Surel: [email protected]

Bagaimana Jaw Crusher Speed Pengaruh Produktivitas? Panduan komprehensif

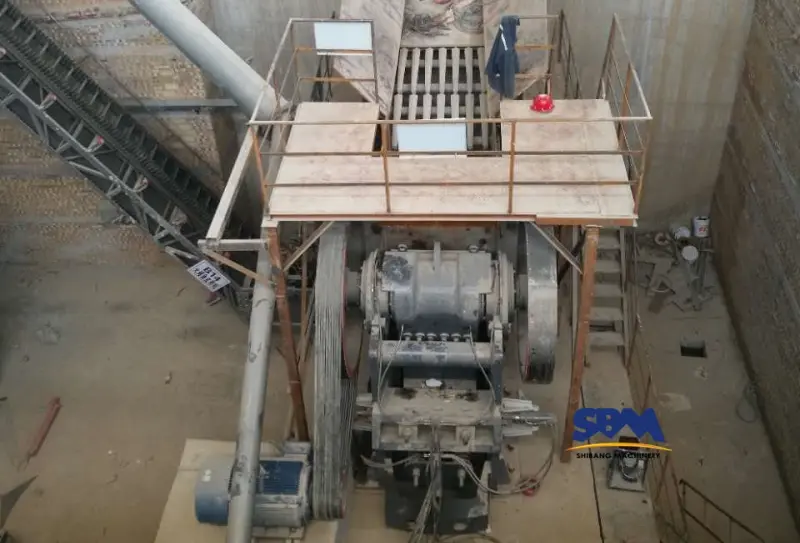

Jawang adalah peralatan landasan di industri pertambangan dan agregat, dengan kecepatan operasional mereka bermain a peran penting dalam tingkat produktivitas dampak. Di mesin SBM, kita 25 tahun keahlian teknik mengungkapkan hal itu Mengoptimalkan kecepatan crusher dapat meningkatkan output dengan 15-30% Sambil mengurangi biaya keausan. Panduan ini mengeksplorasi sains di balik penyesuaian kecepatan crusher dan strategi implementasi praktis.

Hubungan mendasar: Kecepatan Crusher vs Kapasitas Produksi

Memahami RPM Poros Eksentrik

Itu Kecepatan rotasi poros eksentrik (diukur dalam RPM) mendikte:

- Jumlah siklus penghancuran per menit

- Waktu tinggal material di ruang penghancuran

- Pola distribusi ukuran partikel

SBM PE Series Jaw Crushers fitur Pengaturan RPM yang dapat disesuaikan dari 220 ke 330, memungkinkan operator untuk menyempurnakan kinerja untuk bahan yang berbeda seperti granit (250-280 RPM) versus batu kapur (300-320 RPM).

Kurva korelasi kecepatan-throughput

[Grafik kecepatan vs crusher vs throughput]

(Deskripsi gambar: Puncak produktivitas di 280 RPM untuk aplikasi hard rock di SBM Penghancur Rahang C6X model)

Data lapangan kami menunjukkan:

- Di bawah 240 RPM: 22% Kapasitas kurang dimanfaatkan

- 240-300 RPM: Zona produksi optimal

- Di atas 320 RPM: 18% Penurunan efisiensi karena keausan prematur

Tindakan penyeimbang: Strategi optimasi kecepatan

Pengaturan kecepatan khusus material

| Jenis material | RPM yang direkomendasikan | Dorongan produksi |

|---|---|---|

| Basal | 260-280 | 27% vs standar |

| Konkret | 290-310 | 33% efisiensi |

| Batu pasir | 270-290 | 19% Keuntungan output |

Sistem Intelli-Crush SBM secara otomatis menyesuaikan kecepatan berdasarkan umpan balik kekerasan material waktu nyata, memelihara Produktivitas puncak di berbagai kondisi pakan.

Pertimbangan Konsumsi Energi

Sedangkan RPM yang lebih tinggi meningkatkan output per jam, Tes kami menunjukkan:

- Setiap 10 Peningkatan RPM Di luar optimal mengurangi efisiensi energi dengan 5.7%

- Pencocokan kecepatan yang tepat dapat menghasilkan 18-22% penghematan daya

- SBM Crushers mencapai 3.8 Konsumsi energi KWH/t pada kecepatan yang dioptimalkan VS 4.9 kWh/t at max rpm

Dampak umur panjang: Kecepatan vs keausan komponen

Komponen keausan kritis yang dipengaruhi oleh RPM

- Piring sakelar: 40% Pakaian lebih cepat di 300+ RPM

- Rahang meninggal: Kecepatan tinggi meningkatkan abrasi 28%

- Bantalan: Tuntutan pelumasan yang tepat meningkat secara eksponensial di atas 280 RPM

SBM membahas hal ini:

- Piring rahang berbentuk U yang dipatenkan dengan 35% Umur yang lebih lama

- Sistem pelumasan multi-poin

- Soft yang dikendalikan VFD mulai mengurangi stres mekanik

Konten terkait: Komponen crusher rahang utama dijelaskan: Desain, Fungsi & Peduli

Kiat optimasi praktis dari insinyur SBM

Kalibrasi kecepatan tiga langkah

- Melakukan tes kekuatan kompresi material

- Mulailah dari RPM dasar yang direkomendasikan pabrikan (SBM menyediakan bagan khusus material)

- Menyesuaikan 5 Penambahan rpm saat memantau:

- Gradasi produk

- Draw power

- Tingkat getaran

Solusi pemantauan lanjutan

Trek Sistem IoT IoT SmartCrush kami:

- Throughput real-time (th)

- Tingkat keausan liner

- Konsumsi energi per ton

- Analisis Harmonik Getaran

Operator menerima rekomendasi penyesuaian kecepatan otomatis melalui algoritma pemeliharaan prediktif, memelihara 95%+ efisiensi operasional.

Studi kasus SBM: Optimalisasi RPM di Granite Quarry

Klien: Zhejiang Agregat Co., Ltd

Tantangan: 12% Kekurangan produksi dengan ukuran produk yang tidak konsisten

Larutan:

- SBM C6X160 Jaw Crusher

- Mengimplementasikan kontrol kecepatan bertahap:

- Penghancuran primer: 265 RPM

- Pengurangan Sekunder: 285 RPM

Hasil:

✓ 31% peningkatan produksi (dari 220t/jam hingga 288t/jam)

✓ 17% Pengurangan frekuensi penggantian pelat rahang

✓ 22.5 Penghematan energi KWH/T.

Kontrol Kecepatan Presisi = Produktivitas Maksimalkan

Mengoptimalkan Kecepatan operasional jaw crusher membutuhkan menyeimbangkan banyak faktor – karakteristik material, output yang diinginkan, dan umur panjang peralatan. Solusi Penghancuran Cerdas Mesin SBM mengintegrasikan optimasi kecepatan langsung ke dalam kontrol mesin, memungkinkan operator untuk secara konsisten mencapai Efisiensi produksi puncak sambil meminimalkan biaya operasional. Hubungi tim teknis kami hari ini untuk a Analisis Optimalisasi Kecepatan Crusher Gratis disesuaikan dengan aplikasi spesifik Anda.