Correo electrónico: [email protected]

¿Qué está aplastando en el procesamiento de minerales??

Ever wonder how massive rocks transform into fine powders for metal extraction? Firstly crushing in mineral processing is the foundational step where raw ore gets reduced in size, enabling valuable minerals to separate from waste rock. In short, crushing is the mechanical size reduction of ore using crushers. This occurs after initial blasting at the mine site but before final grinding in mills.

What is the importance of crushing in mineral processing?

The purpose of crushing in mineral processing is liberation—freeing valuable minerals (P.EJ., cobre, hierro) from encapsulating gangue (P.EJ., cuarzo, arcilla)—not mere fragmentation. In other words, crushing breaks these apart, logro “monomer dissociation”—where individual mineral particles separate. Por lo tanto, the higher the dissociation rate, the better the recovery during sorting.

But there’s an economic urgency too:

- Grinding consumes over60% of a plant’s energy budget. Pre-crushing ore finer reduces grinding costs significantly.

- Over-crushing (“over-pulverization“) creates ultra-fines that clog machinery, lower mineral recovery, and waste energy.

From my perspective, balancing liberation with cost is where engineering meets artistry.

What is the purpose of crushing in mineral processing?

The core purpose of crushing in mineral processing is threefold:

- Liberate Valuables

→ Shatter ore tofree trapped minerals (P.EJ., oro, cobre) from waste rock (banda). - Optimize Energy Use

→ Reduce particle sizebefore grinding (grinding consumes>60% of plant energy). - Enable Efficient Downstream Processing

→ Generatecontrolled-size feed for separation (P.EJ., flotation, leaching).

As we emphasized earlier: “Crushing isn’t destruction—it’s targeted liberation.”

Por que importa:

- No liberation = no recovery

- Poor crushing = wasted energy + lost profit

- Over-crushing = ultrafines clog machinery

The Crushing Process: Stages and Key Equipment

Crushing occurs in progressive stages since reducing 1-meter boulders to 100-micron particles demands gradual size reduction. On the whole, the process unfolds as follows:

- Trituración Primaria (Grueso):

- Meta: Reduce run-of-mine ore to ~100–350 mm.

- Equipo: Trituradoras de mandíbulas (for high compression) or gyratory crushers.

- Ejemplo: Bauxite is drilled/blasted, hauled, then primary-crushed before washing.

- Trituración Secundaria (Intermediate):

- Meta: Further reduce to ~20–100 mm.

- Equipo: trituradoras de cono (como el HPT multi-cylinder hydraulic crusher). Its dynamic gap adjustment optimizes particle size while preventing overloads.

- Trituración terciaria (Bien):

- Meta: Achieve 5–20 mm output for grinding feed.

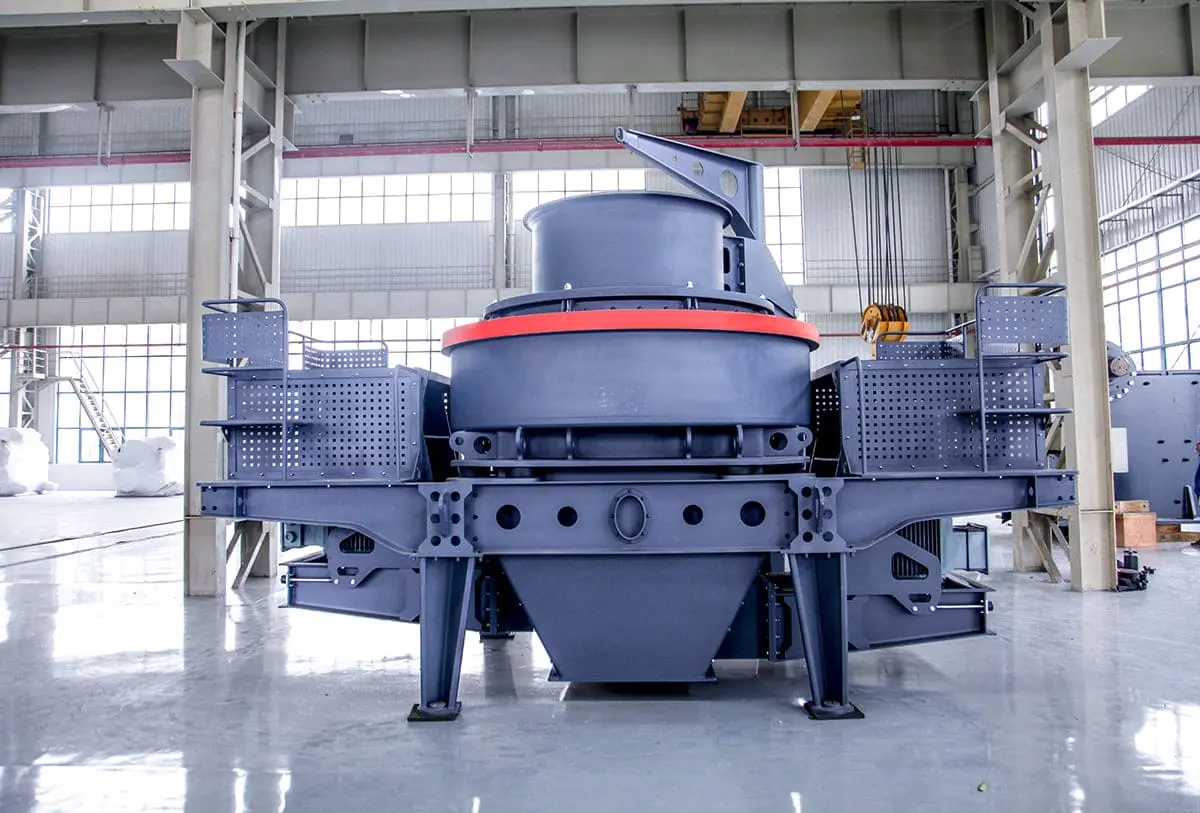

- Equipo: High-pressure grinding roller mills or vertical shaft impact crushers.

How to choose crusher equipment in mineral processing?

Choosing crushing equipments for your mineral processing plant? Here’s the real deal:

1. Know Your Rock’s Attitude

- Duro & Abrasive? (P.EJ., granito):

- Trituración Primaria: trituradoras de quijada oTrituradoras giratorias (they eat hard stuff for breakfast).

- Trituración Secundaria: trituradoras de cono (like the HPT series – handles wear like a champ).

- Sticky & Húmedo? (high clay/moisture):

- Skip easily clogged machines.Trituradoras de Impacto oHigh-Pressure Grinding Roller Mills self-clean better.

2. Define Your Target “Grain Size”

| Escenario | Meta | Equipo | Ejemplo / Notes |

|---|---|---|---|

| Trituración Primaria (Grueso) | Reduce run-of-mine ore to100–350 milímetros | • Trituradoras de mandíbulas (high compression) • Gyratory crushers | Bauxite: Drilled/blasted → Hauled → Primary crushed → Washing. |

| Trituración Secundaria (Intermediate) | Further reduce to20–100 mm | • Cone crushers (P.EJ., HPT multi-cylinder hydraulic crusher) | Dynamic gap adjustment optimizes particle size & prevents overloads. |

| Trituración terciaria (Bien) | Achieve5–20 mm output for grinding feed | • High-pressure grinding roller mills • Vertical shaft impact crushers | Prepares material for downstream grinding processes. |

3. Crunch the Numbers

- Rendimiento: Match the crusher’s appetite (toneladas/hora) to your mine’s diet. Don’t underfeed or choke it.

- Costo de propiedad:

- Power Guzzlers? High-Pressure Grinding Roller Mills cuts energy by 20–35% vs. old-school crushers.

- Maintenance Headaches? Cone crushers often offer lower long-term costs for medium-hard rock.

- Automatización: Smart crushers that self-adjust gaps? Worth every penny for uptime.

Bottom Line:

“Choosing a crusher is like picking a wrench – match the tool to the job. Test your ore’s hardness and abrasiveness first. Size your stages right. Balance upfront cost with long-term savings. Haz esto bien, and your whole plant runs smoother.”

→Pro Move: Always lab-test your ore (Bond Work Index, abrasion tests). Simulate your flow. Data beats guesswork every time.

What is the key applications of mineral crusher?

Mineral crusher is the unsung hero across mining and aggregates. Picture it:

- Metal Ore Processing: Massive blocks of copper, hierro, or gold ore are initially reduced to manageable sizes using jaw crushers or gyratory crushers.

- Producción Agregada: Granito, caliza, and sandstone are precisely shaped into graded concrete or road base by cone crushers and impactors.

- Reciclaje & Secondary Recovery: Concreto, asfalto, and demolition waste are processed by mobile tracked crushers, effectively turning discarded material into a revenue stream.

- Industrial minerals: Specially designed sizers process sticky, high-moisture materials like clay or shale—where traditional crushers clog and fail

💡 I once saw a quarry lose 3 days’ production trying to force wet limestone through a standard jaw crusher. The right machine matters.

Automation Revolution: Smarter Mineral Crushing Systems

Modern plants rely on IIoT and AI for:

- Predictive adjustments: PLCs monitor load, presión, and wear, altering speed/feed to prevent jams.

- Remote operations: Control centers manage crushing lines from miles away.

- Seguridad: Reducing human exposure to dust, ruido, and moving parts.

As ore grades decline, smarter crushing isn’t optional—it’s survival.

Oficina central

Whatsapp:+8615225176731

Correo electrónico: [email protected]

DIRECCIÓN: No. 1688, Camino del este de Gaoke, Nuevo distrito de Pudong, Llevar a la fuerza, Porcelana.

Sitio web: https://www.mill-sbm.com/