E-mail: [email protected]

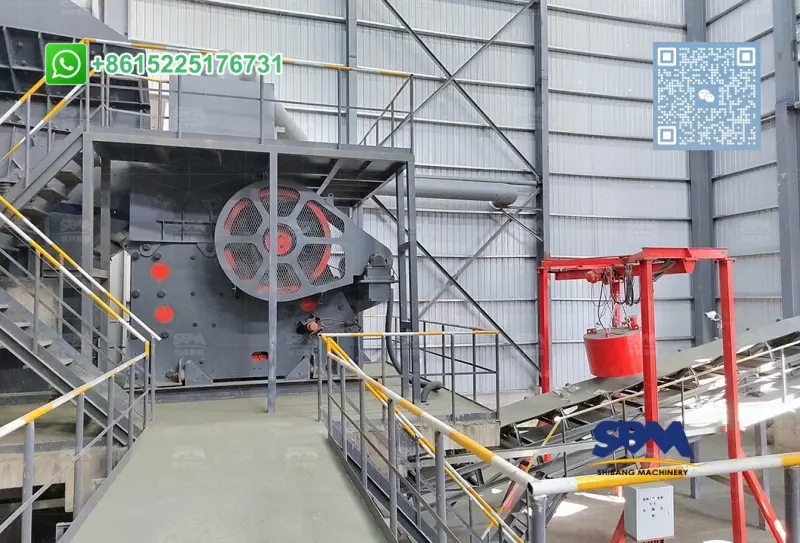

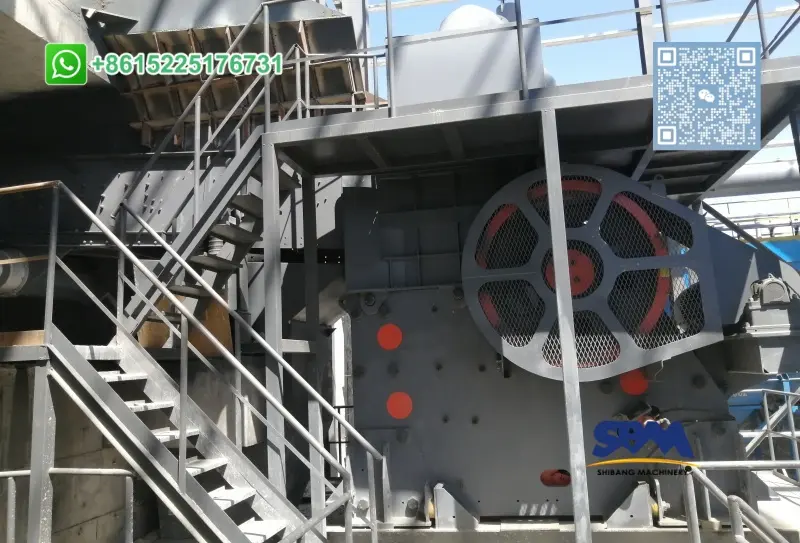

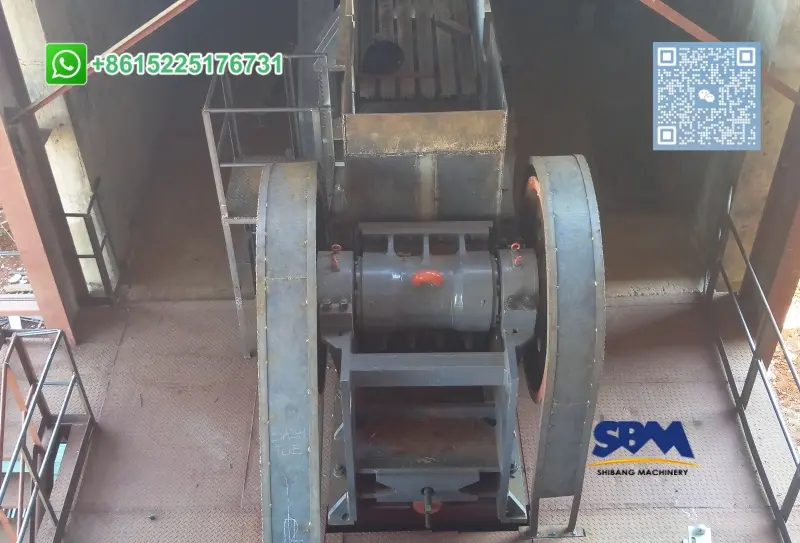

Capacité de broyeur à mâchoire fixe déverrouillée: Du granit canadien au minerai de fer australien

When Quebec’s Lac Bloom iron mine needed to hit 650tph consistently, their fixed jaw crusher setup became the hero—achieving 93% uptime through smart capacity management. This guide breaks downfixed jaw crusher capacity per hour realities across 15 global operations, with actionable tips to maximize your output.

The Capacity Equation: More Than Just Spec Sheets

Canadian Granite Crushing: The Numbers Game

PE600×900 model in Thunder Bay quarry:

| Matériel | Theoretical Capacity | Real-World Avg | Secret Boosters |

|---|---|---|---|

| Granit | 60-160TPH | 138TPH | Laser-aligned CSS + optimized liner rotation |

| Basalte | 75-120TPH | 102TPH | Pre-screening >500mm chunks |

4 Capacity Killers (And How to Fix Them)

1. Le “Hungry Jaw” Paradox

Overfeeding >500mm rocks reduces throughput by 40%.

Solution:

Install grizzly screen with 300mm spacing.

2. Ghost blockage: the invisible killer of the crushing chamber

The material is unevenly accumulated in the crushing chamber, resulting in a 30-50% decrease in actual production capacity, which is common in flaky materials or ores with high clay content.

Solution:

Step-type pre-screening: Install a double-layer vibrating screen (upper layer 300mm screen hole, lower layer 50mm) before the feed inlet. Chile’s Escondida copper mine reduced the blockage rate from 17% pour 3% through this solution.

Cavity modification: Use asymmetric toothed liner (upper tooth pitch 120mm, lower tooth pitch 80mm) to guide the material to flow to the discharge port.

Intelligent purge system: Install compressed air nozzles to automatically clear dead corner accumulation every 15 minutes (Australian FMG iron ore increased production capacity by 22%).

3. Surchauffe des roulements: the silent capacity devourer

When the bearing temperature exceeds 85°C, the equipment automatically slows down, directly resulting in a 40% decrease in production capacity.

Solution:

Mise à niveau de la lubrification: Use NLGI 2 grade polyurea-based grease, which has a temperature resistance 60°C higher than traditional lithium-based grease (data from Quebec granite mine in Canada).

Thermodynamic transformation: Add heat sink fins + forced air cooling system to the bearing seat, and the Turkish Boratas BCK series has a measured temperature reduction of 18°C.

Intelligent monitoring: Install wireless temperature sensors to automatically adjust the feed speed when the temperature difference is greater than 5°C.

4. Vibration imbalance: invisible production capacity loophole

A 0.2mm basic horizontal deviation will cause the vibration value to exceed the standard, forcing the equipment to operate at a reduced frequency, resulting in a fixed jaw crusher capacity loss of 25%.

Solution:

Laser alignment system: Use laser alignment instrument to control the installation accuracy within ±0.05mm/m (the vibration value of the South African gold mine was reduced from 7mm/s to 2.3mm/s after application).

Dynamic counterweight technology: Install adjustable counterweight blocks on the flywheel to balance the eccentric shaft torque in real time (Improving production output stability by 19%).

Elastic foundation transformation: Use rubber-steel composite shock-absorbing base to absorb high-frequency vibration energy (the Vale case in Brazil reduced production capacity fluctuations by 37%).

2025 Tech Upgrades Changing the Game

- AI-Powered CSS Adjustment: Automatically adapts to material hardness (tested in Chilean copper mines)

- Smart Liners: RFID-tagged plates track wear in real-time—replace before failure

- Puissance hybride: Solar-diesel systems cut energy costs by 35% (Australian pilot data)

Capacity vs Cost: The 5-Year Math

| Modèle | Hourly Capacity | 2025 Prix | Cost/Ton |

|---|---|---|---|

| PE400×600 | 16-65TPH | $45k | $0.82 |

| PE600×900 | 60-160TPH | $75k | $0.68 |

| PE1200×1500 | 400-800TPH | $220k | $0.51 |

Compare models in 2025 price guide

Proven Maintenance Hacks for Steady Output

- La règle de 400 heures: Plaques de mâchoire tournantes chaque 400 heures d'opération (extends life by 2.3x)

- Vibration Checkups: Monthly laser alignment keeps hourly output within 5% of spec

- Sweet Spot: 1.2kg EP-2 grease per bearing—overgreasing causes 38% failures

Future-Proof Your Setup

Modular Upgrades

Swap between granite/recycling modes in 4 heures (Norwegian pilot)

Carbon Accounting

New EU regulations reward 650+ tph operations with carbon credits

La ligne de fond: Capacity Is a Dance

As Brazil’s Vale engineers proved: matchingCapacité de broyeur à mâchoire fixe to your actual feed stock (not brochure numbers) can boost profits by 18%. Remember—your crusher’s true potential lies between its specs and your operational wisdom.