motion.

Discharge: When the necessary size of rock has been achieved, it is unloaded from the crusher machine. By altering the machine’s settings or the location of the plates or jaws, the end product’s size may be changed.

Recirculation (Optional): Some stone crushing equipment has a recirculation system that enables the crushed material to be filtered and returned to the crusher for additional crushing or to reach a particular product size.