Correo electrónico: [email protected]

Guijarros de río

Contenido principal

Mirar, in our world of crushers, pantallas, and hard-wearing liners, few things get equipment guys like me fired up quite likeguijarros de río (oriver rock, if that’s your local term). These water-tumbled stones? They’re nature’s perfect aggregate – tough as nails and gorgeous to boot. But crush ’em wrong? You’ll burn through wear parts faster than cash at a trade show bar. Let’s cut through the noise and talk real-worldriver pebble tratamiento.

Why River Pebbles Are a Love-Hate Relationship?

Born in the Rapids: What Makes ‘Em Tick

- How They Form: These buggers start life as jagged mountain rock – granito, basalto, you name it. Centuries of river abuse smack ‘em around, smooth their edges, polish their faces, and sort ‘em like a OCD sieve.

- Why We Crave ‘Em:

- Harder Than Your Ex’s Heart: Surviving river torture means they laugh at abrasion. Perfect for heavy-duty concrete or driveways.

- Water? No Thanks: Tight structure means low absorption. No spalling in freeze-thaw hellscapes.

- Pretty Darn Handsome: Smooth, rounded, colors from moon-white to volcanic black. Landscapers swoon.

- La captura: That smooth shape sucks for concrete binding. Needs crushing or smart mix designs.

- Green Points (Maybe): Sometimes less energy than quarrying rock… si you source responsibly.

Digging ‘Em Up: Don’t Be That Guy

- Do It Clean: Permits. Habitat checks. Reclamation plans. Skip this, and you’re the jerk killing trout streams for gravel.

- Ubicación, Ubicación, Ubicación: Hauling dense river rock 200 miles? Kiss profits goodbye. Mine close or don’t bother.

- Sort at Source: Screen out dirt, arena, and twigs antes trucking. Paying to move mud? C’mon.

Mesa 1: River Pebble Sizes – Where They Shine

| Tamaño (milímetro) | What We Call ‘Em | Where They’re Gold |

|---|---|---|

| 2-8 | Pea Gravel | Paths, playgrounds, fancy garden mulch |

| 8-16 | Small Fry | Landscaping beds, aquarium bling (washed!) |

| 16-32 | Workhorse Pebbles | Dry creek beds, desagües franceses |

| 32-64 | Showstoppers | Water features, erosion armor |

| 64-128 | Cobbles | Bank armor, serious landscaping biceps |

| 128+ | Boulders | Riprap monsters, statement pieces |

Why River Pebbles Break Machinery?

| Propiedad | Verificación de la realidad | Profit Killer |

|---|---|---|

| Dureza | 6-7 Mohs | Wear part costs jump 40% VS. granito |

| Humedad | Arriba a 15% in monsoon season | Clogged screens = 20% downtime |

| Forma | Round = poor compaction | Concrete clients reject “ball bearing” agregar |

| Abatría | High quartz content | Cintas transportadoras shred in 4 meses |

Translation: Your maintenance budget needs steroids.

Crushing River Pebbles: Where Men Cry and Machines Die

Está bien, let’s get dirty. Yeah, guijarros de río are tough. But their smooth, round faces? They’ll slide through your crusher like buttered marbles if you pick the wrong kit. And that hardness? It eats liners for breakfast. Get this wrong, and your profit margin vanishes faster than donuts in the breakroom.

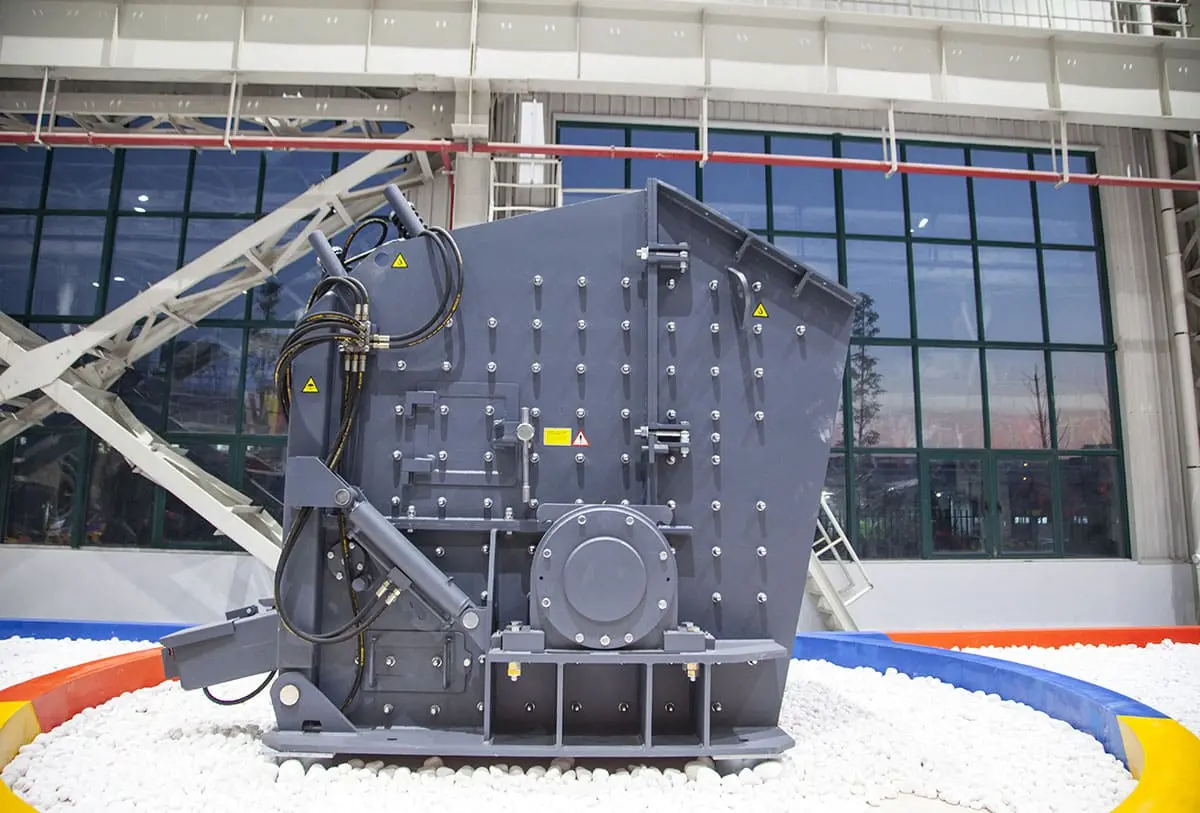

Crusher Showdown: Picking Your Gladiator

- The Problem: Smooth + hard = sliding + tener puesto. Your machine needs a deep bite (sharp nip angle) and armor-plated guts.

- Contenders:

- trituradoras de cono (My Go-To): For consistent sizing and decent shape. Modern hydraulics? Game-changers.

- Why I Dig ‘Em: Built like tanks. Adjust on-the-fly. Wear cost per ton? Respectable.

- Desventaja: Shape isn’t perfectly angular. Fine for most concrete, but not super-premium.

- Real Talk: Run ‘em closed-circuit with a screen. Recycle oversize. Saves money and tears.

- VSI Crushers (The Shape Masters): Need cubical aggregate for high-strength concrete? This is your jam.

- Why They Rock: Throw pebbles against anvils = beautiful, binding-friendly angles.

- La captura: Wear costs can sting. Feed ’em pre-crushed pebbles (4-6″ ideally), not boulders. Y sí, they make fines.

- My Take: Use AFTER a cone crusher. Trying to VSI raw river cobbles? Prepare for pain.

- trituradoras de quijada (The Bouncer): Only for the big boys. Got boulders? Let the jaw smash ‘em down first. Feeding direct river run? Nope. They’ll just rattle around.

- HPGR? (The Wildcard): Seen ‘em work on hard rock. Para guijarros de río? Jury’s out. Maybe for sand making? Needs a hard look.

- trituradoras de cono (My Go-To): For consistent sizing and decent shape. Modern hydraulics? Game-changers.

Support Crew: Don’t Skip These

Crushing’s just round one. Miss these steps, and you’re selling junk:

- Poner en pantalla: Multi-deck vibrators. Split your crushed river rock into money-making fractions (5-10milímetro, arena, etc.). Bad screening = lost specs = lost customers.

- Lavado & Scrubbing: River muck sticks. For concrete? You need clean aggregate. Attrition scrubbers blast off clingy clay. Worth every penny.

- Sand Savers: Screw classifiers or cyclones. Reclaim that sand from wash water. Profit hiding in your sludge.

Gear Philosophy: Buy Tough or Cry Twice

Let’s be blunt: River pebbles chew up equipment. Your choices?

- Wear Parts: Go big or go home.

- Cones: High-chrome mantles/concaves.

- TODOS: Tungsten tips, carbide anvils.

- Screens: Polyurethane or woven wire for longer life.

- Build Quality: Flimsy frames? Walk away. Overbuilt bearings? Yes please.

- Maintenance Access: Can your guy swap a liner in under 4 horas? If not, redesign. Downtime = bankruptcy.

Personal Rant: I’ve seen plants where the crusher access panel needs a contortionist. Drives me nuts. Design for the grease-monkey, folks.

Making Money With River Rock: 5 Proven Paths

1. High-Stakes Concrete Aggregates

Crushedguijarros de río make phenomenal concrete –si you achieve angular fractures. Rounded particles? Kiss your spec goodbye. Para la punta: Ampliadores de impacto > jaw crushers here.

2. Landscaping’s Dirty Secret

Big-box stores markup decorativeriver stones 300%. But clients want color-sorted, dust-free pebbles. Our rotary scrubber pays for itself in 8 meses.

3. The Aquarium Goldmine

Surprise profit center: Pet stores pay premium for 5-20mmnatural cobbles. Just ensure 0% caliza (acid test everything).

4. Industrial Grinding Media

Cement plants buy truckloads of 40-70mmfluvial stone. Hardness = slower wear in ball mills.

5. Erosion Control’s MVP

Engineers specify 50-150mmpebble aggregate for seawalls. No crushing needed! Margins hit 35%.

Wrapping It Up: Piedra, Acero, and Smarts

River pebbles aren’t just rocks. They’re a test. Can your kit handle nature’s toughest smooth operators? Get the crusher right (cone for efficiency, VSI for shape), pair it with smart washing and screening, and spec wear parts that don’t fold. Do that, and you turn riverbed leftovers into premium aggregate.

Seeing a well-set plant crunchingriver rock all day, with liners lasting weeks not days? That’s the good stuff. That’s where engineering meets the grind – and wins. Next time you walk a job site seeing that gravel path or polished concrete, tip your hat to theriver pebble… and the tough-as-hell gear that tamed it.