E-mail: [email protected]

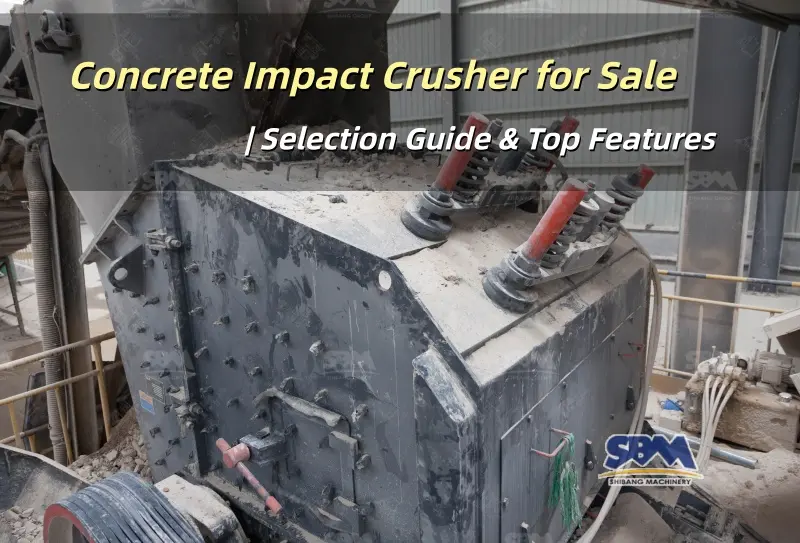

Concrete Impact Crusher for Sale

Why Concrete Impact Crushers?

If you’re running a ready-mix plant, construction demo site, or recycling operation, you know that timely, reliable crushing is non-negotiable. Modernconcrete impact crushers are designed specifically for tough materials like reinforced concrete, Phá hủy chất thải, and aggregate. What sets them apart? They don’t just smash—they transform chunky debris into consistent, cubical aggregate ready for new paving or structural use.

Personal note: As an industry insider, I’ve seen operations save thousands by making the switch to the right impact crusher. The speed, the shape of the product, and the hassle-free running really do make a difference for your bottom line.

How Does an Impact Crusher Work?

Unlike jaw crushers that use pressure, an impact crusher reduces concrete with high-energy blows from a spinning rotor. When the rotor’s blow bars hit the material, two things happen:

- The big chunks break apart in mid-air (primary impact)

- The pieces bounce against impact plates or aprons (secondary impact), getting smaller still

This double impact action means less wear on parts and more high-quality output per hour.

Tip: If you process a lot of rebar, choose a machine with an efficient magnet and hydraulic clearance.

When Does a Concrete Impact Crusher Outperform Other Crushers?

Let’s keep it real: no crusher is perfect for every application. But if you want to crush concrete, with or without rebar, and need a superior cubic shape for your end material, animpact crusher for sale is a top contender. Especially if you’re recycling or require on-site mobility.

Quick Compare:

| Loại máy nghiền | Tốt nhất cho | Typical Output Shape |

|---|---|---|

| máy nghiền hàm | Sơ đẳng, very hard rocks | Phẳng, less cubic |

| Máy nghiền hình nón | Sơ trung, abrasive stone | Well-graded, less cubic |

| máy nghiền tác động | Bê tông, phá hủy, nhựa đường | Cubic/high aggregate |

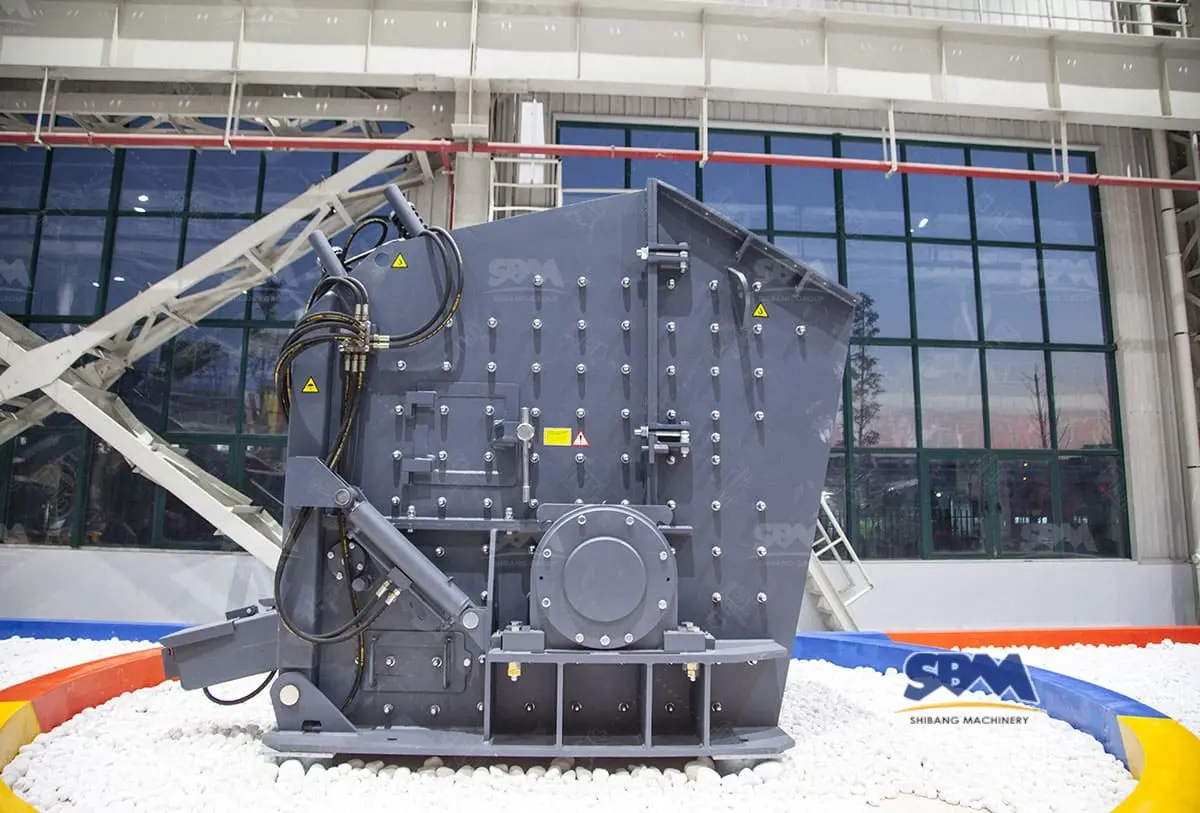

Key Features to Look for in a Concrete Impact Crusher

Buying aconcrete impact crusher for sale isn’t just about specs—it’s about real-life productivity. Here’s what matters most:

- Feed opening size: Bigger means less prep work! (Check your largest material input.)

- Dung tích: Measured in tons/hour. Don’t undersize—future-proof your plant.

- Rotor strength and design: More power = more productivity & longer life.

- Mobility options: Theo dõi (site-to-site) or wheeled (longer moves).

- Output size adjustment: Quick changes for different specs.

- Magnet features: For removing rebar and metals.

- Ease of maintenance: Accessibility saves hours—literally.

- Automation & remote control: Safety and operator convenience.

Concrete Impact Crusher Product Comparisons

Here’s a direct look at some leading models and their main specifications. (Data shown is typical and reference only—always ask for the latest spec sheet when you inquire!)

Comparative Table: Common Impact Crushers for Concrete

| Người mẫu | Inlet Size (mm) | Max Input (mm) | Quyền lực (kW) | Dung tích (quần què) | Tính cơ động |

|---|---|---|---|---|---|

| CI5X1315 | 1540×930 | 600 | 250-315 | 250-350 | Wheeled/Tracked |

| CI5X1415 | 1540×1320 | 900 | 315-400 | 300-450 | Theo dõi |

| PF-1210 | 400×1080 | 350 | 110-132 | 70-120 | Fixed/Mobile |

| PF-1315 | 860×1520 | 500 | 180-260 | 160-250 | Fixed/Mobile |

Want a closer look? Check out detailed spec PDFs and the latest features on https://www.sbmchina.com/.

Factors to Consider When Buying

Choosing aconcrete crushing machine is a big investment—get it right to avoid regrets!

The Big 9 Buying Questions

- What’s your main material type and size? Độ cứng, wetness, and max piece size dictate crusher type and strength.

- Required output per hour? Get realistic about peak and average loads.

- What’s the desired final product size/shape? For road bases, you’ll want consistent aggregate.

- Site conditions: Tight spaces? You may need a compact tracked unit.

- Power source preference: Electric or diesel? Some operations run hybrid models for flexibility.

- Ease of transport and set-up: Especially for contractors who relocate frequently.

- Maintenance needs: Can you swap blow bars quickly? Are parts easy to get?

- Long-term service and warranty: What’s actually covered? Is support available locally?

- Total cost of ownership: Fuel, spares, downtime, tech support—not just sticker price.

Cost Analysis: Price vs. Lifetime Value

Don’t get trapped by “lowest price” mentality. Here’s a fast breakdown of what really drives cost over time:

| Factor | Immediate Cost | Ongoing Cost | Impact on ROI |

|---|---|---|---|

| Machine price | Cao | One-time | Key, but not all |

| Fuel/power efficiency | Varies | Major | Direct savings |

| Wear part lifespan | Varies | Frequent | Longer = lower cost |

| Maintenance/downtime | Hidden | Major | Uptime = more profit |

| After-sale service | Often ignored | Phê bình | Fast fixes = less loss |

Pro tip: Sometimes paying more upfront for a reputable brand and strong local support pays back quickly through uptime and hassle-free running.

Practical Crusher Selection Workflow

Let’s break it down step by step—one bad call can cost months of production.

- Define Your Material: What’s the main concrete/debris type?

- Calculate Throughput Needs: Be honest; over-spec is better than under!

- Compare Crusher Models: Use the tables above and vendor spec sheets.

- Schedule Demo or Site Visit: Always see a similar crusher in action if possible.

- Check Service Credentials: Ask for maintenance & parts lead time. Talk to existing owners.

- Request the Real Cost Sheet: Factor in wear, quyền lực, and labor—not just upfront price.

- Seal the Deal: Negotiate warranty, service, and parts commitments upfront.

Smart Maintenance for Maximum Crusher Life

Here’s how top operators keep impact crushers running profitably for years:

- Routine Inspections: Daily and weekly checks let you spot wear before it turns costly.

- bôi trơn: Don’t skip—the right grease at the right place means fewer breakdowns.

- Blow Bar Management: Rotate/reverse bars as per manufacturer’s advice.

- Keep It Clean: Dust and debris shorten lifespan, especially around bearings and sensors.

- Use Genuine Parts: Knock-offs might save short-term, but cost much more in downtime.

Concrete Impact Crusher FAQs

Q: Will an impact crusher handle hard granite?

A: Đúng, but check model specs for maximum compressive strength and input size. Premium models are designed for everything from limestone to high-strength stone.

Q: Can I process concrete with rebar?

A: Absolutely—with the right rebar removal system (magnet and easy clearing), you’ll get great results.

Q: How do I know what size impact crusher I need?

A: Match the feed opening and rotor to the size of your materials and your throughput targets. More is better—it gives you operating headroom.

Q: Is mobile or stationary better?

A: Mobile for projects that move site-to-site or need easy setup; stationary for high-output, long-term installations.

Q: What should I look for in after-sale support?

A: Warranty clarity, nearby parts/technicians, and easy access to training.

Related Impact Crushers

trụ sở văn phòng

Whatsapp:+8615225176731

E-mail: [email protected]

Địa chỉ: KHÔNG. 1688, Đường Đông Gaoke, quận mới Phố Đông, Thượng Hải, Trung Quốc.

Trang mạng: https://www.mill-sbm.com/