Correo electrónico: [email protected]

Piedra de granito triturada

Hogar » Piedra triturada » Piedra de granito triturada

Contenido principal

Crushed Granite Stone is a durable, eco-friendly aggregate for driveways, landscaping, y construcción. Offers superior drainage, 100–250 MPa compressive strength, and versatile sizing for cost-effective, superficies estables.

If you’re looking for a durable, versatile, and eco-friendly material for your next project, crushed granite stone might just be the way to go. I’ve heard it from my clients time and again. Trust me—it makes a real difference! This guide will go into detail on everything you need to know: from applications and benefits to sizing tips. Let’s get started.

What Exactly Is Crushed Granite Stone?

Crushed granite is a natural aggregate made by mechanically breaking solid granite into angular pieces. Unlike rounded river gravel, its jagged edges snap together to create a stable surface. Crushed granite ranges in size from a fine powder (“weathered granite”) to coarse chunks. Interesting fact: The mineral components of granito (such as quartz and feldspar) give it its signature mottled appearance and exceptional durability.

Arriba 5 Uses for Granite Aggregate

- calzadas & Caminos: Its compactibility makes it ideal for base layers.

- paisajismo: Perfect for garden paths, patios, or decorative ground cover.

- Construcción: Used in concrete mixes and drainage systems.

- Control de erosión: Stabilizes slopes and shorelines.

- Railroad Ballast: Supports tracks due to its weight and drainage properties.

I once replaced my muddy backyard trail withgranite aggregate—zero weeds and all-weather usability!

Why Choose Crushed Granite? Key Benefits

- Durabilidad: Resists weathering and heavy loads (compressive strength: 100–250 MPa).

- Eco-Friendly: 100% natural and recyclable.

- Drenaje: Gaps between particles prevent water pooling.

- Aesthetic Appeal: Rustic charm with color variations (gris, rosa, or gold).

- Económico: Cheaper than pavers or solid slabs.

Popular Sizes of Granite Gravel and Their Uses

Here’s a quick reference table to matchgranite stone aggregate sizes to your project:

| Tamaño (milímetro) | Common Name | Mejor para |

|---|---|---|

| 0–5 | Decomposed Granite | Paths, playgrounds, soil amendment |

| 5–10 | Fine Granite Chips | calzadas, decorative mulch |

| 10–20 | Medium Granite Gravel | Base de la carretera, drainage layers |

| 20–40 | Coarse Granite Rock | Landscaping accents, erosion control |

Tip: For driveways, pair a 20–40mm base with a 5–10mm top layer for smoothness!

How to Source Quality Crushed Granite Stone?

Not allcrushed granite is created equal! When buying:

- Check Gradation: Ensure uniform particle sizes (ask for sieve analysis reports).

- Verify Hardness: Opt for granite with >6 Dureza de mohs (like SBM China’s quarries).

- Consider Color: Match your project’s aesthetic—e.g., gray for modern gardens, pink for warm tones.

Aparte de esto, we can also use manual crushing or jaw crushers (for coarse aggregates) y trituradoras de martillos (for fine aggregates) to crush granite or other ores.

Why Crushers Deliver Superior Crushed Granite Stone?

Unlike hand-crushing, mechanical crushers ensure:

✅Consistent particle size (critical for compaction and drainage).

✅Angular fragments (interlocking stability).

✅Minimal dust/debris (via built-in screens or air filters).

✅Scalable output (from decomposed granite powder to 40mm road base).

3 Crusher Types for Every Project Scale

| Tipo | Escala de proyectos | Aporte | Producción | Mejor para | Tip/Hack | Costo |

|---|---|---|---|---|---|---|

| Portable Jaw Crushers | Small-Medium Projects | Raw granite boulders (≤500mm) | Coarse aggregate (10–40mm) | On-site recycling of demolition waste or quarry leftovers | Add vibrating screen to separate fines (0–5 mm) for pathways | Rent for ~$200/day (ideal for driveways/landscaping) |

| trituradoras de cono | Medium-Large Production | Pre-crushed chunks (≤150mm) | Uniform medium gravel (5–20mm) | High-volume projects requiring precise gradation (P.EJ., railroad ballast) | Pair with dust suppression system to reduce silica exposure | – |

| Trituradoras de Impacto | Bien agregado & Specialty Shapes | Medium granite pieces (≤100mm) | Cubic-shaped chips (3–10mm) or decomposed granite (0–5 mm) | Decorative gravel or concrete mixes needing smooth edges | – | – |

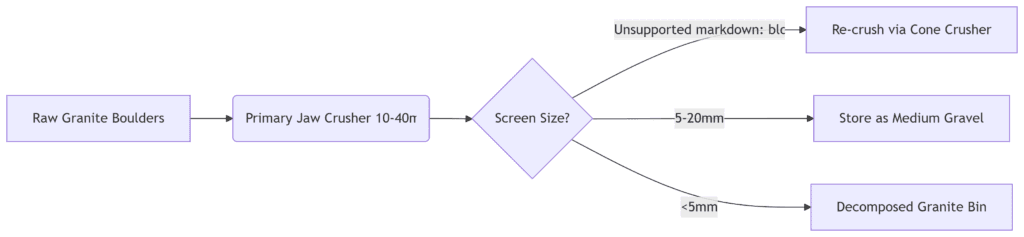

Crusher Workflow: From Raw Rock to Premium Aggregate

Follow this sequence for optimal quality:

Nota: Always test output with a sieve kit—adjust crusher settings if >15% particles deviate from target size.