Email: [email protected]

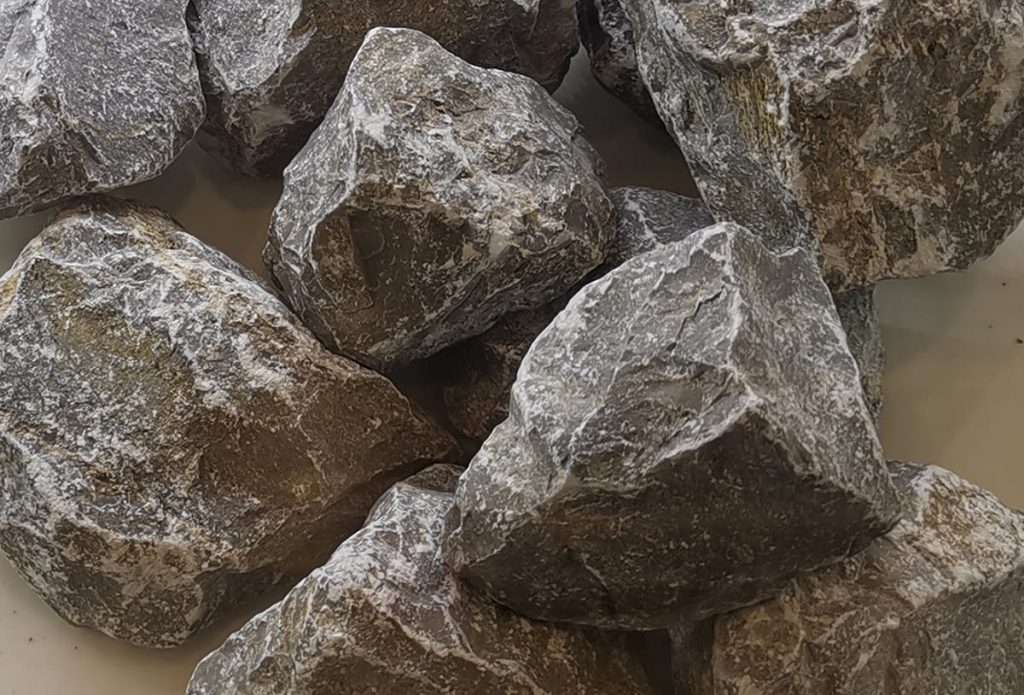

How Is Crushed Limestone Produced?

Crushed limestone is produced by crushing and screening limestone rocks or aggregates into various sizes. Usually, there are numerous phases to the process, including quarrying, crushing, screening, and washing. Here is a step-by-step breakdown of the procedure for creating crushed limestone:

- Quarrying: Limestone comes from mines or quarries. We first remove chunks or limestone fragments from the crust using drill and blast methods. Depending on the particular quarry, the size of these chunks might vary.

- Primary crushing: The first crusher (usually a jaw crusher or gyratory crusher) breaks the extracted limestone into smaller pieces. The limestone is first crushed into workable pieces.

- Secondary crushing: The crushed limestone from the primary crusher can go to secondary or tertiary crushing stage if we need further size reduction. We can accomplish these stages by using hammer mill, cone crusher or impact crusher.

- Screening: After crushing, the broken limestone passes through screening equipment to separate aggregates of various sizes. For this process we often use a shaker or multiple screens. Smaller particles can flow through the screens while the bigger ones are kept for additional crushing or processing.

- Washing (optional): Crushed limestone may go through a washing procedure to get rid of pollutants, dust, or particles depending on the intended usage and quality standards. This is particularly crucial when using limestone to produce concrete, for example.

- Sorting and storage: We divide the screened and washed crushed limestone into various sizes according to the requirement. Then we stack or store it for a specific purpose.

What is crushed limestone used for?

- Construction and Infrastructure: In construction projects, crushed limestone is often the base material and aggregate. It gives parking lots, roadways, driveways, and foundations stability, strength, and durability.

- Concrete and Cement Production: A crucial ingredient in the production of cement and concrete is crushed limestone. It serves as a filler, giving the finished product strength and stability. To make concrete for buildings, bridges, and other construction, we combine it with cement, sand, and water.

- Landscaping and Gardens: To create beautiful and functional outdoor environments, we often use crushed limestone in landscaping projects. It can act as a ground cover to prevent weed growth as well as for walks, garden borders and rock gardens.

- Drainage and Erosion Control: Crushed limestone works well for drainage purposes because it is porous. It speeds drainage around French gutters, septic drain areas and downspouts. Additionally, it aids in preventing soil erosion on embankments and slopes.

- Agricultural and Soil Amendment: To improve soil conditions, we often use the broken limestone in agricultural applications. It restores balance to acidic soils, supplies vital calcium and magnesium minerals, and encourages the growth of healthy plants. Additionally, it serves as a calcium supplement in animal feed.

- Water Treatment and Purification: To balance the pH and get rid of contaminants, water treatment procedures use crushed limestone. Acidic mine drainage and municipal water treatment facilities frequently employ it.

- Industrial Applications: There are several industrial uses for broken limestone. It serves as a flux in the manufacture of steel, as a raw material in chemical reactions, and in the creation of glass. Additionally, it serves as a filler in goods like plastics, paints, and coatings.

What are the different sizes of crushed limestone available?

- Dust/Screenings: This is the highest grade of crushed limestone, often known as limestone screens or dust. It comprises of microscopic particles, often less than 3/16 inch (4.75 mm). We often use dust or screens as a bedding material for laying flagstones, as a screed for pavers, or as an ingredient in concrete mixes.

- 3/8 inch (9.5 mm): Driveways and pathways made of gravel frequently use this size. It consists of limestone fragments ranging in diameter from about 3/8 inch (9.5 mm) to fine dust. For walking and driving, the smaller size offers a smoother surface.

- 1/2 inch (12.7 mm): We often use crushed limestone of this size as backfill around underground pipes, as a foundation for terraces and retaining walls, and for drainage works. It has a diameter that goes from about 1/2 inch (12.7 mm) down to very small particles.

- 3/4 inch (19 mm): We sometimes refer to this dimension as “limestone” and use it extensively in landscaping and architectural projects. It is often the base material for parking lots, sidewalks and roads. The particles’ diameters generally range from 3/4 inch (19 mm) to very small ones.

- 1 inch (25.4 mm) and larger: Larger building and landscaping projects frequently employ crushed limestone in this size range. We use it to build drainage systems, backfill retaining walls, and as foundations for highways.

If you also want to know about the size and use of crushed stone, please visit crushed stone size chart.

How much does crushed limestone cost?

We generally price crushed limestone by the ton or cubic yard. Depending on the grade and size of the broken limestone, costs in the United States might range from $20 to $50 per ton (2,000 pounds) or from $10 to $25 per cubic yard. Remember that there can be extra fees for delivery, shipping, or specialty mixes.

The price of crushed limestone can vary based on a number of variables, such as the type of limestone used, the location of the quarry, the distance from the quarry to the area where the material will be delivered, and the required amount of material. Prices can also change over time as a result of changes in the market and other economic considerations. The easiest way to obtain precise and current price information for broken limestone in your region is to speak with nearby suppliers or contractors.

Contact nearby quarries, landscape supply firms, or building material suppliers to obtain the most precise cost information. Depending on where you are located and what your project needs, they will be able to give you relevant price information.

If you are interested in crushed limestone crusher or mill, you can have a free consultation with our online staff or local offices.