Correo electrónico: [email protected]

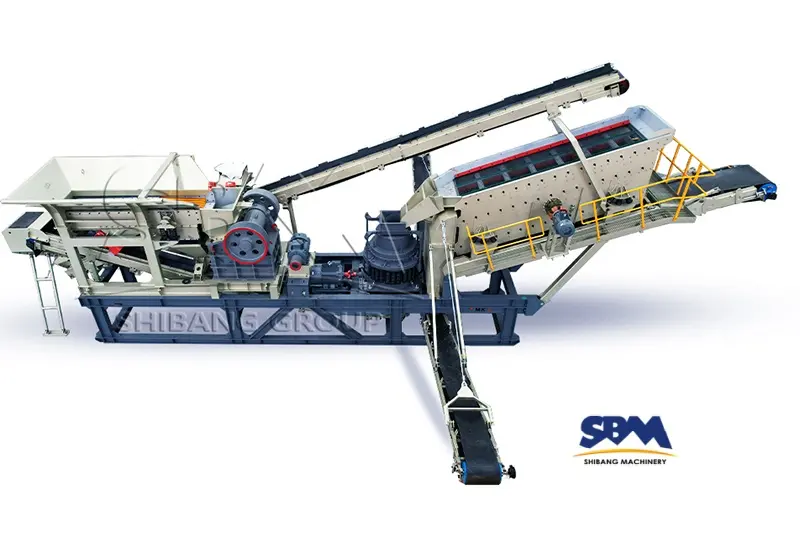

Trituradora y criba semimóvil MK

In the quickly changing world of mining, mineral processing, agregados, y reciclaje, producers face a key question: how to stay efficient and flexible while controlling costs? The MK Semi-mobile Crusher and Screen from SBM answers this challenge very well. It comes from years of engineering know-how and real-world feedback, and it is a modular system for crushing and screening that blends stability, mobility, and high performance. The MK system isn’t just about making crushing easy — it changes how industries handle material processing, from the mine to the stockpile. With modules that sit on their own bases, quick setup, and design options built to fit, operators can use it almost anywhere in 12–48 hours.

What Is the MK Semi-mobile Crusher and Screen?

El Trituradora y criba semimóvil MK combines the strong performance of fixed crushing equipment with the flexibility of portable units. Designed by SBM, a global leader in mining and construction machinery, this series focuses on quick deployment, easy relocation, and steady productivity.

Each MK station is made of independent skid-mounted modules—usually including a feeding system, a primary crusher, a screening module, transportadores, and a control system. These modules can be lifted, moved, and reassembled with minimal civil work.

Compared with traditional installations, where building a foundation can take weeks, the MK platform lets producers begin production in days rather than months. It represents a modular revolution in mobile crushing.

Key Design Advantages of the MK System

Foundation-Free Installation

Every MK module rests on anindependent skid-type frame, distributing weight evenly across a large ground area. This eliminates complex foundations, reduces setup time, and enables production on almost any stable surface.

12–48 Hour Rapid Assembly

With acombined modular design, the main parts can be lifted into position and linked through pre-built connections. Depending on the setup, the whole system can be ready to work within12 a 48 horas — a big advantage forshort-term mines or remote quarry sites that need quick output.

Superior Machine Quality and Reliability

Each MK unit includesSBM own crushers and screens, which are well-tested foreficiencia, long life, and easy care. These machines deliveralta capacidad, small space requirements, and consistent product size — all important for serious production work.

Intelligent and Convenient Maintenance

Elframe and platform design give plenty of room for maintenance work. Built-in ladders and walkways make operationssafe and simple, mientrasregular checks are quick and easy, even in tough on-site conditions.

Automatic Lubrication System

Each crushing unit has anautomatic oiling system that removes the need for regular manual greasing. This systemreduces labor time and oil use mientrashelping parts last longer.

The MK Series in Mining Applications

Designed for On-Site Ore Crushing

Mining projects often work in short-term or changing pit areas. The MK system’s semi-mobile setup allows it tomove quickly near the mining area, cutting transport costs and keeping machines running longer.

Powering Large-Scale Mineral Operations

Whether handling mineral de hierro, cobre, oro, o carbón, the MK Semi-mobile Crusher and Screen easily fits different mining needs. When combined with feeders and conveyor belts, it can turn an open-pit mine into a flexible and easy-to-move processing center.

Boosting Safety and Reducing Downtime

Unlike fully mobile tracked machines, the MK’s strong skid basestays steady even on uneven ground, reducing vibration-related wear and allowing forsafer and smoother operation under heavy use.

Mineral Processing: Improved Efficiency

In mineral processing plants, precision and control matter. The MK series brings both.

Each unit can fit directly into the mineral refining workflow, providing consistent sized material for grinding mills or flotation equipment. Its strong screening decks allow precise sorting and grading of materials for further processing.

Since all main machines come directly from SBM’s own factory, they fit together well and match in capacity. Operators can build mixed setups using other SBM products likeTrack-type Mobile Crushers oNK Portable Crushers for custom workflows.

- Related product link: Track-type Mobile Crusher

- Related system: Mobile Crusher Plant Overview

Aggregates Industry: Reliable, Móvil, and Scalable

A Perfect Fit for Quarry Operators

Producers in the aggregate industry often handle seasonal work, changing sites, and rising material needs. The MK Semi-mobile Crusher and Screen offers unmatched flexibility.

Operators can move it between quarries or temporary mixing locations, all while keeping product quality and output steady. It comes with many crushing chamber options, allowing it to work with sandstone, caliza, granito, o basalto without needing changes.

Sustainable and Efficient Production

With built-in dust control and smart energy use, the MK station runs cleanly and efficiently. This makes it ideal for modern aggregate producers who want to reduce carbon emissions and produce in a sustainable way.

Reciclaje: Turning Waste into Wealth

The construction and demolition recycling sector thrives on flexibility — and the MK series was designed with that in mind.

Concrete and Asphalt Recycling

The MK Semi-mobile Crusher and Screen handles mixed construction debris, concrete blocks, and asphalt efficiently. With its built-in screen module, the system separates fine and coarse fractions, producing reusable aggregates for road base and new concrete applications.

Urban and Industrial Applications

In cities where space is limited, the MK station offers compact, noise-controlled operations. Since it requires no fixed foundation, it can operate directly at demolition sites — turning waste into valuable recycled material.

Technical Highlights and Comparison Data

| Modelo | Tamaño máximo de alimentación | Capacidad (HTP) | Fuerza (kilovatios) | Setup Time | Ideal Application |

|---|---|---|---|---|---|

| MK-A | ≤800 mm | 100–500 | 250 | 12–24 hours | Aggregates, Reciclaje |

| MK-B | ≤900 mm | 150–600 | 315 | 24–36 hours | Medium-scale Mining |

| MK-C | ≤1000 mm | 200–800 | 400 | 24–48 hours | Large Mining, Mineral Processing |

Graphically, if plotted, production efficiency increases proportionally with model size, while setup time remains remarkably short — a key advantage of modular design.

Estudios de caso: Proven Performance Across the Globe

Granite Crushing in Ghana

SBM’s MK Semi-mobile system was used in Ghana’s granite mining area, where tough conditions needed a crusher that was both mobile and stable. The project showed excellent capacity while cutting setup costs by 40% compared to fixed systems.

60–80 TPH Production Line in Tanzania

This project in Africa showed fast movement and high productivity. Within two days of arrival, the station reached full production with few workers. Local contractors praised the consistent shape of the final product and the low maintenance required.

China’s Urban Construction Waste Recycling Programs

In mainland China, several MK units have been used in city recycling centers. By recycling broken concrete and asphalt, these centers greatly lowered landfill waste and provided sustainable aggregate material for new building projects.

Environmental and Economic Benefits

Eficiencia energética

SBM designed the MK platform to use fuel and energy wisely. Smart power controls and adjustable motor speeds reduce energy use, saving customers up to 10–15% on operating power compared to older machines.

Operational Cost Savings

The automatic oiling system and reduced need for foundations lower both labor and maintenance expenses. Together with long-lasting parts, these features reduce total operating costs by nearly 20%.

Sustainable Design

El Trituradora y criba semimóvil MK supports environmental goals with its dust control and noise reduction systems. It helps companies meet ISO14001 environmental standards and improve their ESG (environmental, social, and governance) performance efficiently.

Intelligent Control and Automation

Modern crushing operations require precise and data-based control. The MK system comes withsmart control panels that show live performance on dashboards and include safety sensors. Operators can control feed speed, motor power, and screening settings remotely.

This smart design keeps production steady and prevents overloads or sudden stops, which is especially valuable in tough mining conditions.

User Experience and Service Framework

One big advantage of working with SBM is its reliable service. Every MK customer gets:

- Project-specific advice and layout design

- Help with on-site installation and training

- Global parts supply and 24-hour online support

SBM’s network in more than130 countries ensures every plant runs at full capacity — no matter the terrain or weather.

How to Choose the Right MK Semi-mobile Crusher and Screen

- Identify Material Type: Determine whether you’re processing granito, mineral, or waste.

- Estimate Capacity Needs: Choose models aligned to daily tonnage (P.EJ., MK-A for <=500 TPH operations).

- Assess Mobility Requirements: For frequent relocation, smaller modular configurations are best.

- Integrate with Processing Line: Combine with feeders, transportadores, or grinding units for seamless flow.

Need professional advice? Visit the official SBM page for customized consultation:

SBM Official Page

Customer Benefits at a Glance

- No foundation required – quick setup and start

- Ready for full operation within 12–48 hours

- Safe design that’s easy to maintain

- Uses less energy and meets environmental standards

- Ideal for mining, agregar, y proyectos de reciclaje

- Backed by SBM’s global service and technology guarantee

Conclusión

El Trituradora y criba semimóvil MK is not just for moving rocks — it’s designed to move entire industries forward. By combining strength, simplicity, and smart mobility, SBM provides a crushing system made for the changing needs of modern operations.

Whether you’re working deep in a mine, operating a large aggregate plant, or recycling construction waste in the city, the MK series helps you spend less time setting up and more time producing.

To explore configurations, application cases, or request a quote,