ईमेल: [email protected]

कचरा पासून संसाधनांपर्यंत: जगभरात जबडा क्रशर कंक्रीट रीसायकलिंगमध्ये क्रांती कशी करतात

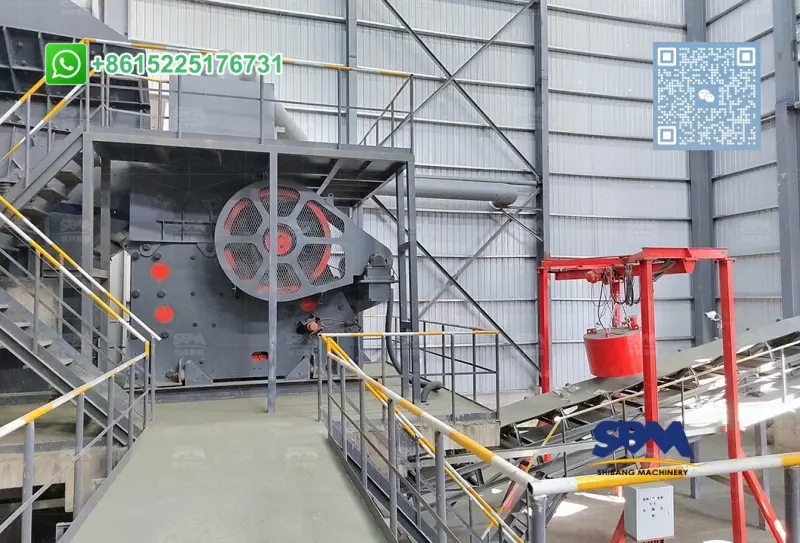

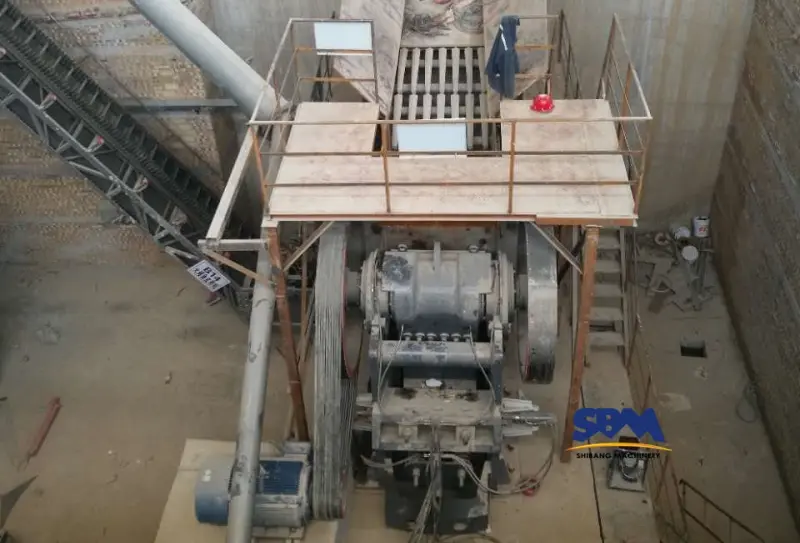

हे चित्र: बर्लिनमधील एक पाडलेला ऑफिस टॉवर नवीन इको-फ्रेंडली हाऊसिंग कॉम्प्लेक्सचा पाया बनला आहे. टेक्सासमधील कोसळलेला पूल महामार्ग दुरुस्तीसाठी कच्चा माल प्रदान करतो. This isn’t sci-fi—it’s the power of modernjaw crushers in recycling concrete and demolition waste. Let’s explore how this technology is turning 230 million tons of annual global construction waste into valuable assets.

The Concrete Recycling Challenge (and Why Jaw Crushers Win)

समस्या 1: द “Dirty Secret” of Demolition

Concrete waste often contains rebar, लाकूड, and even hazardous PAHs. Traditional crushing methods struggle with contamination.

Jaw Crusher Solution

Modern units likeSBM’s C6X series feature:

- Magnetic separators for automatic rebar removal

- Dust suppression systems meeting EU emission standards

- Hardox® steel jaws crushing 500MPa concrete

जागतिक यशोगाथा

केस स्टडी 1: London’s Crossrail Project

Used mobile jaw crushers to process 3.2M tons of tunnel spoil:

| मेट्रिक | परिणाम |

|---|---|

| Recycled Aggregate | 92% of total waste |

| Cost Savings | £18M vs landfill |

| CO₂ Reduction | Equivalent to 7,500 car-years |

केस स्टडी 2: Dubai’s Sustainable Skyscrapers

Stationary jaw crushers process 800t/day of demolition debris for:

- Structural concrete (40MPa grade)

- Landscaping gravel

- Road base materials

Optimizing Your Setup: Pro Tips

फीड आकार बाबी

साठीefficient gravel production:

- Pre-screen debris >500मिमी

- Adjust CSS to 50-75mm for optimal shape

Maintenance Hacks

Avoidcommon failures:

- प्रत्येक वेळी जबडा फिरवा 400 ऑपरेटिंग तास

- Use laser alignment for 0.2mm precision

The Technology Edge: 2025 Innovations

- AI-Powered Sorting: Real-time material analysis via camera systems (tested in Netherlands recycling plants)

- Hydro-Crush Tech: Water-assisted crushing reduces dust by 70% (patented by SBM)

Choosing Your Champion: PE vs C6X Series

पीई मालिका

साठी सर्वोत्तम:

- Small-scale recycling (<200t/day)

- Temporary urban demolition sites

C6X मालिका

साठी सर्वोत्तम:

- Mining-level volumes (>1,000t/day)

- High-abrasion concrete with rebar

अजूनही खात्री नाही? Use ourinteractive selector tool.

Regulatory Smarts: Staying Compliant

Key global standards for recycled aggregates:

- EU: EN 12620 (max 1% lightweight impurities)

- USA: ASTM D2940 (gradation requirements)

- Germany: R-Beton certification

Future Forecast: द 2030 Recycling Landscape

सहnext-gen jaw crushers, experts predict:

- 95% concrete recycling rates in EU cities

- 50% reduction in aggregate mining

- Carbon-negative concrete production via CO₂ injection tech

निष्कर्ष: Crushing the Linear Economy

From Berlin to Boston, jaw crushers are proving that demolition waste is just mislabeled raw material. As SBM’s R&D lead puts it: “The best recycling plants aren’t factories—they’re the jaws of progress.”

मुख्यालय कार्यालय

Whatsapp:+8615225176731

ईमेल: [email protected]

पत्ता: नाही. 1688, गावके पूर्व रस्ता, पुडोंग नवीन जिल्हा, शांघाय, चीन.

संकेतस्थळ: https://www.mill-sbm.com/