E-mail: [email protected]

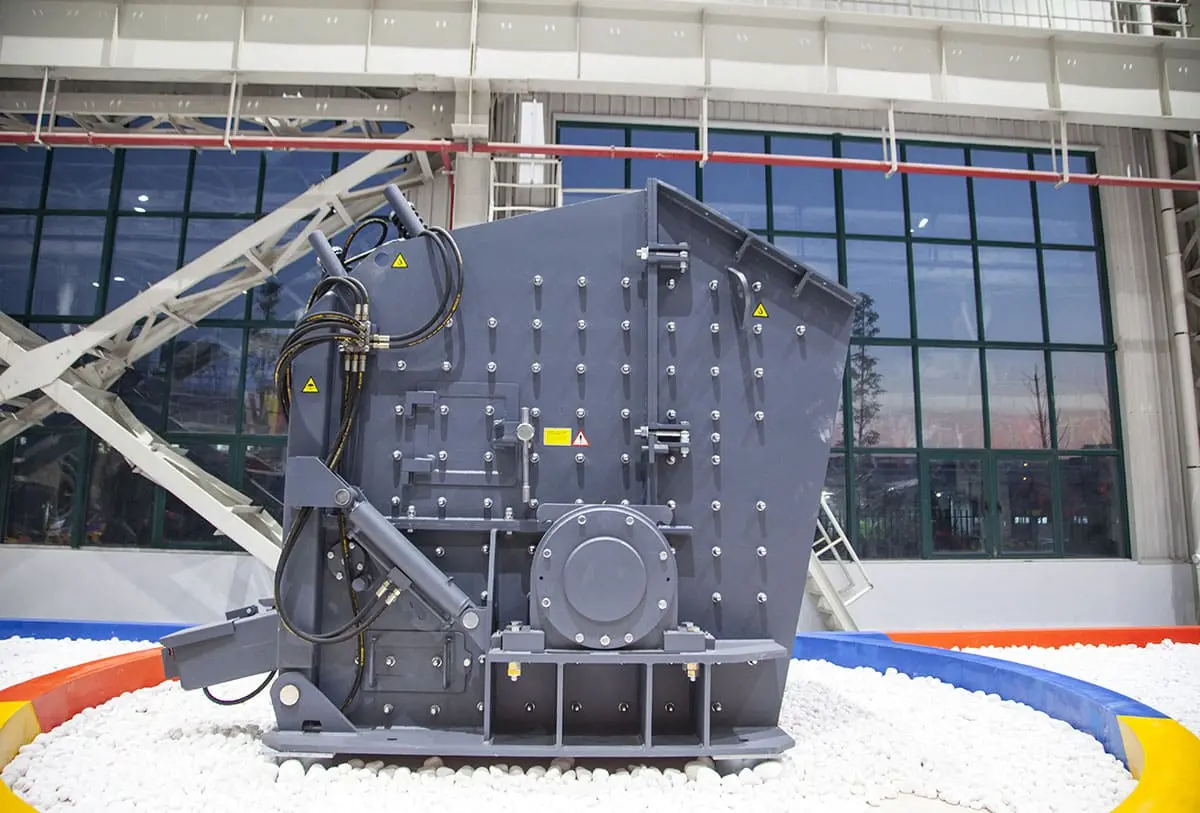

máy nghiền tác động

Máy nghiền tác động là gì?

Máy nghiền tác động là loại máy nghiền đá sử dụng lực tác động tốc độ cao để phá vỡ đá và khoáng chất. Không giống như máy nghiền hàm hoặc hình nón, một máy nghiền tác động đập vật liệu vào một tấm cố định (đôi khi được gọi là tấm chắn hoặc tạp dề tác động), sử dụng rôto quay có gắn thanh thổi hoặc búa.

Được sử dụng cho:

- đá vôi, đá hoa cương, đá bazan, và các khoáng sản khác

- Cát, sỏi, Sản xuất tổng hợp

- Tái chế phá dỡ xây dựng

Tại sao máy nghiền tác động?

Nếu bạn làm trong ngành khai thác mỏ hoặc tổng hợp, việc lựa chọn máy nghiền tác động phù hợp là rất quan trọng—không chỉ đối với sản lượng sản xuất, mà còn vì lợi nhuận và tăng trưởng chung. Với rất nhiều tùy chọn và thông số cần xem xét, đưa ra quyết định sáng suốt có thể là một thách thức. Tôi sẽ giải thích mọi thứ bằng tiếng Anh đơn giản, dựa trên nhiều năm kinh nghiệm giúp khách hàng tìm ra giải pháp lý tưởng của họ.

Chúng tôi sẽ đi sâu vào mọi thứ bạn cần biết: từ những điều cơ bản về máy nghiền tác động đến các mẹo lựa chọn thực tế, những quan niệm sai lầm và vấn đề phổ biến, các loại thiết bị, câu chuyện thành công, và khuyến nghị bảo trì.

Máy nghiền tác động vs. Máy nghiền khác

| Loại máy nghiền | Nguyên tắc | Tốt nhất cho | Ưu điểm chính |

|---|---|---|---|

| máy nghiền tác động | Sự va chạm, sự hao mòn | Đá mềm đến trung bình, cốt liệu, tái chế | Mức giảm cao, hình dạng, điều chỉnh |

| máy nghiền hàm | nén | Cứng, đá mài mòn | Đơn giản, gồ ghề, trọng tải cao |

| Máy nghiền hình nón | nén, cắt | Chất liệu rất cứng, sản phẩm tốt | Kiểm soát sản phẩm giai đoạn cuối |

Máy nghiền tác động hoạt động như thế nào?

Máy nghiền tác động hoạt động bằng cách phá vỡ nhanh chóng các vật liệu như đá, bê tông, và nhựa đường sử dụng những cú va chạm mạnh. Đầu tiên, vật liệu đi vào buồng có rôto quay có gắn thanh kim loại hoặc búa. Khi rôto quay, những thanh này va vào vật liệu và ném nó vào các tấm rắn bên trong buồng, làm cho các mảnh trở nên nhỏ hơn. Hành động này tiếp tục xảy ra khi vật liệu nảy lên giữa các thanh chuyển động, các tấm rắn, và các mảnh khác cho đến khi đủ nhỏ để rơi ra qua khe hở ở đáy máy.

Các bước chính trong hoạt động:

- cho ăn: Vật liệu đi vào qua lỗ nạp hoặc phễu.

- Thầm yêu: Rôto tốc độ cao tấn công vật liệu bằng búa hoặc thanh thổi, phóng nó vào các tấm tác động (tạp dề).

- Sự phân mảnh: Vật liệu bị vỡ do va chạm và nảy lên giữa các tấm và các mảnh khác.

- Phóng điện: Khi các mảnh đủ nhỏ, chúng thoát ra qua cổng xả. Kích thước hạt cuối cùng có thể được điều chỉnh bằng cách thay đổi khoảng cách giữa rôto và các tấm va đập.

Lợi ích của việc sử dụng máy nghiền tác động

| Tính năng | Lợi ích |

|---|---|

| Tỷ lệ nghiền cao | Giảm kích thước hiệu quả hơn, cần ít đường chuyền hơn |

| Hình dáng vượt trội | Sản xuất cốt liệu chất lượng cao với hình khối |

| Cài đặt có thể điều chỉnh | Dễ dàng thay đổi phân loại sản phẩm cho các nhu cầu khác nhau |

| Thiết lập nhanh & di chuyển | Nhiều mô hình bán di động hoặc hoàn toàn di động để sử dụng trang web linh hoạt |

| tiết kiệm chi phí | Đầu tư thấp hơn nhiều lựa chọn thay thế |

| Bảo trì dễ dàng | Truy cập đơn giản để thay đổi và kiểm tra thanh thổi |

Máy nghiền tác động mang lại sự cân bằng giữa hiệu quả và tính linh hoạt mà khó có đối thủ nào trong ngành có thể sánh kịp.

Các tính năng và thông số chính của máy nghiền tác động

Kích thước cánh quạt

- Đường kính Vàchiều dài điều chỉnh lực tác động.

- Rôto lớn hơn = Thông lượng cao hơn & hiệu quả.

Kích thước mở nguồn cấp dữ liệu

- Xác định kích thước hạt tối đa bạn có thể nghiền nát.

- Lỗ nạp lớn hơn = Xử lý vật liệu linh hoạt hơn.

Thanh thổi / Búa

- Nhiều thanh thổi hơn thường tăng hiệu quả.

- Chất liệu của thanh thổi (crom cao, mangan) ảnh hưởng đến tuổi thọ mặc.

Công suất động cơ & Thông lượng

- Tính bằng kilowatt (kW) và tấn/giờ (TPH).

- Đảm bảo mô hình phù hợp với nhu cầu sản xuất dự kiến của bạn.

Điều chỉnh & Điều khiển

- Thủy lực vs. cài đặt thủ công ảnh hưởng đến sự thuận tiện.

- Ổ đĩa tốc độ thay đổi giúp tối ưu hóa sự chuyển màu & mẫu mặc.

Cho tiền boa: Đừng bỏ qua quyền truy cập bảo trì—đó là điều giúp máy nghiền của bạn hoạt động hiệu quả về lâu dài!

Cách chọn máy nghiền tác động phù hợp?

- Biết tài liệu của bạn

- Nó cứng hay mềm? Các mảnh lớn như thế nào khi bắt đầu?

- Chất liệu ướt hoặc thô ráp tạo nên sự khác biệt!

- Xác định nhu cầu đầu ra

- Bạn cần kiếm bao nhiêu tiền mỗi giờ? Cuối cùng bạn muốn miếng kích thước bao nhiêu?

- Cần nhiều lớp hoặc chỉ một?

- Kiểm tra các hạn chế của trang web

- Di động hoặc cố định? Có bao nhiêu không gian có sẵn?

- Yêu cầu về nguồn điện và bụi/âm thanh?

- Ngân sách cho tổng chi phí

- Nhìn xa hơn giá dán nhãn—hãy nghĩ đến các bộ phận, sửa chữa, và bất kỳ thời gian cần thiết thêm.

- Review Uy Tín Thương Hiệu Và Dịch Vụ Hậu Mãi

- Chọn nhà sản xuất có độ tin cậy đã được chứng minh và hỗ trợ tại địa phương. SBM là một ví dụ điển hình ở Châu Á với đầy đủ dịch vụ hỗ trợ.

Máy nghiền tác động SBM

Những lầm tưởng phổ biến & Câu hỏi thường gặp

Huyền thoại 1: Máy nghiền tác động bị mòn quá nhanh.

- Sự thật: Với hợp kim hiện đại và điều khiển thông minh hơn, tỷ lệ hao mòn thấp hơn nhiều so với mười năm trước.

Huyền thoại 2: Chỉ thích hợp với đá mềm.

- Sự thật: Nhiều máy nghiền tác động xử lý đá có độ cứng trung bình và thậm chí một số loại đá cứng—kiểm tra kích thước rôto và thông số năng lượng!

Câu hỏi thường gặp 1: Điều gì ảnh hưởng đến công suất máy nghiền tác động nhất?

- Trả lời: Kích thước nguồn cấp dữ liệu, phân phối thức ăn, đường kính cánh quạt, và quyền lực đều đóng vai trò quan trọng.

Câu hỏi thường gặp 2: Nên mua mô hình điều chỉnh thủy lực hay bằng tay thì tốt hơn?

- Trả lời: Mô hình thủy lực cung cấp nhanh hơn, thay đổi an toàn hơn và tinh chỉnh tốt hơn.

Trường hợp máy nghiền tác động liên quan

BẢO TRÌ & Mẹo vận hành

- Kiểm tra thanh thổi thường xuyên: Thay thế các thanh bị mòn trước khi hiệu suất giảm xuống.

- Nạp đều khắp rôto: Ngăn chặn sự mài mòn không đồng đều và duy trì chất lượng.

- Điều chỉnh cài đặt xả: Tinh chỉnh tốc độ và khoảng cách cho các mục tiêu phân cấp.

- Làm sạch xung quanh các cổng bụi: Giảm thời gian ngừng hoạt động & cải thiện sự an toàn.

- Xem bảng điều khiển Vibro: Sử dụng tính năng tự động hóa tích hợp nếu có thể để điều chỉnh theo thời gian thực.

- Bảo trì tài liệu: Giữ nhật ký để phát hiện xu hướng và tối ưu hóa lịch trình.

Mẹo cá nhân: Nhiều khách hàng bỏ qua việc bảo trì vì nghĩ rằng thật lãng phí thời gian. Nhưng việc bảo trì theo kế hoạch luôn tiết kiệm tiền và đỡ đau đầu về sau!

trụ sở văn phòng

Whatsapp:+8615225176731

E-mail: [email protected]

Địa chỉ: KHÔNG. 1688, Đường Đông Gaoke, quận mới Phố Đông, Thượng Hải, Trung Quốc.

Trang mạng: https://www.mill-sbm.com/