E-mail: [email protected]

Comment choisir le bon concasseur à la mâchoire pour les opérations minières: Un guide complet

La sélection du concasseur à mâchoires approprié pour les opérations minières est essentielle pour obtenir un traitement efficace du minerai., minimiser les temps d'arrêt, et maximiser la productivité. Avec différents modèles, dessins, et spécifications techniques disponibles, comprendre les facteurs clés peut vous aider à prendre une décision éclairée. Ci-dessous, we break down the essential considerations for choosing the best jaw crusher tailored to your mining needs.

Assess Material Compatibility and Ore Characteristics

The type of material being crushed directly impacts the choice of jaw crusher. Par exemple:

- Hardness and Abrasiveness: Harder ores like granite or iron ore require crushers with high wear-resistant components, such as manganese steel plates, to withstand prolonged use.

- Taille de l'alimentation: Ensure the crusher’sfeeding opening size (Par exemple, 250×1000 mm to 1500×2000 mm) matches your raw material dimensions to avoid blockages and ensure smooth operation.

- Teneur en humidité: Opt for crushers with designs that tolerate moisture, especially if processing clay-rich or wet ores.

Determine Required Capacity and Output Size

Jaw crusher we choose the right one for mining operation as production capacity and final product size vary. Considérer:

- Production Goals: High-capacity models like the C6X200-1500×2000 can process up to 1,510 tonnes par heure, ideal for large-scale mining operations.

- Adjustable Discharge Settings: Look for crushers with adjustment systems to control output size (Par exemple, 20–300 mm) for downstream processing needs.

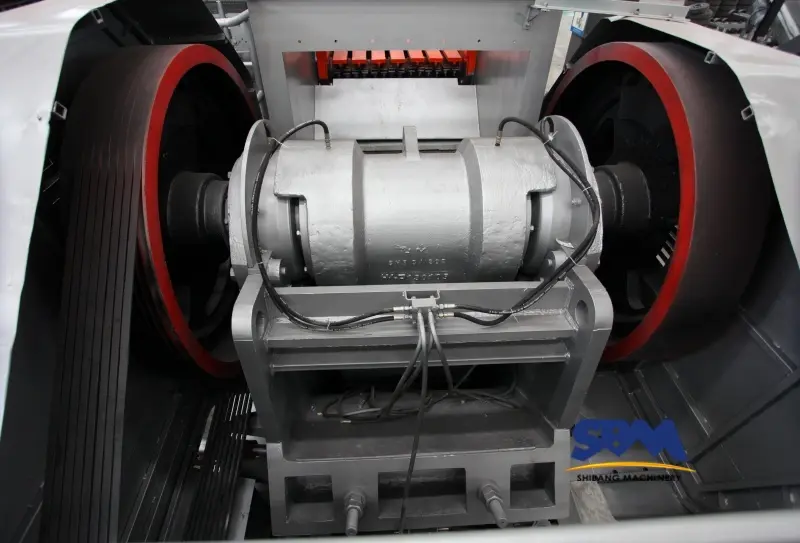

Evaluate Structural Design and Durability

A robust design ensures longevity and reduces maintenance costs:

- Frame Construction: Modular, non-welded frames (Par exemple, Série C6X) enhance fatigue resistance and operational reliability.

- Bearing Quality: High-performance rolling bearings reduce friction and extend service life, especially under heavy loads.

- Toggle Plate Strength: Double-toggle jaw crushers are better suited for abrasive materials, alors que single-toggle (PE) modèles offer simpler maintenance.

Prioritize Maintenance and Operational Safety

Maintenance régulière is crucial for sustained performance:

- Lubrication Systems: Choose the suitable jaw crusher for mining operations with centralized greasing systems to ensure consistent lubrication of bearings and toggle plates every 3–6 months.

- Ease of Access: Opt for designs with removable components for quick part replacement and inspection.

- Caractéristiques de sécurité: Verify compliance with ISO 9001 or OHSAS 18001 certifications to meet industry safety standards.

Compare Suppliers and Cost-Effectiveness

Partnering with reliable manufacturers ensures quality and after-sales support:

- Certifications: Prioritize suppliers with ISO 9001 certification and proven project experience (Par exemple, SBM Industrial Technology Group Co., Ltd.)

- Analyse des coûts: Balance upfront costs (e.g., 7,500–300,000 per unit) with long-term savings from energy efficiency and reduced downtime

- Custom Solutions: Some manufacturers offer tailored crushers for specific applications, tel que limestone or iron ore processing.

Optimize Your Mining Efficiency with the Right Jaw Crusher

Choosing the right jaw crusher for mining operations involves a careful evaluation of material properties, production requirements, and equipment durability. By prioritizinghigh-quality alloys, adjustable output settings, ettrusted suppliers, tu peux enhance crushing efficiency and reduce operational costs. For a detailed comparison of jaw crusher models and prices, contact us and start a free consultation to customize a solution for your unique needs.