E-posta: satış@mill-sbm.com

Pik performans için çene kırıcı bileşenleri

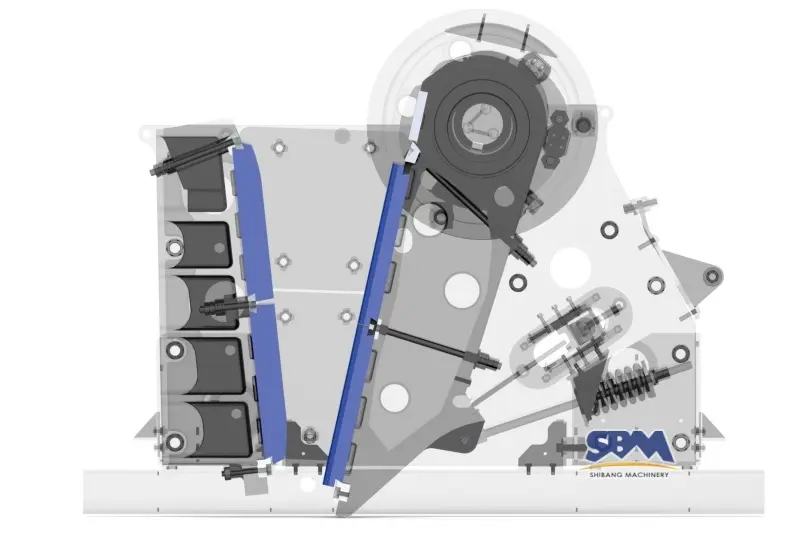

Çene kırıcıları, birincil ezmenin tartışmasız işlerinidir. Sağlam sadelikleri efsanevi. Ama onların amansız kaya kırma yeteneklerine gerçekten güç veren şey? It’s the synergy of their core jaw crusher components. Grasping these components goes beyond mere technical talk; it’s essential for boosting uptime, yeterlik, and the longevity of your entire crushing setup. Let’s unveil these critical parts. Let’s pull back the curtain on these vital elements.

Key Jaw Crusher Components: Your Crushing Core

Her çene kırıcı relies on a set of fundamental wear parts and structural elements working in concert. Here’s a breakdown of the essential jaw crusher parts:

1. The Mighty Jaw Dies (Crushing Jaws / Cheek Plates):

- İşlev: These are the literal point of contact. One fixed and one movable çene plakası form the crushing chamber where rock meets resistance. They bear the brunt of the abrasion and impact.

- Material Matters: Typically made from super tough manganese steel, designed to be replaced when worn. Their profile (flat, corrugated, or toothed) significantly impacts the final product size and shape.

- Why They Matter: Worn jaw die drastically reduce kırma verimliliği, increase energy consumption, and lead to oversized product. Regular inspection and timely replacement are non-negotiable for consistent output. We’ve seen operations turn around just by sticking to a disciplined jaw die inspection schedule.

2. The Pitman: The Driving Force:

- İşlev: This is the main moving component. Connected directly to the eccentric shaft, the pitman transmits the powerful reciprocating motion to the movable jaw die. Think of it as the crusher’s arm.

- Yapı: A robust, heavy-duty casting, engineered to withstand immense cyclical stresses. Its integrity is paramount to safe and smooth operation.

- Why It Matters: A cracked or damaged pitman means catastrophic failure and significant downtime. Ensuring proper alignment and avoiding uncrushable material (tramp iron) is crucial for pitman longevity.

3. The Toggle Plate(S): Safety Sentinel & Stroke Adjuster:

- İşlev: This critical component serves a dual purpose:

- Emniyet: Acts as a sacial link. If an uncrushable object enters the chamber, the toggle plate is designed to break first, protecting the pitman, rulmanlar, and frame from severe damage.

- Destek: Provides a seat for the lower end of the pitman and helps define the crusher’s stroke.

- Why It Matters: It’s your crusher’s built-in fuse. Never replace a broken toggle plate with one made from stronger material – its purpose is to fail safely! I recall a site manager breathing a huge sigh of relief after a large stray bucket tooth only cost them a toggle plate, not a whole rebuild.

İlgili İçerikler: Tek geçiş vs çift geçiş çene kırıcılar: Hızlı bir karşılaştırma

4. Eccentric Shaft & Rulmanlar: The Heartbeat:

- İşlev: The eccentric shaft is the rotating core that converts the motor’s rotary motion into the pitman’s reciprocating motion. Büyük, heavy-duty roller bearings support this shaft, handling massive radial and thrust loads.

- Why They Matter: Proper lubrication and protection from dust and contamination are absolutely vital. Bearing failure is one of the most expensive and time-consuming repairs on a jaw crusher. Regular grease analysis (if applicable) and vigilant seal inspection pay dividends.

5. The Frame: Unyielding Foundation:

- İşlev: This is the crusher’s backbone. Typically a heavy, rigid steel structure (often fabricated or cast), it houses all other components and absorbs the crushing forces.

- Why It Matters: Compromised alignment and performance, uneven wear, and potential failures are the direct results of a cracked or distorted frame. Ensuring long-term reliability therefore demands a robust frame design – a hallmark of SBM crushers known for their structural integrity.

6. Flywheels: Energy Storage & Smooth Operation:

- İşlev: Positioned on both ends of the eccentric shaft, these heavy wheels accumulate kinetic energy in the non-crushing phase of the cycle and discharge it during the crushing stroke. This smooths out power demand peaks and helps maintain consistent momentum.

- Why They Matter: These components greatly enhance energy efficiency and lessen stress on the drive motor. Achieving vibration-free running demands properly balanced flywheels.

İlgili İçerikler: Anahtar çene kırıcı bileşenleri açıklandı: Tasarım, İşlev & Özen

Why Understanding Jaw Crusher Parts is Crucial

Knowing these jaw crusher components inside and out isn’t just for mechanics. It empowers everyone involved:

- Operators: Can spot early wear or misalignment signs (Örn., unusual noises, product size changes, heightened vibration) before escalation.

- Maintenance Teams: Can plan proactive part replacements (like jaw dies or toggle plates) during scheduled downtime, avoiding costly unplanned breakdowns. Knowing the correct procedures for tasks like changing jaw dies or checking bearing clearances is critical.

- Purchasing: Ensures the right quality replacement wear parts are sourced, balancing cost with performance and longevity. Opting for OEM or certified compatible parts often proves more economical long-term.

- Management: Makes informed decisions about maintenance budgets, machine longevity, and overall crushing circuit efficiency.

Maximizing Component Life: Practical Tips

- Feed Right: Ensure material is within the crusher’s designed capacity and size limits. Use grizzlies or scalpers to remove fines and prevent packing. Choking a crusher is like asking it to run a marathon in quicksand – inefficient and damaging.

- Lubricate Religiously: Follow the manufacturer’s lubrication schedule meticulously for bearings and the toggle seat. Use the recommended grease/oil type and quantity.

- Monitor Wear: Regularly measure jaw die thickness and check toggle plates for cracks. Keep records to predict replacement intervals.

- Avoid Tramp Iron: Invest in and maintain effective metal detection and removal systems (magnets, detectors). One piece of steel can wreak havoc.

- Use Quality Parts: Opt for high-quality, properly engineered replacements. Inferior crushing parts wear faster, reduce output, and can cause secondary damage.

- Uzmanlara Danışın: Leverage the knowledge of your crusher manufacturer or reputable service providers like SBM. They offer invaluable guidance on optimization and maintenance specific to your machine.

The Synergy of Strength

Ultimately, a jaw crusher is only as dependable as its individual components. Vital parts like the sacial toggle plate, the resilient jaw dies, and the driving pitman each contribute significantly. By truly understanding these core pieces—their roles and how to maintain them—you unlock consistent, verimli, and cost-effective crushing of tough materials. The key difference between a smooth, profitable operation and one plagued by downtime lies in intelligently managing these foundational components. Strive to keep them working seamlessly together!

Genel Müdürlük

Naber:+8615225176731

E-posta: satış@mill-sbm.com

Adres: HAYIR. 1688, Gaoke Doğu Yolu, Pudong yeni bölge, Şanghay, Çin.

İnternet sitesi: https://www.mill-sbm.com/