Email: [email protected]

Crushed Calcite

Home » Crushed Stone » Crushed Calcite

Main Contents

Forget the glitter for a second. Real industrial muscle often comes dressed in plain white powder. Take crushed calcite – that unassuming stuff born from ancient seafloors. It’s the silent backbone of things you touch daily, from the smooth paper in your printer to the vibrant paint on your living room wall. This isn’t just a geology lesson; it’s a deep dive into why this mineral matters, how we wrestle it from rock into powder, and why getting the processing right makes or breaks its value. Let’s crack open the potential locked inside this deceptively simple material.

What Is Crushed Calcite? (And Why It Actually Matters)

At its core, crushed calcite is simply natural calcium carbonate rock that’s been broken down into pieces. You’ll find it everywhere – it’s a key part of limestone and marble formations worldwide, a basic building block of the Earth itself. But here’s the important part: that raw rock isn’t very reactive on its own. The real value comes when we crush and grind it. Picture this: huge, tough rocks turned into a fine, useful powder. That crushing process releases its best features – its bright white color, consistent chemistry, relative softness, and many uses. Truthfully, it’s one of nature’s handiest materials, but only if we handle it correctly.

The Real-World Properties Driving Calcite Demand

So, what’s the big deal about ground calcite? It’s not hype; it’s a solid combination of inherent traits that industries rely on:

- Brilliant Whiteness & High Brightness: Top-shelf crushed calcite offers a naturally bright white base. This makes it a killer, cost-effective filler and pigment extender. It literally makes things whiter and brighter without breaking the bank.

- Tight Particle Size Control: Modern milling isn’t guesswork. We can dial in the fineness of calcite powder with impressive precision – from chunky aggregates for construction down to ultrafine fillers for premium paints and plastics. It’s all about matching the powder to the job.

- Chemical Consistency: Good sources produce very pure calcium carbonate powder. This steady quality is extremely valuable for sensitive products like food additives or medicines where unexpected changes cause problems.

- Low Hardness (Mohs 3): This relative softness is a major plus. Compared to harder minerals, calcite is simply easier and cheaper to crush and grind. That translates directly to lower energy bills – a very practical advantage.

- Surface You Can Tweak: The surface chemistry isn’t set in stone (pun intended). We can treat it, often with stearic acid, to make it water-repellent (hydrophobic). This is crucial for getting it to mix smoothly into plastics and stops it from clumping due to moisture. Clever stuff.

Table 1: What Industry Looks for in Crushed Calcite

| Property | Typical Value/Characteristic | Why Buyers Care |

|---|---|---|

| Chemical Makeup | >98% CaCO₃ | Means consistent performance and safe for sensitive uses. |

| Brightness | 90-96% (ISO) | Directly impacts how white the final product looks. |

| Hardness (Mohs) | 3 | Less wear on equipment, lower energy needed to process. |

| Specific Gravity | ~2.7 | Affects how much you can pack into a composite material. |

| Oil Absorption | Medium (~15-25 g/100g) | Influences how much resin or binder it needs (can be modified). |

| Refractive Index | 1.49-1.66 | Affects how it scatters light, important for opacity in paints/plastics. |

From Rock to Reliable Powder: The Calcite Production Line

Making consistent, high-quality crushed calcite isn’t alchemy; it’s solid engineering and process control. Here’s the journey, step by gritty step:

1. Getting it Out of the Ground

It starts at the quarry. We target seams of high-purity calcite rock – limestone, marble, sometimes chalk. Blasting or careful excavation gets us large blocks. Selective mining is key; garbage in equals garbage out.

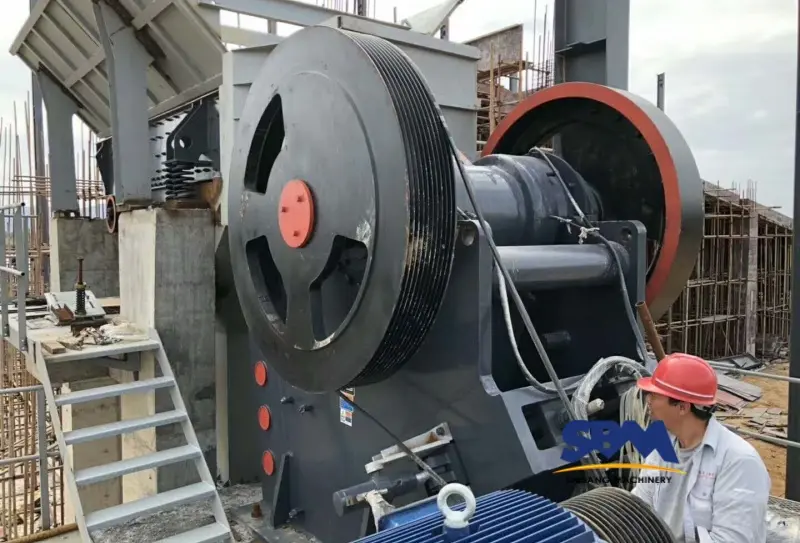

2. The First Break (Primary Crushing)

Massive rock blocks meet powerful jaw crusher. These reduce rocks to 6-10 inch chunks. This initial break affects all later steps – impressive to witness.

3. Refining the Size (Secondary & Tertiary Crushing)

The chunks need further reduction. Cone crusher or impact crusher takes over here. This staged approach gets us closer to the target size (often 0.5-2 inches) before the fine grinding begins. Choosing the right crusher here is critical for getting the particle shape you need and minimizing unwanted fines early on.

4. The Fine Art of Grinding

This is where coarse aggregate transforms into valuable calcite powder. The tech varies depending on how fine you need to go:

- Ball Mills/Rod Mills: The old reliables, great for coarser grinds. Robust but not always the most energy-sipping. Get more information & price

- Vertical Roller Mills (VRM): These are workhorses for efficiency, especially for finer grades. Lower energy consumption is a major selling point.

- Raymond Roller Mills: A classic choice for producing medium-fine powders. Familiar tech for many plants.

- Classifier Mills: These combine grinding and air classification in one unit. Fantastic for ultra-fine powders where you need super tight control over particle size distribution. The precision achievable now is a game-changer.

5. Sizing it Right (Classification)

Air classifiers act like high-tech sieves in the sky. They sort particles by size. Oversized bits get sent back for more grinding. This loop ensures the final ground calcite meets the exact size specs demanded by customers. No guesswork.

6. Tailoring the Surface (When Needed)

For applications where water resistance is crucial (like many plastics), the dry powder gets treated. Special mixers coat the particles with agents like stearates, making them hydrophobic. This step adds value.

7. Bagging and Shipping

The finished crushed calcite – now a valuable commodity – gets stored in silos. Then it’s off to customers in bulk trucks, massive supersacks, or smaller bags. Seeing those mountains of pure white powder ready to roll out always feels like a job well done.

The Crusher: Heart of the Calcite Operation

The unsung hero in this whole process? The calcite crusher. Picking the right crushing gear isn’t just about brute force; it’s about efficiency, controlling particle shape, managing how much fine dust you make too early, and ultimately, your cost per ton. Here’s the lineup:

- Jaw Crushers: The absolute anchors for primary crushing. Think toughness and high capacity for dealing with the big stuff straight from the quarry. Brands like SBM China offer robust designs with deep chambers specifically set up for hard rock like calcite.

- Cone Crushers: Indispensable for the secondary and tertiary stages. They excel at producing well-graded, cubical particles – absolutely vital for construction aggregates made from coarser crushed calcite. Features like hydraulic adjustment (common in SBM models) make them reliable and easier to maintain.

- Impact Crushers (HSI/VSI): These are your go-to for shaping. Horizontal Shaft Impactors (HSI) or Vertical Shaft Impactors (VSI) are great for getting specific particle shapes, like nice cubical aggregate or sand-like material. VSIs are particularly good for fine control and shaping. Essential when the shape of the particle matters as much as the size.

Table 2: Matching the Crusher to the Calcite Crushing Stage

| Crusher Type | Where It Shines | Key Strengths | Best Suited For | Watch Outs |

|---|---|---|---|---|

| Jaw Crusher | Primary Reduction | Handles big rocks, simple design, high capacity, tough. | First step after quarry, breaking down large blocks. | Less precise control over final particle shape. |

| Gyratory Crusher | Primary Reduction | Massive capacity, continuous feed, handles abrasion well. | Huge mining operations needing maximum throughput. | Higher upfront cost, more complex to maintain. |

| Cone Crusher | Secondary/Tertiary | Excellent for cubical shape, adjustable output size, efficient. | Producing quality aggregates, feeding grinding mills. | Needs consistent feed size to perform optimally. |

| Horizontal Shaft Impactor (HSI) | Secondary/Tertiary | High reduction ratio, good on softer rock, uniform product. | Recycling, softer limestone, certain shape needs. | Wear costs can be higher on very abrasive material. |

| Vertical Shaft Impactor (VSI) | Tertiary/Shaping | Unbeatable particle shaping, makes sand, controls fines. | High-quality manufactured sand, shaped aggregates. | Higher energy use, moisture in feed can cause issues. |

Choosing Your Calcite Crusher: Cutting Through the Noise (SBM China Perspective)

Sorting through crusher options can be challenging. Trusted makers like SBM China provide complete setups. Focus on what truly counts:

- Throughput & Feed Size Match: Does the crusher’s capacity and max feed size align with your quarry output and the rock size you’re feeding it? Bottlenecks at the crusher are expensive headaches.

- End Product Goals: What size and shape do you need? Cone crushers are shape masters. VSIs offer ultimate shaping finesse. Your market dictates the specs.

- Rock Characteristics: Calcite is somewhat soft but wears down equipment. Verify wear part quality (mantles, concaves, blow bars). High-wear-resistant steel parts are essential. Frequent part replacements hurt profits – SBM’s durable designs prevent this.

- Running Costs (Energy): Modern crushers (like SBM’s cone/jaw models) use less power per ton. Energy is a major operating expense – efficiency matters.

- Brains & Control: Modern crusher isn’t foolish iron. Advanced control systems optimize performance, prevent overload damage, and allow remote monitoring. This means better efficiency and smarter maintenance planning.

- Support You Can Count On: Consistent service, expert help, and ready parts are critical. Your crushing line halts without them. Suppliers like SBM China build trust through dependable support – never overlook this.

Where Does This Mountain of Powder Go? (Hint: More Places Than You Think)

The sheer scale of global crushed calcite consumption is mind-boggling. Its versatility is its superpower:

1. Paper: The Biggest Player by Far

Millions of tons of Ground Calcium Carbonate (GCC) disappear into paper mills yearly. It’s a filler and coating pigment that boosts brightness, opacity, smoothness, and printability, all while reducing the cost of the paper itself. Essential.

2. Plastics: The Versatile Reinforcer

A superstar filler and performance modifier. Calcium carbonate powder adds stiffness, improves dimensional stability, raises heat resistance, and can even enhance impact strength in some composites. Surface-treated grades mix better and reduce the amount of expensive plastic resin needed. Think PVC pipes, window profiles, packaging films, car parts. It makes plastics perform better and cost less – a rare win-win.

3. Paints & Coatings: The Workhorse Extender

Especially the fine and ultrafine grades. Crushed calcite bulks up paint, provides crucial opacity (hiding power), helps control the flow (rheology), improves durability, and keeps costs manageable for both water-based and solvent-based paints. That fresh coat on your walls? Packed with calcite.

4. Building the World (Construction)

Coarse grades form concrete, asphalt, and building blocks. Fine powders strengthen tile glue, sealants, and drywall compounds. Literally builds our world.

5. Growing Food (Agriculture)

Finely ground powder is agricultural lime. Farmers apply it to balance acidic soil and deliver essential calcium to crops. Foundation of healthy harvests.

6. Making Glass

High-purity calcite provides critical calcium oxide. This dramatically lowers sand’s melting point, making bottle, window, and fiberglass production possible.

7. Cleaning Our Act (Environmental)

Used in massive quantities for Flue Gas Desulfurization (FGD) at power plants to scrub sulfur dioxide out of emissions. Also used in water treatment plants to adjust pH and remove impurities. Calcite helps keep air and water cleaner.

8. Food & Pharma: The Purest Form

Extremely pure, food-safe calcium carbonate powder has many uses. It adds calcium to vitamins and foods with added nutrients. It’s in heartburn medicines to settle your stomach. It controls acidity in some products. It also whitens items like chewing gum and powdered sugar. Meeting strict purity and safety standards is the most important thing.

Table 3: Particle Size – The Make or Break Detail for Calcite Applications

| Where It’s Used | Typical Particle Size Needed (d97 or similar) | What It Does There | Critical Specs Beyond Size |

|---|---|---|---|

| Paper Filling | 1.5 – 3 microns | Adds bulk, improves brightness & opacity, makes surface smoother. | Must be very bright and gentle on papermaking machinery. |

| Paper Coating | 0.7 – 2 microns | Creates ultra-smooth surface, enhances gloss & print quality, boosts opacity. | Needs extreme fineness, tight size spread, top brightness. |

| Plastics (Filler) | 1 – 20 microns (varies wildly) | Increases stiffness, lowers cost, improves dimensional stability. | Surface treatment (stearate coating) often essential for good mixing. |

| Paints (Extender) | 0.7 – 10 microns (gloss level dictates) | Provides hiding power, controls sheen & flow, improves durability, reduces cost. | Must disperse well and be chemically stable in the formula. |

| Construction (Aggregate) | < 5mm (coarse sand to fine gravel) | Acts as bulk filler, contributes to structure. | Consistent gradation, clean (low clay/dust). |

| Agriculture (Lime) | < 0.5mm (finer = faster reaction) | Neutralizes soil acidity, supplies calcium to plants. | Reactivity (directly tied to fineness), purity. |

| Food/Pharma Grade | 5 – 15 microns (supplements), finer for other uses | Calcium source, antacid, whitener, pH control. | Ultra-high purity (strict limits on heavy metals), certified safe. |

| Glass Batch | Specific chemical specs matter most | Source of the essential CaO flux component. | Very high CaCO₃ content, very low iron/magnesium/silica. |

What’s Next for Crushed Calcite? (Beyond the Basics)

The crushed calcite world isn’t standing still. Here’s what’s shaping its future:

- Pushing Fineness Limits: Demand keeps growing for super-fine and nano-sized calcium carbonate powder. Top-quality plastics need better durability, paints want higher shine, advanced rubber requires better performance, and specialty papers demand finer fillers. Meeting these needs requires advanced grinding/sorting technology – and these premium products sell for higher prices.

- Surface Modification Becomes Standard: Just selling plain powder isn’t enough for high-value uses. Changing the powder’s surface to work perfectly with specific plastics or materials is becoming standard practice. This customization is now part of the basic product offering.

- Sustainability Moves Center Stage: Saving energy (like using efficient VRM mills), cutting water use, reducing waste (using quarry leftovers), and improving shipping methods are top goals. Efficient crushers and mills are key to reducing environmental impact. Customers actively seek these eco-friendly solutions.

- Consistency is King (Traceability Too): Buyers insist on getting the exact same quality every time – particle size, whiteness, and chemical makeup must stay identical. Differences between batches are unacceptable. This requires top-tier quality control systems and tracking materials from quarry to customer is becoming standard.

- Asia-Pacific Drives Growth: While global, the fastest growth is in Asia-Pacific fueled by massive industrialization and construction booms. Finding reliable local partners for equipment and supply, like SBM China, is a strategic advantage.

Picking Your Crushed Calcite Supplier: Look Beyond the Data Sheet

Choosing where to buy your crushed calcite involves more than just comparing technical specs on paper. Dig deeper:

- Proven Consistency: Can they reliably hit your specs batch after batch, month after month? Fluctuating quality wrecks your production consistency. Ask for records.

- Real Technical Muscle: Do they have experts who truly know your industry? Can they help solve problems or improve your product formulas? This support partnership is extremely valuable.

- Security of Supply: Do they have sufficient raw materials and production capacity? What’s their plan if equipment fails? Your production stops if their supply runs out.

- Smart Logistics & Packaging: How well do they handle bulk shipments? Do their packaging options (big bags, small bags) match your facility’s equipment? Poor delivery systems create hidden expenses and headaches.

- Investing in Tomorrow: Are they developing new products, finer powders, or eco-friendly methods? Choose suppliers focused on innovation, not just maintaining current operations. This protects your supply chain long-term.

The Humble Mineral That Builds Our World

Crushed calcite isn’t just ground-up rock. It’s a key material that works quietly to make many everyday items work better, look good, and stay affordable. Think about the paper you hold, the plastic parts in your vehicle, the paint on your house, or the glass in your window. Crushed calcite is in all of them. It’s everywhere and truly necessary.

Understanding how it’s made – starting with the powerful crush of a calcite crusher and ending with the careful sorting by air – shows the smart engineering needed to create this useful powder. Using the right machines, like efficient crushers and mills from trusted companies like SBM China, is vital.

Working with suppliers who truly understand what industries need allows businesses to fully use the amazing, real-world power of crushed calcite. It proves how changing the Earth’s raw materials moves things forward.

Next time you see something bright white, perfectly smooth, or built to last, remember the quiet journey of crushed calcite. This powerful little grain helps make modern life work.