E-mail: [email protected]

Pierre de granit écrasé

Maison » Pierre écrasée » Pierre de granit écrasé

Contenu principal

La pierre de granit écrasée est une, Agrégat écologique pour les allées, aménagement paysager, et la construction. Offre un drainage supérieur, 100–250 MPA Force de compression, et dimensionnement polyvalent pour rentable, surfaces stables.

Si vous cherchez un durable, polyvalent, et un matériel écologique pour votre prochain projet, pierre de granit écrasé pourrait être la voie à suivre. Je l'ai entendu de mes clients à maintes reprises. Croyez-moi - ça fait une réelle différence! Ce guide va dans les détails de tout ce que vous devez savoir: des applications et des avantages sociaux aux conseils de dimensionnement. Commençons.

Ce qui est exactement la pierre de granit écrasée?

Le granit écrasé est un agrégat naturel fabriqué en cassant mécaniquement le granit solide en morceaux angulaires. Contrairement au gravier de la rivière arrondie, Ses bords déchiquetés s'entretiennent pour créer une surface stable. Granite écrasée varie en taille à partir d'une poudre fine (“granit altéré”) aux morceaux grossiers. Fait intéressant: Les composants minéraux de granit (comme le quartz et le feldspath) Donnez-lui son apparence marbaine signature et sa durabilité exceptionnelle.

Haut 5 Utilisations pour le granit

- Allées & Routes: Sa compactions le rend idéal pour les couches de base.

- Aménagement paysager: Parfait pour les sentiers de jardin, terrasses, ou couverture de sol décorative.

- Construction: Utilisé dans les mélanges en béton et les systèmes de drainage.

- Contrôle de l'érosion: Stabilise les pentes et les rivages.

- Ballast de chemin de fer: Prend en charge les pistes en raison de ses propriétés de poids et de drainage.

J'ai une fois remplacé mon sentier de l'arrière-cour boueux avecgrognement en granit- les mauvaises herbes nuls et la convivialité toutes temps!

Pourquoi choisir le granit écrasé? Avantages clés

- Durabilité: Résiste à l'altération et aux charges lourdes (résistance à la compression: 100–250 MPA).

- Écologique: 100% naturel et recyclable.

- Drainage: Les lacunes entre les particules empêchent la mise en commun de l'eau.

- Attrait esthétique: Charme rustique avec variations de couleur (gris, rose, ou or).

- Rentable: Moins cher que les pavés ou les dalles solides.

Tailles populaires de gravier de granit et leurs utilisations

Voici un tableau de référence rapide à correspondreGranite en pierre tailles à votre projet:

| Taille (millimètre) | Nom commun | Mieux pour |

|---|---|---|

| 0–5 | Granit décomposé | Chemins, terrains de jeux, amendement du sol |

| 5–10 | Fine Chips en granit | Allées, paillis décoratif |

| 10–20 | Gravier de granit moyen | Base de route, couches de drainage |

| 20–40 | Rocher en granit grossier | Accents d'aménagement paysager, contrôle de l'érosion |

Conseil: Pour les allées, Associez une base de 20 à 40 mm avec une couche supérieure de 5 à 10 mm pour la douceur!

Comment trouver la qualité de granit écrasé de qualité?

Pas tousgranit écrasé est créé égal! Lors de l'achat:

- Vérifier la gradation: Assurer des tailles de particules uniformes (Demandez des rapports d'analyse de tamis).

- Vérifiez la dureté: Opter pour du granit avec >6 Dureté mohs (Comme les carrières de SBM China).

- Considérez la couleur: Faites correspondre l'esthétique de votre projet - par exemple., Gris pour les jardins modernes, rose pour tons chauds.

En dehors de cette, Nous pouvons également utiliser un écrasement manuel ou des brasseurs de mâchoire (pour les agrégats grossiers) et concasseurs à marteaux (pour les agrégats fins) pour écraser le granit ou d'autres minerais.

Pourquoi les concasseurs offrent une pierre de granit écrasée supérieure?

Contrairement à la violage à la main, Les concasseurs mécaniques s'assurent:

✅Taille cohérente des particules (critique pour le compactage et le drainage).

✅Fragments angulaires (Stabilité entrelacée).

✅Poussière / débris minimale (via des écrans intégrés ou des filtres à air).

✅Sortie évolutive (de la poudre de granit décomposée à la base de la route de 40 mm).

3 Types de concasseur pour chaque échelle de projet

| Taper | Échelle du projet | Saisir | Sortir | Mieux pour | Pourboire / piratage | Coût |

|---|---|---|---|---|---|---|

| Broyeurs de mâchoire portables | Projets à petit médium | Boulders de granit brut (≤ 500 mm) | Agrégat grossier (10–40 mm) | Recyclage sur place des déchets de démolition ou des restes de carrière | Ajouter un écran vibrant pour séparer les amendes (0–5 mm) pour les voies | Loyer pour ~ 200 $ / jour (Idéal pour les allées / aménagement paysager) |

| Concasseurs à cône | Production moyenne | Morceaux précusés (≤ 150 mm) | Gravier moyen uniforme (5–20 mm) | Projets à volume élevé nécessitant une gradation précise (Par exemple, ballast de chemin de fer) | Associez le système de suppression des poussières pour réduire l'exposition à la silice | – |

| Concasseurs à percussion | Agrégat fin & Formes de spécialité | Pièces de granit moyen (≤ 100 mm) | Puces de forme cubique (3–10 mm) ou granit décomposé (0–5 mm) | Mélanges décoratifs de gravier ou de béton nécessitant des bords lisses | – | – |

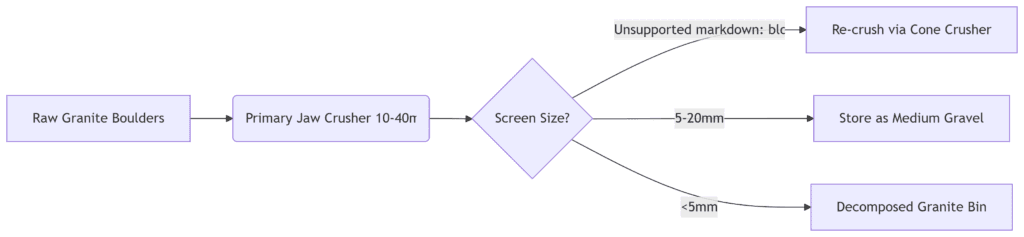

Crusher Workflow: De la roche brute aux agrégats premium

Suivez cette séquence pour une qualité optimale:

Note: Testez toujours la sortie avec un kit de tamis - ajuster les paramètres du concasseur si >15% Les particules s'écartent de la taille de la cible.