Email: [email protected]

Several Steps And Required Equipment For Feldspar Mining And Processing

Feldspar mining and processing from the Earth’s crust is a challenging process that is involved in feldspar mining and processing. Due to its characteristic properties, including high hardness, abrasion resistance, and capacity to withstand high temperatures, the feldspar mineral group is an extensively used in a number of industries. The steps in the mining and processing of feldspar include exploration, extraction, crushing, grinding, separation, purification, and packaging. This article will examine feldspar mining and processing, its use in many industries, and the business’s effects on the environment and society.

What is feldspar mining?

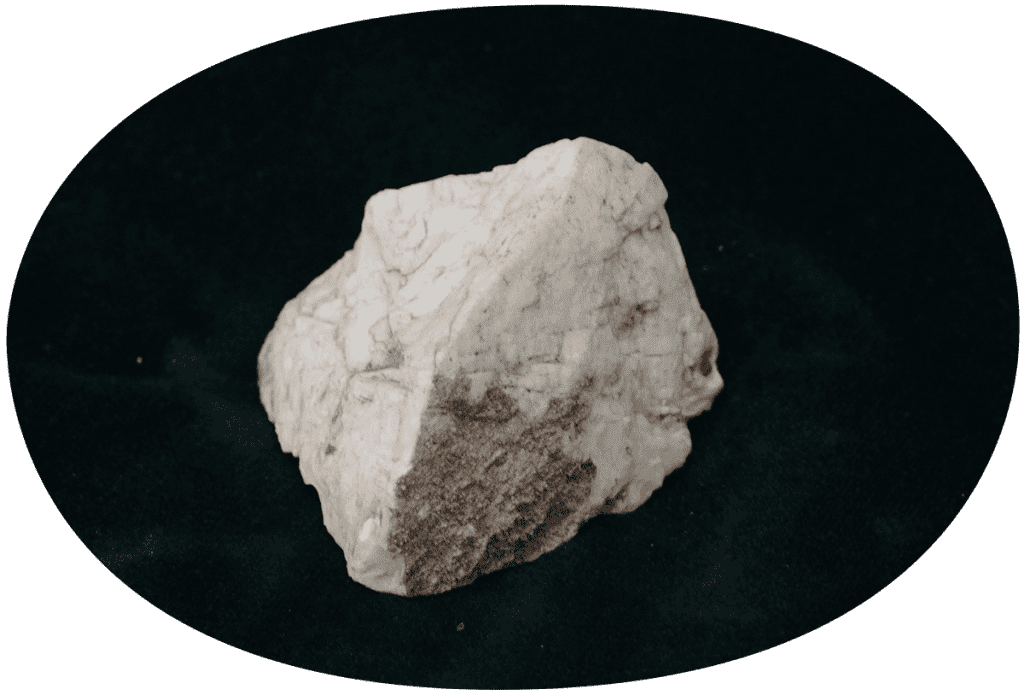

Feldspar is a mineral group widely present in the Earth’s crust. It is one of the most plentiful minerals in the Earth’s crust, accounting for up to 60% of its total weight. The color of feldspar is from white to blue or red, its hardness is 5-6.5, and its density is 2.54-2.75 g/cm3. Feldspar is a rock-forming mineral made up of aluminum, potassium, sodium, and silicon. It’s most abundant in igneous, metamorphic, and sedimentary rocks.

Feldspar has many different applications, including ceramics, glass and building materials. Its uses are also in the manufacture of abrasives, enamel, and as a filler for various industrial products. Feldspar acts as a flux in the ceramic industry. It helps lower the melting point of ceramics, making them easier to shape.

Plagioclase feldspar and potassium feldspar are the two primary varieties of feldspar. Plagioclase feldspar is normally white or gray, while potassium feldspar is frequently pink or white. In the Earth’s crust, feldspar is a significant mineral that is essential to several geological processes.

So, what is the process of feldspar mining and processing?

Feldspar Mining Process

The feldspar mining method differs based on the type of feldspar mined. The procedure often entails drilling and blasting the rock into smaller pieces, which are then delivered to a processing factory. The processing plant crushes and processes the feldspar into a fine powder. Depending on end use, screening or flotation can separate feldspar into different grades or sizes.

In some cases, we can mine feldspar from open pits or quarries, while in other cases underground mining is required. We adjust the mining method used, according to parameters such as deposit depth, feldspar quality and mining cost.

It is essential to remember that feldspar mining and processing has a negative impact on the environment. These negative impacts include soil erosion, water pollution and habitat destruction. As a result, it’s critical that mining businesses adhere to best practices and laws to reduce their environmental effect.

Required equipment for feldspar mining

Depending on the deposit and the specific mining operation, feldspar mining may require different equipment. However, the following is a list of frequently used feldspar mining equipment:

- Excavators: Excavators are substantial tools we use for digging and removing overburden, the dirt and rock that cover the deposit.

- Crushers: Feldspar deposits usually occur in large chunks. We usually use a crusher to break them into smaller pieces for processing.

- Conveyors: The role of this device is to move feldspar from one place to another in mining operations.

- Screens: To separate feldspar by size and achieve more efficient processing, we usually use screens.

- Magnetic separators: We can use a magnetic separator to remove iron from feldspar.

- Flotation cells: We use flotation cells to separate feldspar from other minerals and contaminants.

- Grinding mills: We use grinding mills to further process the feldspar into fine powder. The subdivision of feldspar has several uses.

It’s important to keep in mind that depending on the specific mining operation and the type of feldspar mined, we may require additional equipment.

Expand knowledge: Feldspar crusher

SBM provides professional crushers for feldspar crushing with optional equipment. Our crushing equipment will meet your requirements for fineness and energy consumption.

In addition, we supply feldspar processing equipment with original drawings and design details for the complex, including crushing, grinding, screening and separating machines. You can choose feldspar jaw crusher, feldspar cone crusher, impact crusher or mobile feldspar crusher according to your requirements.

What’s next? Should it be feldspar processing? What is the process of feldspar processing?

Feldspar Processing

Complete feldspar solutions for all beneficiation and upgrading applications, including classification, agitation, flotation, magnetic separation, settling and filtration of feldspar. The chemical and physical characteristics of feldspar determine its processing methods. Here are a few typical techniques for processing feldspar:

- Crushing and grinding: We usually use crushers and mills to crush and grind feldspar into tiny particles for processing. This aids in increasing the mineral’s surface area, which facilitates the separation of impurities from feldspar.

- Magnetic separation: Magnetic separation can separate feldspar from other minerals. We place the mineral assemblage in a magnetic field. Magnetic separation achieves this by attracting feldspar and separating it from other minerals.

- Flotation: Flotation is a typical method for separating feldspar from other minerals. We pour the mineral mix into flotation cells and add chemicals to create a on top of the mix. Afterwards, we recover the feldspar from the layer.

- Gravity separation: We can separate feldspar from other minerals using techniques such as gravity separation. This principle works by creating a density difference in the tank such that feldspars sink to the bottom and other minerals float to the top.

- Drying and sizing: After we separate the feldspar from other minerals, this equipment dries and grades it to meet the requirements of different industries.

We have to process feldspar through multiple stages to separate it from other minerals and prepare it for use in different industries.

Required equipment for feldspar processing

Depending on the type of feldspar being processed and the desired end result, we may require a variety of equipment. In the process of feldspar processing, we often use the following equipment:

- Crushers: Used to break up big feldspar boulders into smaller particles for subsequent processing.

- Grinding mills: Grinding mills process feldspar into a fine powder. The choice of mill type depends on the final product as well as the hardness and moisture content of the feldspar.

- Magnetic separators: Used to separate feldspar from impurities that include iron. This is critical because iron impurities can contaminate the finished product and alter its properties.

- Flotation machines: In mineral deposits, flotation machines separate feldspar from other minerals.

- Hydrocyclones: Used to separate fine and coarse particles from a slurry.

- Drying equipment: We use drying equipment to remove moisture from the feldspar before further processing.

- Bagging equipment: This is the equipment that can pack the finished product for shipping.

These are only a few examples of machinery used to treat feldspar. The kind of feldspar being processed and the desired outcome will define the specific equipment needed.

Expand knowledge: Feldspar Mill

The feldspar powder production line contains a complete mill complex, including mill, classifier, cyclone and permanent magnetic shaft separator.

The main uses of feldspar powder are plastics, ceramics, enamel, white cement, and abrasive industries. Powder feldspar factory supply powder less than 200 mesh for these industries.

Grinding feldspar is the process of grinding powder and powder. In the process of grinding feldspar particles are ground into powder with a fineness requirement of 200 mesh in the mill. Then we use a magnetic separator to separate iron-bearing materials. According to different feldspar, we choose different useful feldspar processing method, such as gravity concentration and flotation.

If you are interested in feldspar crusher or feldspar mill price, please contact us online consultant!

Equipment configuration of feldspar mining and processing production line

- PE750 deep cavity heavy jaw crusher (1 set)

- HPT300 multi cylinder hydraulic cone crusher (1 set)

- PFW1315III European hydraulic three cavity impact crusher (1 set)

- MTW european trapezium grinding mill (1 set)

- S5X vibrating screen

- F5X vibrating feeder

- B6X belt conveyor

The Importance of Feldspar in Different Industries

- Ceramics: In the manufacture of ceramics, such as pottery, tableware, and bathroom fittings, feldspar plays a crucial role. It serves as a fluxing agent, lowering the melting point of ceramic materials and enhancing their toughness.

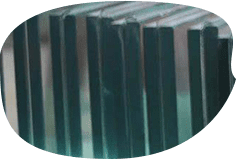

- Glass: Feldspar is a crucial component in the creation of glass, especially when it comes to the creation of flat glass, glass fiber, and glass containers. It offers durability, strength, and thermal shock resistance.

- Paints & coatings: The role of feldspar in the manufacture of paints and coatings is filler and extender. It increases the paint or coating’s tensile strength, durability, and abrasion resistance.

- Plastics and rubber: Feldspar is a filler that is used in plastic and rubber goods to increase strength and chemical and heat resistance.

- Electronics: Due to its excellent dielectric strength and thermal shock resistance, another important role of feldspar is in the production of electronic components, including capacitors, resistors and spark plugs.

In general, feldspar is a significant mineral that is essential to many different businesses. Due to its special qualities, it is an important ingredient in the creation of many items that we use on a daily basis.

Social Impact of Feldspar Mining and Processing

Feldspar mining and processing may have both positive and negative social consequences on local populations. The following are some of the potential societal consequences of feldspar mining and processing:

- Employment: Mining and processing feldspar can offer jobs in rural areas where work may be rare. This can improve the quality of life for local citizens while also assisting the region’s economic development.

- Land use and displacement: Feldspar mining has the potential to uproot local communities and alter their traditional land-use patterns. This might lead to disputes over land ownership and use.

- Health and safety: Feldspar mining and processing can put workers’ health and safety at risk, particularly if the proper safety measures are not performed. Exposure to dust and other harmful compounds can cause respiratory problems, skin irritations, and other health issues.

- Water use and contamination: The mining and processing of feldspar may use a significant amount of water, which might limit the local population’s access to water supplies. Furthermore, improper trash removal can contaminate water sources, which is bad for the environment and for people’s health.

- Community engagement: It is vital for mining companies to interact with and respect the rights and interests of area communities. Sharing knowledge about the consequences of mining and processing activities, talking with local residents about resource management and land use, and supporting regional development projects are all examples of what this entails.

Overall, the social implications of feldspar mining and processing are complex and depend on a variety of elements, including the mine’s location, size, and the laws and procedures of the mining business. It is critical to ensure that mining activities are carried out in a sustainable manner that respects the rights and interests of local residents.

In Conclusion

Several industries rely significantly on feldspar mining and processing, including ceramics, glass, paints and coatings, plastics and rubber, and electronics. In the mining and processing of feldspar, after exploration and extraction, it is crushing, grinding, separation, purification and packaging. While ethical mining practices can help local economies thrive and provide employment, they can also have a negative impact on society and the environment if not done in an ethical and sustainable manner.

Some of the social implications of feldspar mining and processing include employment opportunities, land use and displacement, health and safety concerns, water use and contamination, and community engagement. Mining companies must connect with the community and respect the rights and interests of its employees. Sharing knowledge about the consequences of mining and processing activities, talking with local residents about resource management and land use, and supporting regional development projects are all examples of what this entails.

The mining and processing of feldspar can have significant environmental consequences such as soil erosion, deforestation, biodiversity loss, and air and water pollution. Mining companies must implement environmental management techniques and reduce the environmental impact of their activities. Reduced trash generation, conservation of water resources, use of renewable energy sources, and adoption of sustainable land use techniques are a few examples.

In general, feldspar mining and processing are critical to the creation of many everyday items. To guarantee that mining activities are carried out ethically and sustainably, the economic benefits of mining must be balanced against the social and environmental costs. Mining businesses may help the local economy, safeguard the environment, and secure the long-term profitability of their operations by employing ethical mining procedures.