Электронная почта: [email protected]

Демистификация компонентов дробилки челюсти для пиковой производительности

Челюстные дробилки - бесспорные рабочие лошадь первичного сокрушительного. Их грубая простота легендарна. Но что действительно способствует их неумолимой накапливаемой способности? Это синергия их ядра Компоненты дробилки челюсти. Захватывание этих компонентов выходит за рамки простого технического разговора; Это важно для увеличения времени безотказной работы, эффективность, и долговечность всей вашей сокрушительной установки. Давайте представим эти критические части. Давайте отбросим занавес на этих жизненно важных элементы.

Компоненты ключевой челюсти: Ваше сокрушительное ядро

Каждый зубодробилка, мордоворот полагается на набор фундаментальныхносить детали и структурные элементы, работающие на концерте. Вот разрушение существенногоЧеловеки из челюсти:

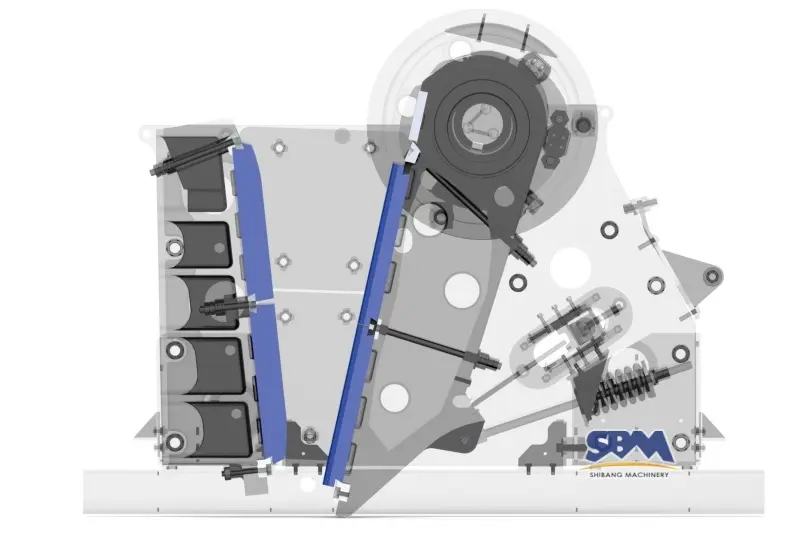

1. Могущественная челюсть умирает (Сокрушительные челюсти / Щеки пластины):

- Функция: Это буквальная точка контакта. Один фиксированный и один подвижный челюстная тарелка образуйте дроблентную камеру, где скала встречается с сопротивлением. Они несут основную тяжесть истирания и воздействия.

- Материальные вопросы: Обычно сделано из супер жесткой марганцевой стали, спроектирован для замены при ношении. Их профиль (плоский, гофрированный, или зубчатый) значительно влияет на конечный размер продукта и форму.

- Почему они имеют значение: Изношенная челюсть умирает эффективность дробления, увеличить потребление энергии, и привести к негабаритному продукту. Regular inspection and timely replacement are non-negotiable for consistent output.Мы видели, как операции поворачивались, просто придерживаясь дисциплинированного графика проверки Jaw Die.

2. Питман: Движущая сила:

- Функция: Это основной компонент движения. Подключен непосредственно к эксцентричному валу, Питман передает мощное возвращение движения в подвижную челюсть, умирайте. Думайте об этом как руку дробилки.

- Строительство: Надежный, тяжелый кастинг, спроектирован, чтобы противостоять огромным циклическим напряжениям. Его целостность имеет первостепенное значение для безопасной и плавной работы.

- Почему это важно: Треснутый или поврежденный питман означает катастрофический сбой и значительное время простоя. Обеспечение правильного выравнивания и избегание некнусованного материала (бродячие железные) имеет решающее значение для долголетия Pitman.

3. Переключение(с): Стража безопасности & Ход настройка:

- Функция: Это критическое компонент служит двойной цели:

- Безопасность: Действует как саблин. Если в камере попадает ненадежный объект, Пластина переключения предназначена для сначала сломаться, Защита питмана, подшипники, и кадр от тяжелого повреждения.

- Поддерживать: Обеспечивает место для нижнего конца питмана и помогает определить ход дробилки.

- Почему это важно: Это встроенный предохранитель вашей дробилки. Никогда не заменяйте сломанную пластину с переключением на одну из более сильных материалов - ее цель - безопасно провалиться! Я вспоминаю, как менеджер сайта вздыхает с облегчением после того, как большой зуб с бедой стоил только для переключателя, не в целом.

Связанное содержимое: Сингл -переключатель против двойной переключатели челюсти: Быстрое сравнение

4. Эксцентричный вал & Подшипники: Сердцебиение:

- Функция: Эксцентричный вал - это вращающийся ядро, которое преобразует вращательное движение двигателя в возвратно. Большой, тяжелые роликовые подшипники поддерживают этот вал, обработка массивных радиальных и нагрузочных нагрузок.

- Почему они имеют значение: Правильная смазка и защита от пыли и загрязнения абсолютно важны. Неудача несущей отказа является одним из самых дорогих и трудоемких ремонтов на челюстной дробилере. Регулярный анализ жира (если это применимо) и дивиденды по инспекции бдительности.

5. Кадр: Непрерывное фундамент:

- Функция: Это костяка дробилки. Обычно тяжелый, Жесткая стальная конструкция (часто сфабриковано или отлиту), В нем есть все остальные компоненты и поглощает дробленные силы.

- Почему это важно: Скомпрометированный выравнивание и производительность, неровная одежда, и потенциальные сбои являются прямыми результатами взломанной или искаженной рамы. Следовательно, обеспечение долгосрочной надежности требует надежного дизайна рамки-отличительной черты дробилок SBM, известных своей структурной целостностью.

6. Маховик: Хранение энергии & Плавная операция:

- Функция: Расположен на обоих концах эксцентричного вала, Эти тяжелые колеса накапливают кинетическую энергию в невозмутимой фазе цикла и разряжают ее во время дробления. Это сглаживает пики спроса на мощность и помогает поддерживать постоянный импульс.

- Почему они имеют значение: Эти компоненты значительно повышают энергоэффективность и уменьшают нагрузку на приводной двигатель. Достижение требований к бегу без вибраций правильно сбалансированных махоловков.

Связанное содержимое: Ключевые компоненты дробилки объяснены: Дизайн, Функция & Уход

Почему понимание частей дробилки челюсти имеет решающее значение

Зная этоКомпоненты дробилки челюсти внутри и снаружи не только для механики. Это упрощает все участники:

- Операторы: Может обнаружить знаки раннего износа или смещения (например, необычные шумы, Изменения размера продукта, повышенная вибрация) Перед эскалацией.

- Команды по техническому обслуживанию: Может спланировать упреждающие замены части (как челюсти умирает или переключают тарелки) во время запланированного времени простоя, Избегание дорогостоящих незапланированных сбоев. Знание правильных процедур для таких задач, как изменение умираний челюсти или проверка зазоров подшипника имеет решающее значение.

- Покупка: Обеспечивает правильную замену качества носить детали поставляются, баланс затрат на производительность и долговечность. Выбор OEM или сертифицированных совместимых деталей часто оказывается более экономичным долгосрочным.

- Управление: Принимает осознанные решения о бюджетах на обслуживание, машина долговечность, и общая эффективность раздавтной схемы.

Максимизация срока службы компонента: Практические советы

- Кормить справа: Убедитесь, что материал находится в рамках разработанной дробилки и предела размера и размера. Используйте Grizzlies или Slocpers, чтобы удалить штрафы и предотвратить упаковку. Задыхание дробилки - все равно что попросить ее провести марафон в щуканом песке - неэффективно и разрушительный.

- Смазать религиозно: Следуйте графику смазки производителя тщательно для подшипников и сиденья переключения. Используйте рекомендуемый смазка/тип масла и количество.

- Мониторинг износа: Регулярно измеряйте толщину челюсти и проверьте пластины для переключения на трещины. Вести записи, чтобы предсказать интервалы замены.

- Избегайте бродяги: Инвестировать и поддерживать эффективные системы обнаружения и удаления металлов (магниты, детекторы). Один кусок стали может нанести ущерб.

- Используйте качественные детали: Выберите высококачественное, Правильно спроектированные замены. Низший дробление деталей носить быстрее, уменьшить выход, и может нанести вторичный ущерб.

- Проконсультируйтесь с экспертами: Используйте знания вашего производителя дробилки или авторитетных поставщиков услуг, таких как SBM. Они предлагают бесценное руководство по оптимизации и техническому обслуживанию, специфичным для вашей машины.

Синергия силы

В конечном счете, Дробилка челюсти так же надежна, как и ее отдельные компоненты. Жизненно важные части, такие как сакральная плита, Убийная челюсть умирает, и вождение Питман каждый внес свой вклад значительно. По -настоящему понимая эти основные части - их роли и как их поддерживать - вы разблокируете согласованность, эффективный, и экономически эффективное сокружение прочных материалов. Ключевое различие между плавным, прибыльная операция и одна из страданий простоя заключается в разумном управлении этими основополагающими компонентами. Стремитесь держать их беспрепятственно вместе!