E-posta: satış@mill-sbm.com

Çene Plakası Seçim Kılavuzu: Ezme işleminiz için performansı optimize edin

Doğru çene plakalarını seçmek,kırma verimliliği ile 25-40% Değiştirme maliyetlerini azaltırken. Bu kapsamlıÇene Plakası Seçim Kılavuzu Maddi kompozisyonun nasıl olduğunu açıklar, Diş Profili Tasarımı, ve çalışma koşulları plaka uzun ömürlülüğünü belirler. İster C6X çene kırıcı mı yoksa daha eski modeller, Bu içgörüler bilinçli kararlar vermenize yardımcı olacaktır.

Çene plakası seçiminde anahtar faktörler

Malzeme kompozisyon seçimleri

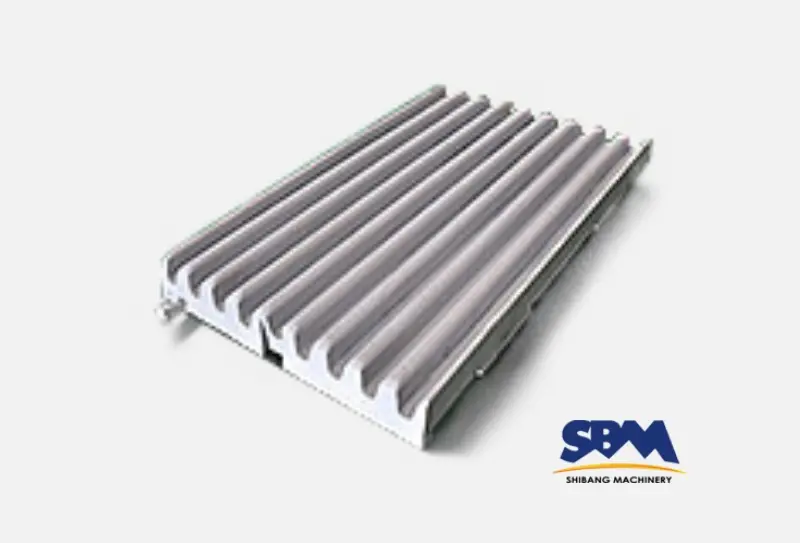

Modern çene plakaları üç birincil malzeme kullanır:

- Manganez çeliği (14-18%): Genel amaçlı için idealtaş ocağı uygulamaları, Değiştirmeden önce 50-70k ton dayanıyor

- Krom demir alaşımı: 30% Granit gibi aşındırıcı malzemelerde daha uzun ömür

- Seramik: Gebeyi azaltır 45% Yüksek silika içerik operasyonlarında

Diş Profili Tasarım Hususları

Plakanın diş konfigürasyonu,Kırıcı'nın çalışma mekanizması:

| Profil Türü | En iyisi | Çıktı Boyut Aralığı |

|---|---|---|

| Dümdüz | Birincil ezme | 150-300 mm |

| Sallanan | İkincil azaltma | 50-120 mm |

| Melez | Karışık malzeme yemleri | 30-150 mm |

4-Adım Seçim Süreci

- Yem malzemesini analiz et: Sertliği test et (Mohs ölçeği) ve aşındırma

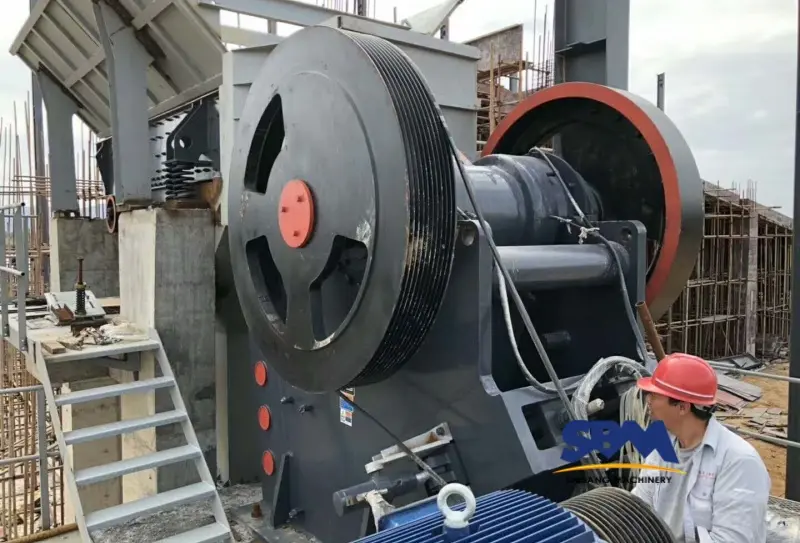

- Kırıcı Türünü Belirle: C6X Serisi çene kırıcı belirli plaka kilitleme sistemleri gerektirir

- Ekonomik ömrü hesaplayın: Başlangıç maliyetini dengeleme ve ton kırıldı/$

- Uyumluluğu doğrulayın: Montaj sistemi boyutlarını kontrol edin (± 2mm tolerans)

Bakım sinerjisi: Plakalar ve Kırıcı Sağlık

Düzgünçene kırıcı bakımı Plaka ömrünü uzatır 60%:

- Her Döndür 200-300 çalışma saatleri

- Doğru CSS ayarlarını koruyun (aşınma desenlerini etkiler)

- Hassas kurulum için lazer hizalama araçlarını kullanın

Vaka çalışması: Granit ocağı optimizasyonu

Brezilyalı bir operasyon elde edildi 32% Maliyet Azaltma:

- Standart MN14'ten MN18CR2 plakalarına geçiş

- İki haftalık aşınma ölçümlerinin uygulanması

- Değiştirmeleri planlı bakım kesintisi ile senkronize etme

Gelişmiş izleme teknikleri

- 3D Kalan kesin kalınlık analizi için tarama takın

- AI ile çalışan aşınma oranı tahmin modelleri

- Malzeme doğrulaması için ultrasonik sertlik testi

Ortak seçim hataları

- 3x daha sık yedekleme ihtiyacı olan ucuz plakalar seçmek

- Malzeme uyumluluğunu görmezden gelmek (Örn., çinko kontaminasyonu)

- Kırıcı kinematik üzerindeki plaka ağırlığı etkileri

Stratejik seçim temettü ödüyor

Hakimiyetçene plakası seçimi Malzemenizi anlamayı gerektirir, makine tipi (C6X modelleri gibi), ve operasyonel hedefler. Elde etmek için bu kılavuzu düzenli önleyici bakımla eşleştirin 18-24 zorlu koşullarda bile ay plaka ömrü. Hatırlamak: Bugün optimal plaka yarın farklı olabilir – Seçimleri büyük malzeme değişiklikleriyle yeniden değerlendirin.