Correo electrónico: [email protected]

Gabro

Contenido principal

Está bien, let’s talk shop. If you’re in the business of processing hard rock, you’ve likely crossed paths withGabro. It’s the backbone of countless construction projects, but let’s be honest—it’s an absolute beast to work with. Its very strength, the reason it’s so valuable, is what chews up equipment and spits out downtime and blown budgets.

I’ve been in the mineral processing game for decades, and at SBM China, we see these challenges every single day. This guide isn’t full of fluffy theory. It’s a straight-talking, practical manual from one professional to another. We’re going to break down whatGabro es, why it’s such a headache, y lo más importante, how to configure a crushing and grinding circuit that doesn’t just handle it, but dominates it, turning a profit-killer into your most reliable earner.

Entonces, grab a coffee, and let’s get into it.

What is Gabbro?

Lo primero es lo primero, you’ve got to know what you’re dealing with. Think of gabbro as basalt’s tougher, older brother that cooled down deep underground, taking its sweet time. That slow cooling is the key—it allowed big, interlocking crystals to form, creating a rock that’s incredibly dense and mechanically strong.

Mineral-wise, it’s loaded with calcium-rich plagioclase feldspar, pyroxene, and often a bit of olivine. This mix is what gives it that famous hardness and abrasiveness. For us on the processing side, this translates to one thing: a serious, relentless wear on everything that touches it. You don’t just throw any machine at this stuff; you need equipment built for a fight.

Where Gabbro Hangs Out and What That Means For You?

Gabro isn’t everywhere. You’ll find it in the thick layers of oceanic crust and in those massive underground magma chambers called layered intrusions. From the quarries of Norway and Italy to major operations in India, Brasil, and North America, it’s a global player.

But here’s the critical part: not all gabbro deposits are created equal. Is it a massive, uniform block? Or is it layered, with zones of varying hardness and fracture? This isn’t just academic; it’s the difference between a smooth-running operation and a constant battle. Spending the time and money on a proper geological survey before you even order equipment isn’t a cost—it’s the smartest investment you’ll make. It tells you exactly what you’re feeding your primary crusher.

Gabbro’s Properties That Wreck Equipment

Let’s look at the cold, hard numbers. This is what keeps plant managers up at night.

- Hard as Nails: We’re talking a Mohs hardness of 6-7. This means extreme, rapid wear on crusher liners, mantos, placas de mandíbula, and grinding media. Abrasion is your constant, expensive enemy.

- Immense Strength: Its compressive strength is huge, often between 200-300 MPA. This demands crushers that can generate and withstand enormous force.

- Dense and Heavy: This means more mass going through your system, requiring robust conveyors, feeders, and structures.

- Low Silica: A small mercy for health and safety, but it does nothing to reduce the mechanical challenge of breaking it.

| Propiedad | Typical Value Range | What It Means on the Ground |

|---|---|---|

| Density | 2.9 – 3.1 g/cm³ | Pesado. Needs heavy-duty equipment. |

| Compressive Strength | 200 – 300 MPA | Requires high-force crushers (Jaw/Cone) |

| Mohs Hardness | 6 – 7 | Severe abrasiveness. Major wear part costs. |

| Water Absorption | Muy bajo (<0.1%) | Less issue in washing stages, a small win. |

Why do we process gabbro?

So why put up with this headache? Because the payoff is big. When you process gabbro correctly, you’re creating premium, high-demand products.

Its primary use is as top-tier crushed stone aggregate for concrete, asfalto, and road base. Its strength and durability make it the go-to for heavy-duty infrastructure projects that need to last. Furthermore, when it’s polished up, it’s sold as “black granite,” a high-value dimensional stone for countertops, flooring, and building cladding.

Beyond construction, certain types of gabbro can be a source of nickel, chromium, and platinum group metals, though that requires more complex mineral processing. The bottom line: this rock is worth the effort.

How should we process gabbro?

Taming gabbro is a step-by-step battle of attrition. You can’t skip stages. A well-designed flow sheet is your master plan.

- Perforación & Blasting: The initial size reduction at the quarry face.

- Trituración Primaria: The first mechanical stage, taking meter-sized boulders down.

- Trituración Secundaria: Further reduction to a manageable size for final crushing or screening.

- Terciario/Fine Crushing: Getting the product to the final aggregate size.

- Poner en pantalla: The crucial sorting process that defines your final products and optimizes efficiency.

- Molienda (if needed): For producing sand (mechanized sand) or fine powders.

- Lavado & Dimensionamiento final: Producing clean, spec-ready aggregate.

Escenario 1: Trituración Primaria

This is where you meet the run-of-mine gabbro cantos rodados, face-to-face. This stage is about raw power and reliability. You need a crusher that’s all about brute force.

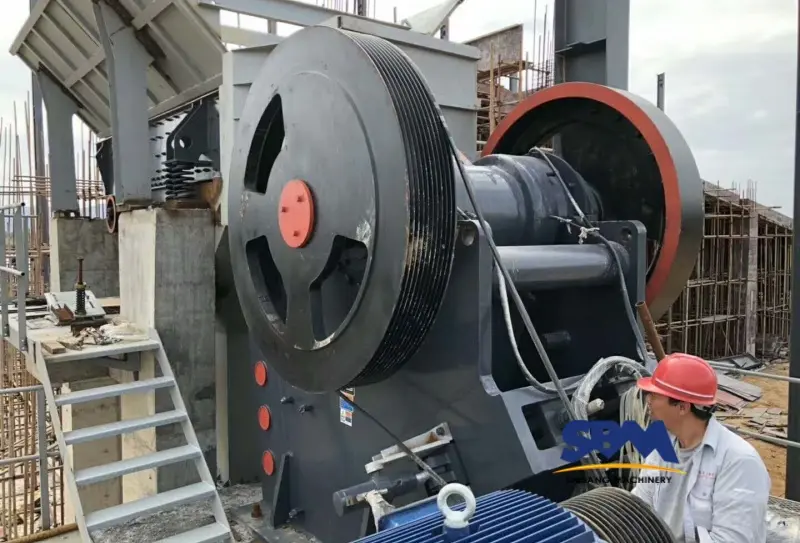

Para gabbro, the only real choice for primary crushing is a Rompe mandíbulas. Its design is perfect: a massive fixed jaw and a moving jaw create a powerful compressing motion that breaks the toughest rock by sheer force. It’s the workhorse.

When selecting a primaryrompe mandíbulas for this job, you cannot compromise on:

- Build Quality: The frame and pitman must be incredibly robust to handle the shock loads. Look for heavy-duty cast steel construction.

- Fuerza: The motor needs high torque to power through the toughest sections without stalling.

- Wear Parts: The jaw plates must be premium manganese steel, designed for maximum wear resistance. This is your first line of defense, and it must be strong.

A proper primary crusher sets the tone for the entire plant, creating a consistent feed that maximizes the efficiency of everything downstream.

How to Choose the Right Jaw Crusher? It’s All in the Details

Not all jaws are built the same. You need a model designed for a hard, abrasive life. Here’s what to scrutinize:

- Abertura de alimentación: Big enough to swallow your largest boulders without a fuss.

- Capacidad (HTP): Must match or be higher than your plant’s production goal. Avoid choosing one that’s too small!

- Power Rating: Enough power is absolutely essential. A weak crusher will cause ongoing issues.

- Configuración lateral cerrada (CSS) Range: Gives you flexibility in your output product size.

- Durability Features: Look for elements like a strong toggle plate that serves as a safety device to shield the crusher from unbreakable objects.

A crusher such as our C6X Series Jaw Crusher is designed for this task. Its modular design and non-welded frame are built to endure daily abuse from Gabbro. Its improved movement means not only higher output but also more evenly shaped product, which helps the next crushing stage work better.

Escenario 2: Secundario & Tertiary Crushing – Shaping Your Profit

After the jaw crusher, you’ve got rock around 150-250mm. For most aggregate specs, that’s still too big. Now the goal shifts from brute force to controlled reduction and shaping. This is where you earn your money by creating a high-value, cubicle product.

Aquí, el Trituradora de cono is the top choice. Its working method is perfect for hard, roca abrasiva. A spinning mantle presses rock against a bowl-shaped liner. The material is crushed both by squeezing and by rocks grinding against each other as they move downward.

What makes modern hydraulic cone crusher so useful in Gabbro processing is their self-protection ability. They detect overloads and can change settings or clear the chamber in moments, avoiding expensive damage and stopping production. This automatic function is crucial for keeping operations running smoothly.

Why Cone Crushers are a Gabbro Plant’s Best Friend?

The design of cone crusher is highly effective for hard stone. Mixing compression and rock-on-rock crushing works very efficiently to break gabbro while also creating valuable, well-formed aggregate that sells for more.

When choosing a cone crusher, you’ll pick a cavity type based on your need:

- Coarse/Standard Cavity: Used for secondary crushing; output is usually 40-100mm.

- Fine/Short Head Cavity: For tertiary crushing, getting down to those final aggregate sizes like 5-20mm.

A crusher like our Trituradora de cono hidráulica de varios cilindros HPT brings this all together. With features like hydraulic adjustment, automatic cavity clearing, and a large crushing force, it gives you the control and throughput needed to precisely shape tough gabbro into a premium product, all while protecting itself.

Screening in a Gabbro Circuit

Crushing and screening go hand in hand. If you try to use one without the other, you won’t run efficiently. Think of the screen as the quality and efficiency manager of your operation.

- Makes the Product: It sorts the crushed material into exact sizes that your customers need and are willing to buy.

- Boosts Efficiency: In a closed-loop system, it returns oversized pieces to the crusher for another round. This makes sure the crusher only processes what needs more breaking, greatly boosting total output and reducing wear.

- Protects Equipment: It makes sure that only correctly sized material moves on to the next machine.

Screening abrasive gabbro demands tough screens. You need vibrating screens with hardened decks or long-lasting polyurethane screen panels. A smart screening setup is what transforms a simple crushing line into a high-yield, profit-optimizing factory.

When You Need to Go Fine: The Grinding Stage?

Crushed aggregate is useful, but sometimes you need something finer. If you’re making gabbro sand for concrete (also called M-Sand) or fine powder for other uses, you’ll need to grind. Be aware: this stage uses much more energy, so selecting the right mill is vital for keeping costs low.

The aim here is to take particles from the crushing stage (around 0-5mm) and turn them into sand or powder. This involves hitting, rubbing, and squeezing the material. Para gabbro, this is the toughest test any mill can face.

Ball Mill vs. Molino vertical: The Technology Choice

This is the big decision. Each technology has its place, and the right choice depends on your product and cost structure.

- Fábrica de bolas: The traditional option. It uses a spinning drum with steel balls that crush the material through impact and grinding. It’s a trusted and reliable method that can make very fine powder. But with Gabbro, the wear on the lining and balls is very high, leading to more cost for replacements and maintenance. It also uses a lot of power—it’s not very efficient.

- Molino vertical (VRM): The newer, efficient option. Material is placed on a spinning table and crushed by rollers under high pressure. The biggest advantage with gabbro is its much better energy efficiency—often using 15–20% less power than a ball mill. The parts that wear out (like roller tires and table liners) also last longer and are easier to change. It has a built-in classifier that lets you accurately control how fine the product is, which is a major benefit.

For making gabbro sand or powder, a mill like our LUM Ultrafine Vertical Roller Mill is a top-tier choice. The savings you get from lower power and part replacement costs directly lower your cost per ton and increase profit.

| Equipment Type | Its Job | Pros for Gabbro | Cons to Consider |

|---|---|---|---|

| Rompe mandíbulas | Trituración Primaria | Massive force, simple, reliable, eats big rocks | Output is coarse, needs a second stage |

| Trituradora de cono | Secundario/terciario | Excellent product shape, smart automation, eficiente | Mayor costo inicial, more complex than a jaw |

| Molino vertical | Grinding to sand/fines | Huge energy savings, lower wear, precise control | Higher upfront capital investment |

| Fábrica de bolas | Grinding to ultra-fines | Can get very fine, well-understood technology | High energy use, high wear costs, noisy |

Building a Plant That Lasts: The Big Picture

Designing a gabbro plant involves more than just linking machines together. It’s about creating a unified, strong system. The aim is to get as much as possible of your most valuable product sizes, while constantly reducing your two major expenses: energy and parts wear.

Your process layout should allow for changes. You might need to switch between making concrete aggregate and road base material depending on what the market needs. Using smart screening and flexible conveyor systems makes this possible. And never forget to plan for easy maintenance. Having safe, simple access to replace jaw plates, cone crusher liners, and screen meshes isn’t just nice to have—it’s essential to avoid downtime in a high-wear application like this.

Working with an equipment supplier that provides full support—from plant design and setup to parts and service—is what makes buying equipment a long-term benefit for your business.

A Real Example: Succeeding with Gabbro

Here’s a true story. We had a customer in Scandinavia who was almost ready to give up. Their current Gabbro processing line had constant unplanned stops and very high parts costs. The shape of their product was inconsistent, which limited who they could sell to.

We worked with them to overhaul the entire process. We installed a ruggedTrituradora de mandíbula C6X at the front end and anTrituradora de cono HPT for secondary and tertiary duties. The results were transformative:

- Rendimiento jumped by over 30% because the new equipment was more powerful and, crucially, more reliable.

- Wear part life increased by nearly 40% due to superior metallurgy and optimized crushing chamber designs.

- Product shape became consistently excellent, allowing them to move into premium markets and increase their prices.

This is the real-world impact of applying the right technology to a specificGabro challenge.

What You Should Do Next

Tratamiento gabbro profitably is hard work, but it can definitely be done. The high value of the final product makes it worth investing in serious, well-matched equipment. The goal isn’t to find the lowest-cost machine—it’s to choose the correct machine: technology designed specifically to handle extreme hardness and wear.

From the raw power of a primary rompe mandíbulas to the precision of a trituradora de cono and the efficiency of a vertical roller mill, each piece plays a vital role. Comprensión gabbro and matching your technology to its character is how you build a plant that’s not just operational, but optimally profitable for the long haul.

En SBM China, we live for these challenges. We’re here to be a resource. Tell us about your gabbro project. Let’s work together to configure a solution that turns this tough rock into your foundation for success.