Correo electrónico: [email protected]

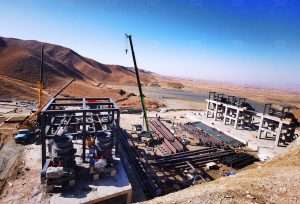

Planta de trituración de granito

El cliente es la compañía de desarrollo inmobiliaria local más grande, que necesita una gran cantidad de agregados de arena cada año. A medida que el precio de los agregados aumenta rápidamente, El costo de las materias primas para los clientes aumenta bruscamente. In order to meet their needs for aggregates, they decided to use their own granite resource to build a sand making plant. In June 2018, the client selected SBM as partner and established a granite crushing production line of 250-300 montones. The project was completed and put into operation in March 2019. Currently, the granite crushing plant is running normally, not only meeting the customer’s needs, but becoming a local landmark project.

Perfil del proyecto

- Materia prima: Granito

- Capacidad: 250-300HTP

- Tamaño de salida:0-5-10-20-31.5milímetro

- Aplicaciones:Used to make aggregates and dry-mixed mortar

- Equipo principal:F5X1360 Feeder, PEW860 Jaw crusher, HST315 Cone crusher, VSI6X1150 Sand maker, S5X2760-2 Vibrating screening

Ventajas

- The whole granite crushing plant is highly automated with efficient operation, low maintenance intensity and cost. The high quality of finished products is very good.

- The project adopts series high quality equipment like PEW jaw crusher, HPT cone crusher and VSI6X sand making machine, which make the production more efficient.

- PEW adopts the wedge adjusting device, which makes operation simple and safer. Además, HPT cone crusher adopts PLC liquid crystal display control system and hydraulic adjusting discharge, which is highly intelligent and automatic.

- VSI6X sand maker adopts new feeding design and “Rock on Iron” Crushing mode, which has two functions of shaping and making sand, its finished product has better grain shape.