Correo electrónico: [email protected]

Guía de placa de mandíbula: Tipos, Materiales, Precios & Consejos de selección

Why Jaw Plates Matter?

Let’s face it—if you’re running a crushing operation, your jaw plate choice is as crucial as any big investment. The right jaw plate isn’t just a metal slab—it’s the real MVP in converting raw rocks or ores into usable material. This guide will walk you through everything you need to know about jaw plates, ensuring your decision is smart, cost-effective, and performance-driven.

What Is a Jaw Plate?

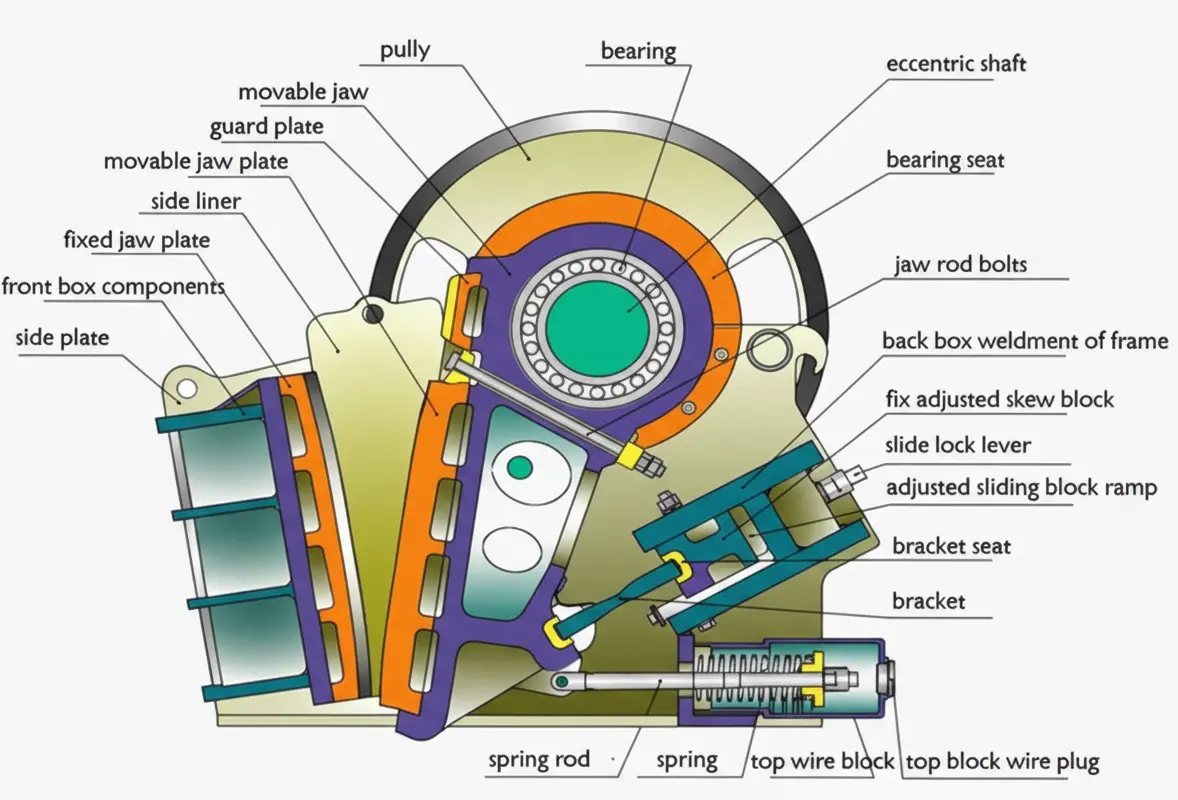

A jaw plate is the key wear part of a rompe mandíbulas, directly facing and breaking down the materials fed into the chamber. Típicamente, jaw crusher designs have two plates: a stationary one and a movable one. The movable jaw plate exerts pressure, crushing the feed material against the fixed jaw plate. Think of it as a powerful set of mechanical jaws chomping rocks until they’re small enough to slide out.

Jaw Plate Location & Their Role in Crushers

Jaw plates are mounted inside the jaw crusher’s “cheeks,” directly lining the crushing chamber. These plates:

- Form the chamber walls

- Absorb direct impact and abrasion

- Transfer crushing force from the motor to the material

- Guide broken pieces downward for output

If you picture your crusher’s insides, jaw plates are front and center, working non-stop to process every load that drops in.

Popular Jaw Plate Types

Each application and feed type calls for a specific jaw plate profile. Here are the most common types you’ll encounter:

| Jaw Plate Type | Profile / Características | Mejor para | Typical Material |

|---|---|---|---|

| Standard/Straight Plate | Departamento, even surface | General purpose | Manganese Steel |

| Corrugated Plate | Wavy for grip | Abrasive/irregular materials | Manganese Steel |

| Toothed Plate | Teeth or ridges for bite | Rocks, chatarra, concreto | Chrome Iron, Alloy |

| Slab Breaker | Top/bottom striking faces | Grande, slabby material | High Manganese Steel |

| Cheek & Grid Plates | Sides/supports, allow sizing | Crusher protection/size sorting | Manganese Steel |

| Wedge/Quarry Tooth | Special angle or mass | Bruto, non-uniform rocks | Manganese Steel, TIC |

Different jobs demand different tooth profiles and alloys. Por ejemplo, corrugated can grip and process tough ore, while toothed plates are excellent for demolition or recycling.

Materials Used For Jaw Plates

Choosing the right jaw plate material impacts crusher efficiency, lifespan, y mantenimiento. Here are the big contenders:

- Manganese Steel (Mn14Cr2, Mn18Cr2, Mn22Cr2): Offers work-hardening, meaning it gets tougher the more it’s used. Great for high-impact jobs like hard rock and ore.

- High Chrome Iron: Extremely hard and impact-resistant, best where sharp bite and longer life are priorities.

- Titanium Carbide (TIC) Composite: For the toughest abrasive applications; marries durability with exceptional wear resistance.

- Microalloy & Alloy Steel: Improved hardness and lifespan, sometimes used in specific small crushers or tough conditions.

Actuación & Lifespan Table

| Material | Relative Hardness | Impact Resistance | Mejor uso | Rough Market Price (per piece) |

|---|---|---|---|---|

| Manganese Steel | Medium-High | Very High | General mining/rock | $400–$550 |

| High Chrome Iron | Alto | Medio | Abrasive/hard materials | $450–$600 |

| Titanium Carbide Insert | Very High | Alto | Top abrasion, larga vida | $650+ |

| Alloy/Microalloy Steel | Medio | Medio | Small jobs, specific ores | $300–$500 |

Prices depend on size, source, and tonnage. Always check for volume discounts or custom solutions.

Market Prices & What Drives Them

Market prices for jaw plates in 2025 generally range from $400 to over $650 per piece, depending on:

- Material: High manganese and composite alloys cost more, but deliver a longer life.

- Design complexity: Custom profiles or inserts (like TIC) may boost costs.

- Supply fluctuations: Prices can go up with global steel trends or supply chain hiccups.

For large operations, buying in bulk or signing long-term contracts may help with stable pricing.

Relationship Between Jaw Plate & Crushing Material

Selecting the wrong jaw plate for your feed material is like using a butter knife on granite—possible, but costly and slow! Here’s how to match plates with materials:

| Material de alimentación | Ideal Plate Profile | Recommended Material |

|---|---|---|

| Granito, Basalto | Corrugated, Toothed | Mn18Cr2, Mn22Cr2, TIC Insert |

| Caliza, Shale | Standard, Departamento | Mn14Cr2, Alloy |

| Recycled Concrete | Toothed, Slab Breaker | High Chrome, TIC |

| River Gravel | Wedge, Super Grip | Manganese Steel |

Duro, abrasive feeds demand harder, longer-wearing plates. Manganese with TIC insert can greatly slow down wear when the going gets tough.

How to Choose the Right Jaw Plate: Consejos prácticos

Let’s keep this practical. Here’s exactly how to avoid wasting time—or money.

- Know Your Feed: Is it hard, abrasive stone or softer material?

- Check Crusher Model & Mount: Some jaw crushers need bolt-on, others wedge-style plates.

- Don’t Over/Under-Spec: Recordar, harder is not always better for every job. Overly hard plates on soft stone may not justify the price.

- Balance Cost vs. Longevidad: Higher-grade materials cost more, but can last multiple times longer—crunch the numbers!

- Consult With Experts: Discuss your operational needs with suppliers, especially for specialized environments.

Jaw Plate Maintenance and Replacement

To get the best value from your jaw plates:

- Inspect regularly: Check for cracks, chips, or excessive wear.

- Clean and lubricate: Prevent debris buildup and reduce friction.

- Rotate plates: If possible, rotate plates to balance the wear.

- Replace on time: Don’t wait until the plate is paper-thin—productivity drops fast and could damage your crusher.

- Follow manufacturer installation procedures: Incorrect fitting may lead to premature failure or even safety hazards.

Common Signs Your Jaw Plate Needs Replacing

You should consider replacement if:

- The plate is worn down to beneath manufacturer’s recommended minimum thickness (often 25–50mm).

- You notice uneven wear, grietas, or material slipping through.

- Production rate drops sharply.

- Your crusher starts to vibrate more, or you can hear more “clatter” than usual.

Timely replacement saves your crusher from costlier breakdowns down the line.

Mesa: Typical Jaw Plate Maintenance Schedule

| Activity | Frecuencia | Notes |

|---|---|---|

| Visual Inspection | Weekly or each shift | Look for cracks, chips, tener puesto |

| Cleaning | Once per Week | Removes debris |

| Lubricación | Per manufacturer spec | Reduces friction, tener puesto |

| Plate Rotation | When wear is uneven | Extends total lifespan |

| Replacement | Thickness < 25–50mm or as needed | Prevents crusher damage |

Nota personal & Hands-On Insight

Honestamente, for anyone in the crushing business, a good set of jaw plates is like sturdy work boots—essential and worth every penny. Your bottom line depends on minimizing downtime and maximizing throughput. Investing in the best fit (not just the priciest or the hardest) plate is the key to smoother, more efficient operations.

Como fabricantes, we see it all: from operators who stretch their plates past the “safe zone,” to those who swap out early and keep things humming. With the right selection and regular checks, you’ll stay ahead of the costly surprises.

Quick Jaw Plate Selection Chart

| Your Situation | Best Jaw Plate Material | Best Profile |

|---|---|---|

| Hard/Abrasive Ore | Mn22Cr2, TIC Insert | Corrugated or Toothed |

| Materiales reciclados | High Chrome, Alloy | Slab Breaker, Toothed |

| Budget Operation | Mn14Cr2, Alloy | Straight/Flat |

| Max Longevity Needed | TIC, Composite | Any, customized |

Closing Thoughts

With the right jaw plate, your crusher’s productivity soars, downtime drops, and costs are easier to control. Use the details, charts, and tips above as your cheatsheet for choosing the perfect jaw plate in 2025—and keep crushing it, día tras día!

If you need expert advice or have unique application challenges, reach out for practical, data-driven solutions. The right plate isn’t just a part—it’s a difference-maker in your entire operation.